Experiment method for detecting light fuel oil component content in aerooil

A technology of aviation lubricating oil and test method, which is applied in the test field of detecting the content of light fuel oil in aviation lubricating oil, can solve the problems of inability to judge low-boiling point mixtures, etc., save repair time, save manpower and material resources, and judge accurately high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

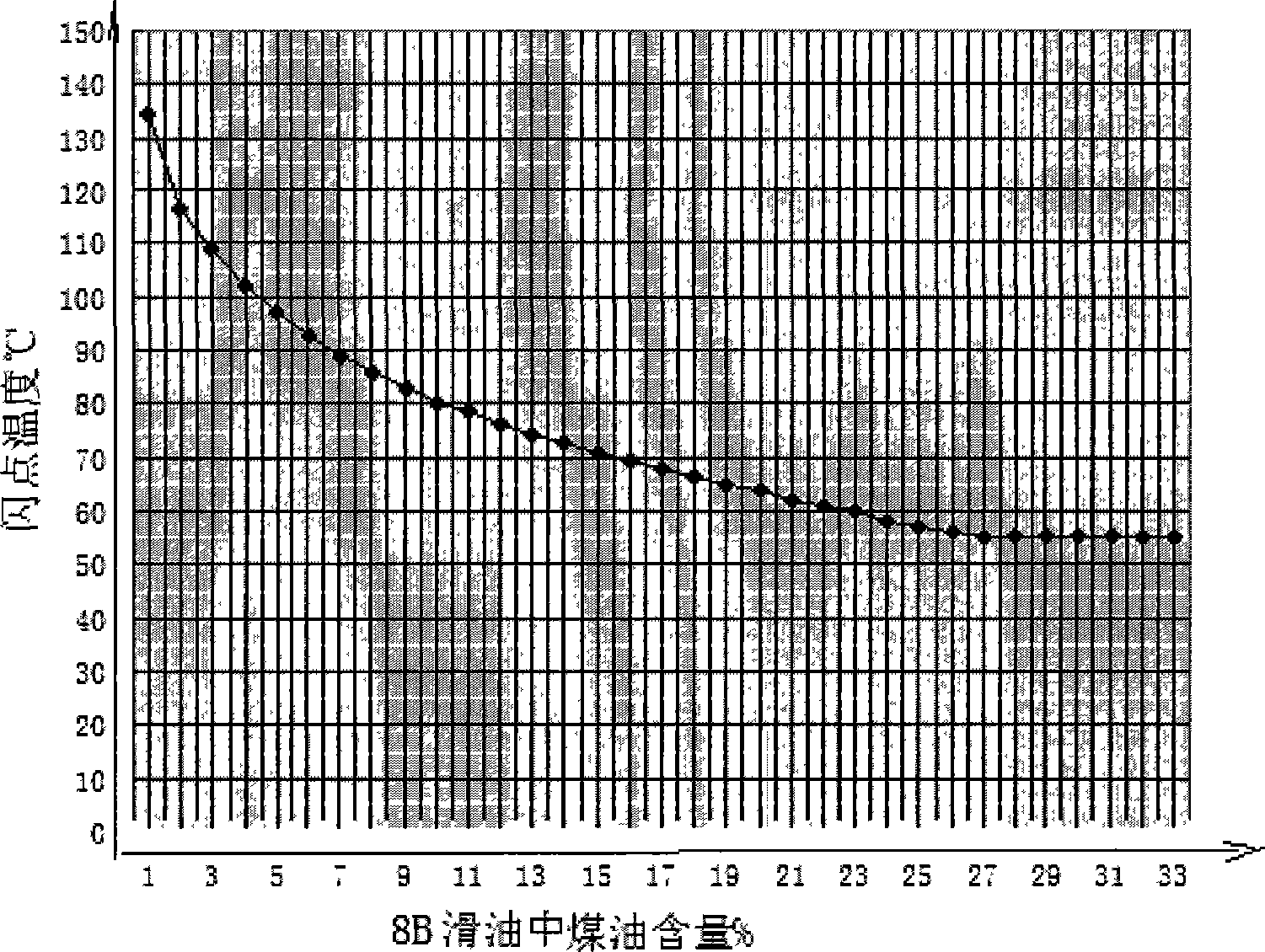

[0016] The content of light fuel components in aviation lubricating oil with grade 8B was determined by a closed flash point tester. The light fuel oil can be kerosene or No. 3 jet fuel. According to the present invention, can carry out as follows:

[0017] Unused kerosene and unused aviation lubricating oil were prepared into mixed test oils in different proportions. First weigh the mixed test oil samples prepared with mixed oils with different contents, stir them evenly, and let them stand for at least three days.

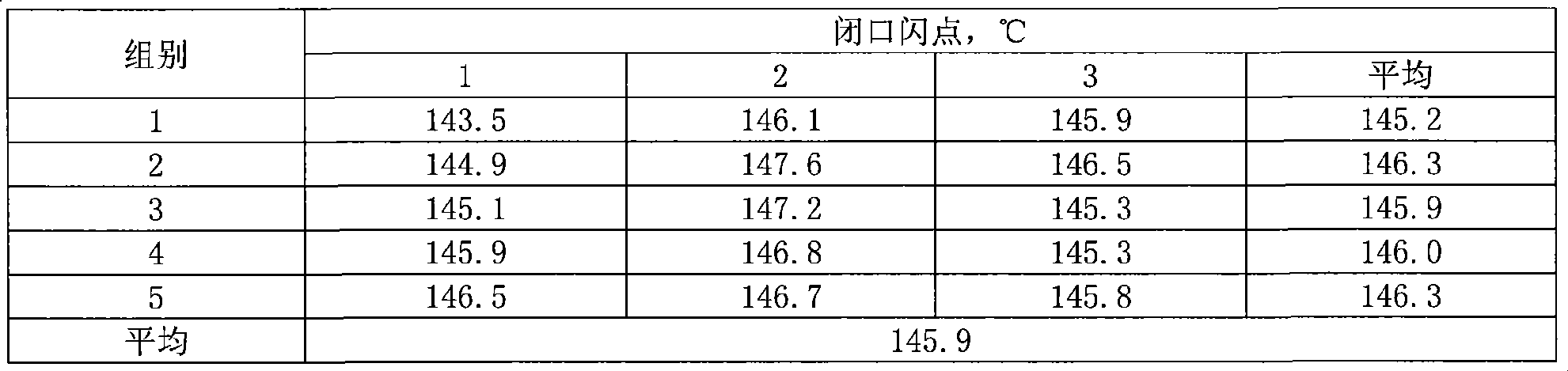

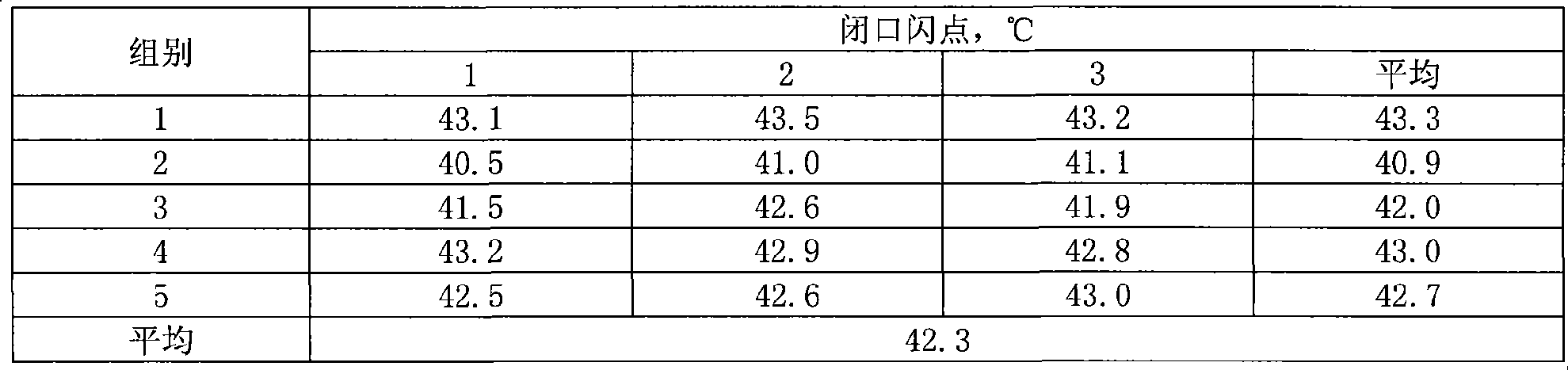

[0018] Determine raw flash point values for RP-3 and 8B. Randomly measure the closed flash point of RP-3 that entered the factory at different times (different production dates, batches, and manufacturers), measure different closed flash points, and find out the average flash point temperature of RP-3 based on these flash point values . Randomly measure the closed flash point of 8B that entered the factory at different times (different production dates, bat...

Embodiment 2

[0034] Determination of Light Components and Kerosene Contents in 8B Aviation Lubricating Oil by Distillation Range Tester

[0035] The distillation range of petroleum products refers to the relationship between the amount of oil that can be distilled from the petroleum product and the temperature within a certain temperature range. It uses the heating principle to heat the oil into steam, and then re-forms liquid through condensation. This distillation is conditional, and the amount distilled is only a relative comparison.

[0036] Due to the different components of different oil products, the light components evaporate quickly and only need a lower temperature to evaporate. On the contrary, the heavy components need a higher temperature to complete the distillation process. During the test, the cooling time of the test instrument is (30-60) min and the distillation time is 45 min, and the whole test takes about 2 hours. At the same time, because petroleum products are compo...

Embodiment 3

[0038] Determination of Light Components and No. 3 Jet Fuel in 8B Aviation Lubricating Oil by Measuring Method of Kinematic Viscosity

[0039] The method of measuring kinematic viscosity refers to measuring the time for a certain volume of liquid to flow through a calibrated capillary viscometer under gravity at a constant temperature. The product of the capillary constant of the viscometer and the flow time is the kinematic viscosity.

[0040] The standard stipulates that when measuring the kinematic viscosity, the constant temperature of the test must be determined first, and the constant temperature of the viscosity constant temperature tank must be kept constant for more than 15 minutes. Determine the viscosity tube according to the specified viscosity value of the product and ensure that the time through the capillary is not less than 200s.

[0041] In each test, the viscosity tube coefficient should be calculated first, and viscosity tubes with different diameters shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com