Axial variable displacement plunger pump of swash plate

A technology of axial piston pump and swash plate, which is applied in pumps, multi-cylinder pumps, liquid displacement machinery, etc., and can solve problems such as large moment of inertia of cylinders, difficulty in axial pressure balance, and pollution sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

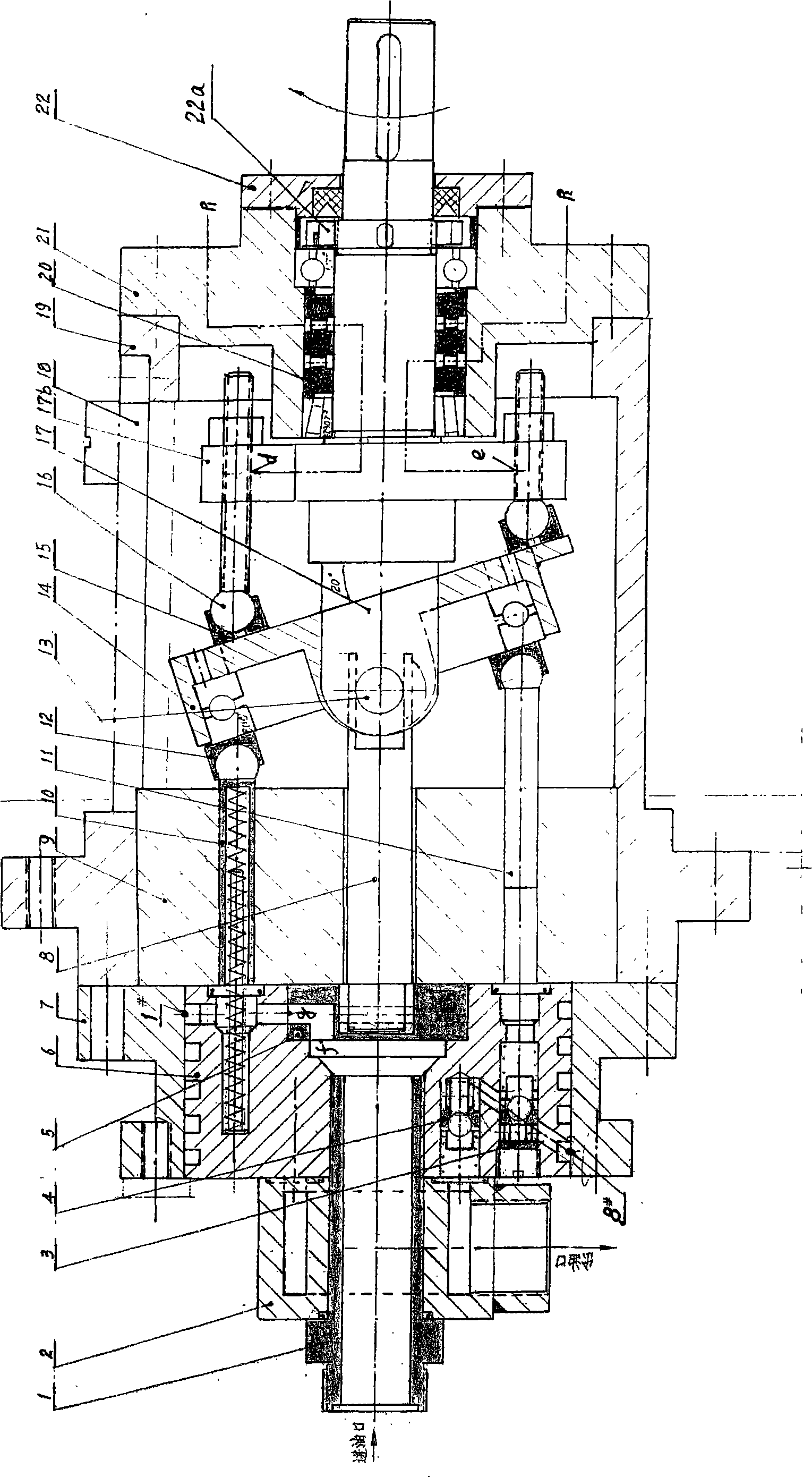

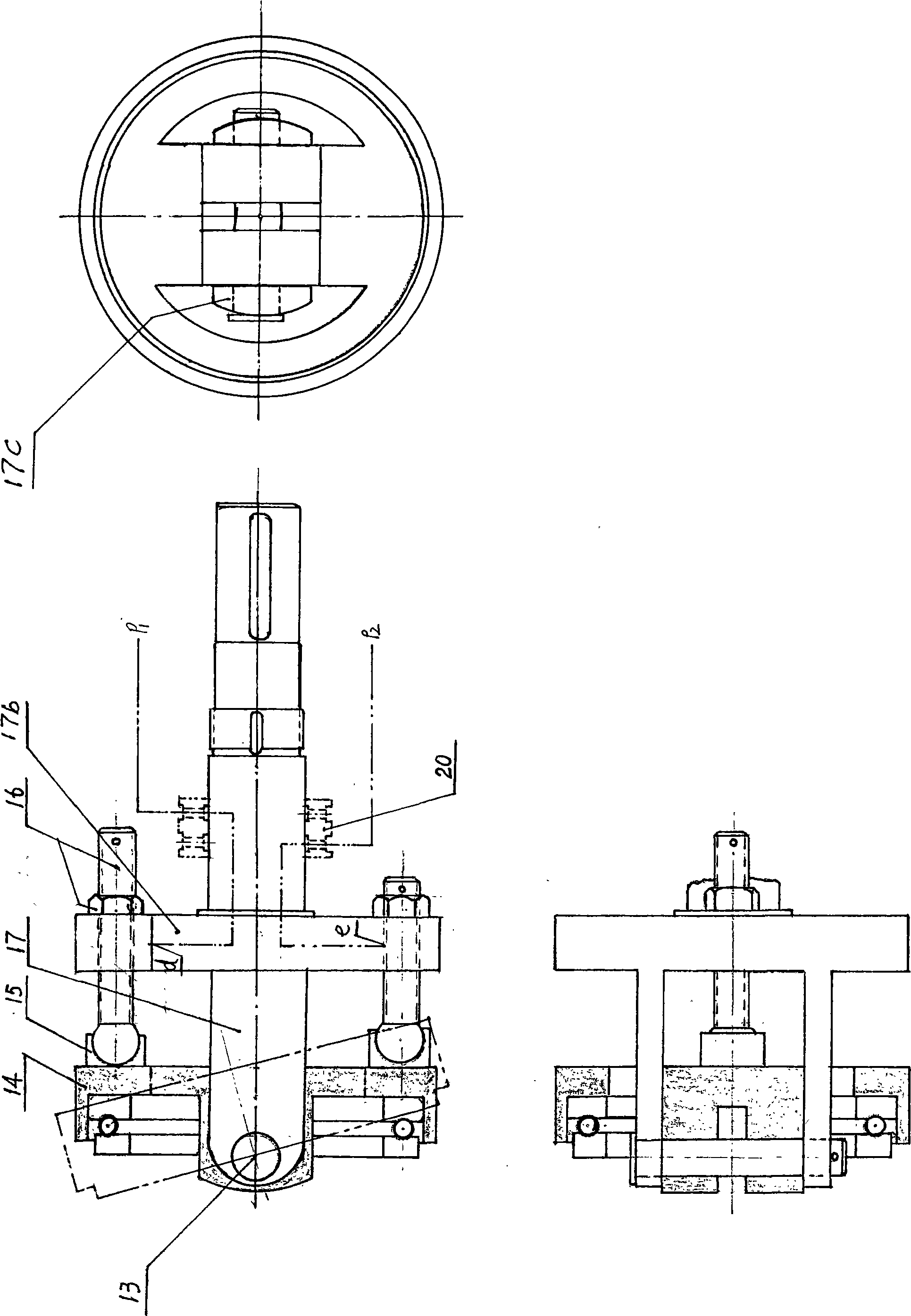

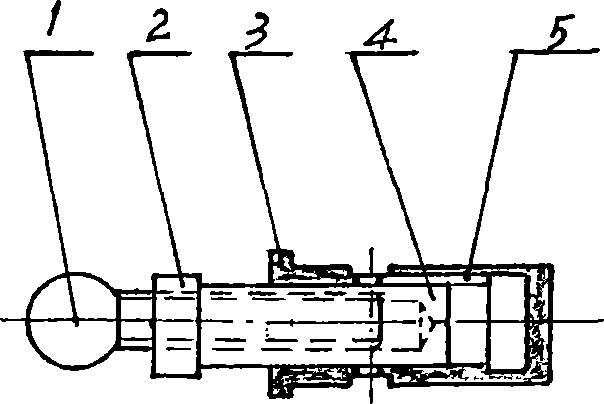

[0006] Aiming at the shortcomings of the above-mentioned swash plate axial piston pump, this paper newly designs a swash plate variable axial piston pump. figure 1 It is the general design drawing of the swash plate variable axial piston pump. The plunger pump consists of three parts: 1. The fixed valve plate part: composed of parts 1 to 7; 2. The fixed and non-rotating plunger cylinder part: composed of parts 8 to 12; 3. The swash plate Variable components: composed of parts 13-22. Wherein the part housing 19 is respectively screwed on the same axis with the above-mentioned three parts to form a whole.

[0007] Composed of parts 13-22 is the rotation variable part. Part 13 is a cylindrical pin, Part 14 is a variable swash plate, Part 15 is a copper-based alloy ball seat, Part 16 is a screw with a ball, Part 17 is a driving shaft, Part 18 is a cover plate for adjusting the window, and Part 19 is a connecting part 21 and the variable housing of piece 7, piece 20 is a gap sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com