Assembly node and construction method of prefabricated hollow beam and column

A construction method and hollow beam technology, which can be used in construction, building construction, etc., can solve the problems of time-consuming and material-consuming cast-in-place structures, poor connection rigidity between beams and columns of prefabricated structures, and poor adaptability to changes in the overall building. The effect of reducing concrete, shortening construction period and enriching architectural landscape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

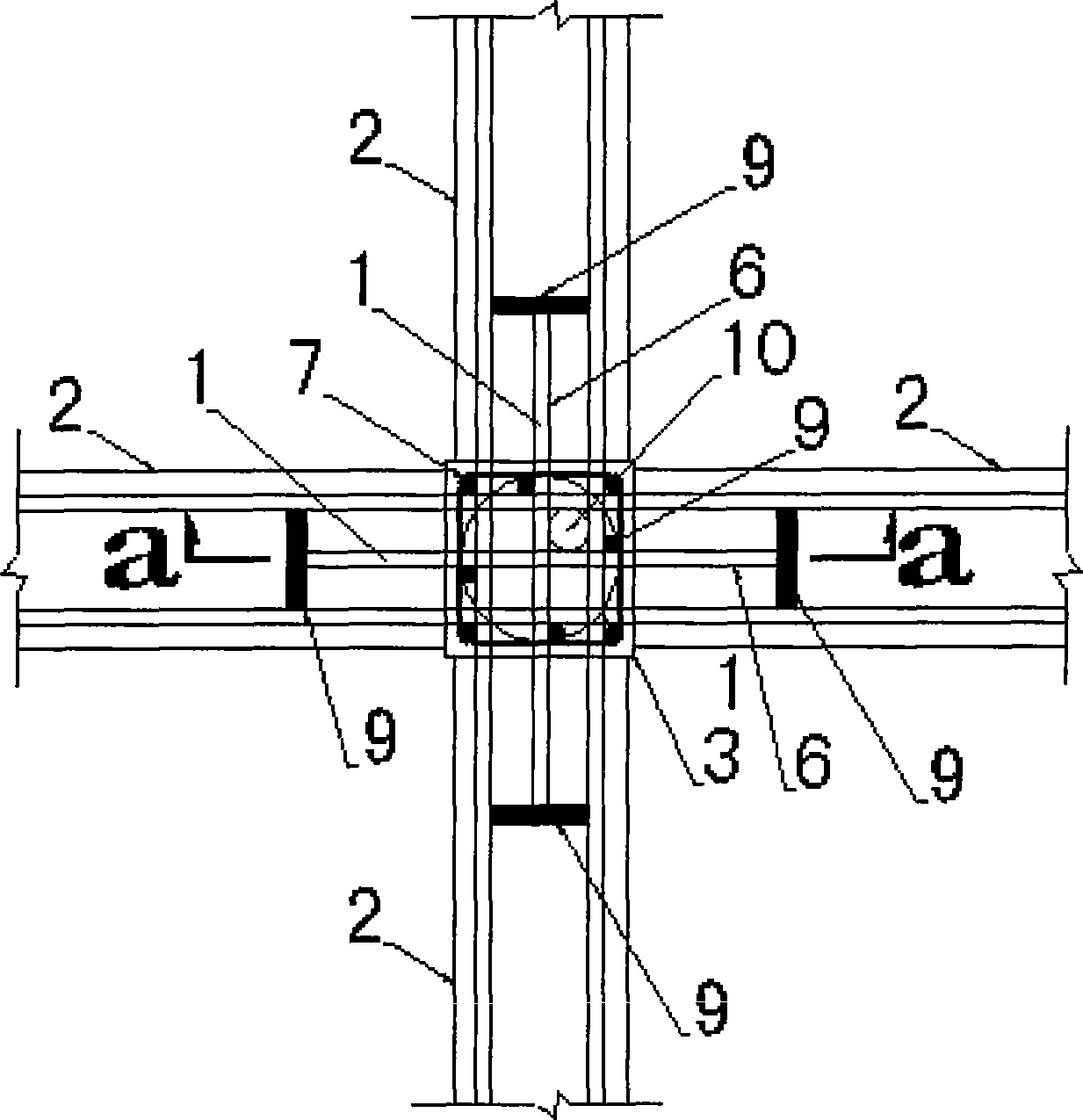

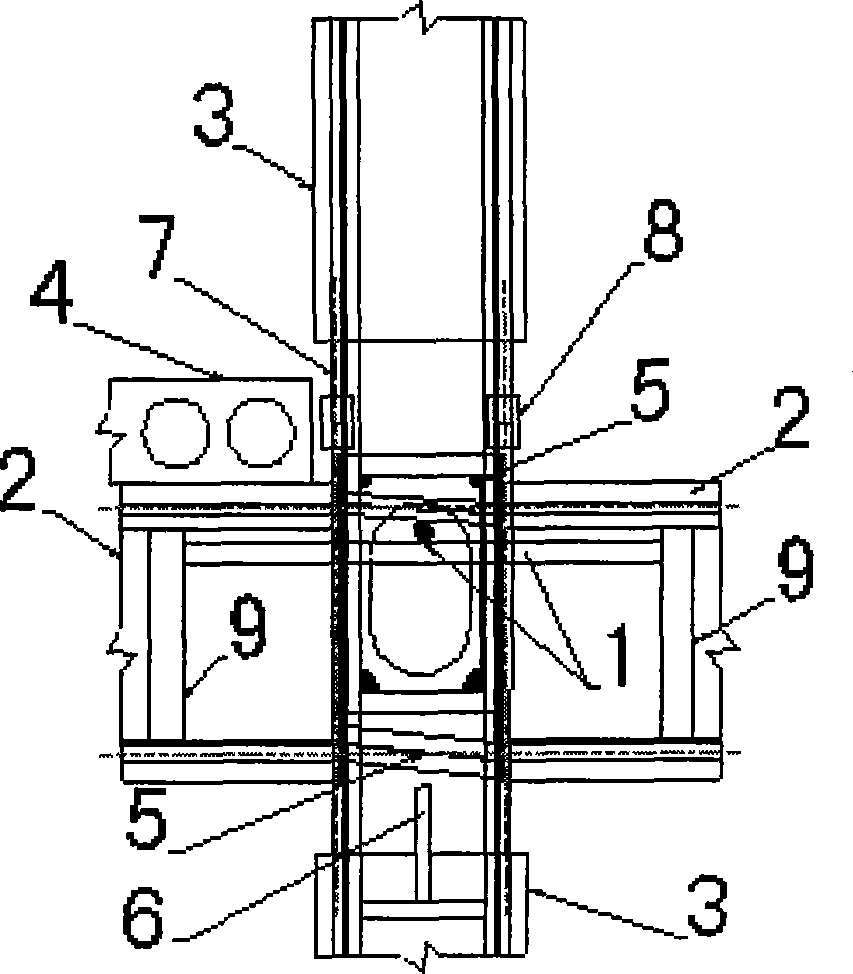

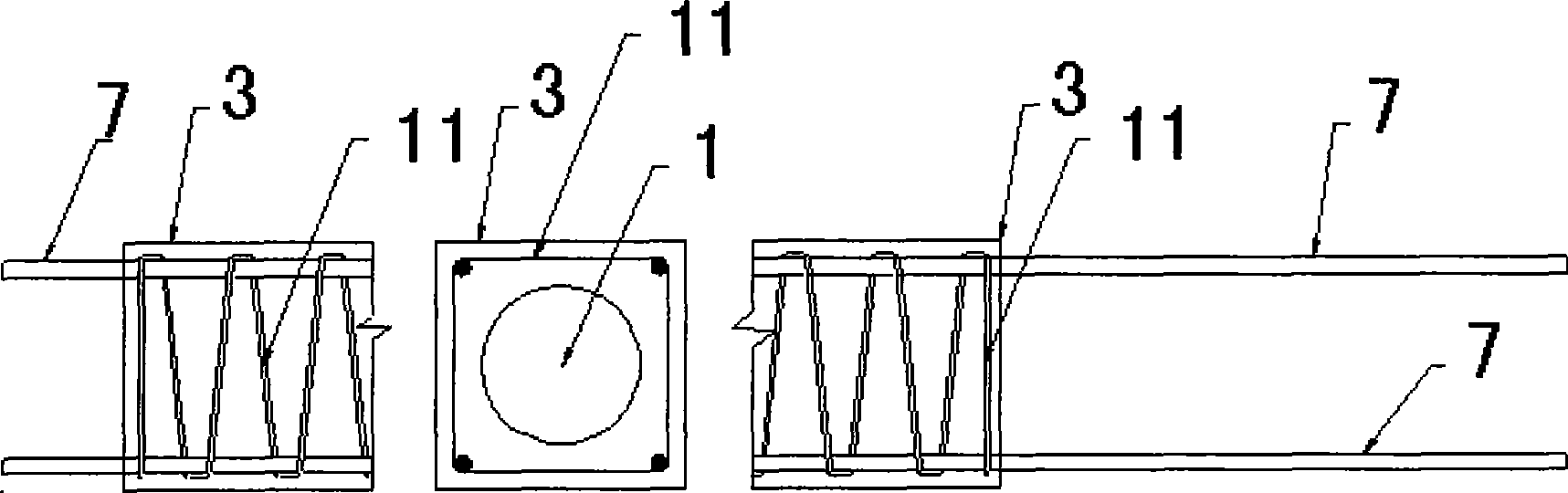

[0030] see figure 1 , figure 2 , a prefabricated hollow beam and column assembly node of the present invention is formed by prefabricated beams and columns through concrete casting, the prefabricated beam is a hollow beam 2, and the inner hole of the hollow beam 2 is embedded with a 3 through the heart lock 6.

[0031] The prefabricated hollow beam 2 and the prefabricated column 3 form a hexahedral node, the front, rear, left, and right sides of the node are respectively occupied by the hollow beam 2, and the upper and lower surfaces are respectively occupied by the upper and lower columns 3, in order to realize the joint cast-in-place Preferably the column 3 is a hollow column. When the connection between the hollow beam 2 and the column 3 is connected with a column 3, the column ribs 7 in the upper and lower columns 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com