Technology for manufacturing lock ring for wheeled engineering machinery wheel and shaping mold thereof

A technology for construction machinery and forming dies, applied in the direction of manufacturing tools, forging/pressing/hammering machinery, metal processing equipment, etc., can solve the problem that the shape and size of the workpiece cannot meet the requirements of the drawing design, the elasticity of the workpiece cannot meet the requirements of international standards, Product quality cannot be guaranteed and other problems, to achieve the effect of improving the elasticity of the lock ring, reducing the deformation resistance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

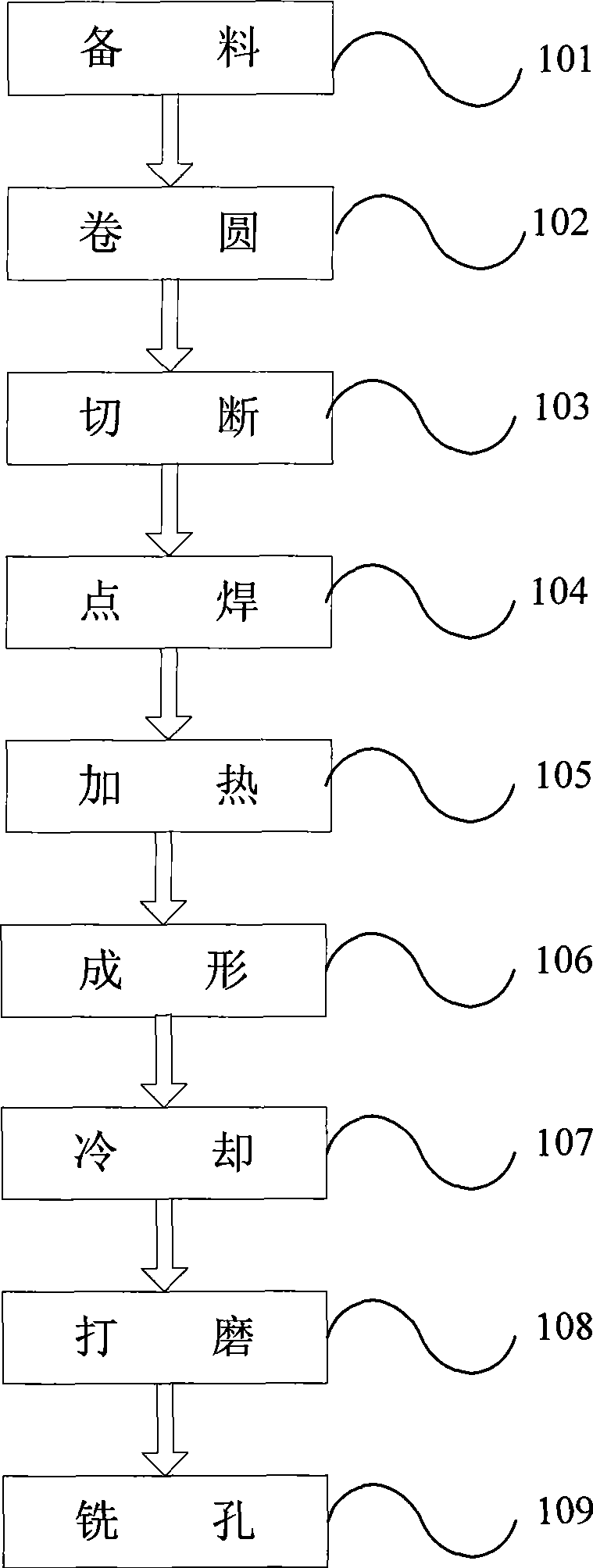

[0031] Such as figure 1 As shown, the embodiment of the wheel lock ring manufacturing process provided by the invention includes the following steps:

[0032] S101 Material preparation Rolling the steel billet into a long material with a prefabricated lock ring section structure shape;

[0033] S102 roll round Make the long material roll into a spiral coil material;

[0034] Utilize the existing coiling machine to make the long material roll into a helical coil material, the helical diameter of the helical coil material is substantially the same as that of the prefabricated lock ring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com