Manufacturing method for high brightness halogen lamp and high brightness halogen lamp thereof

A production method and halogen lamp technology, applied in the direction of luminous body, etc., can solve the problems of incompatibility of high-power lamps, weakened light brightness, and high energy consumption of halogen lamps, so as to overcome the cooling effect, improve light efficiency, and high light utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

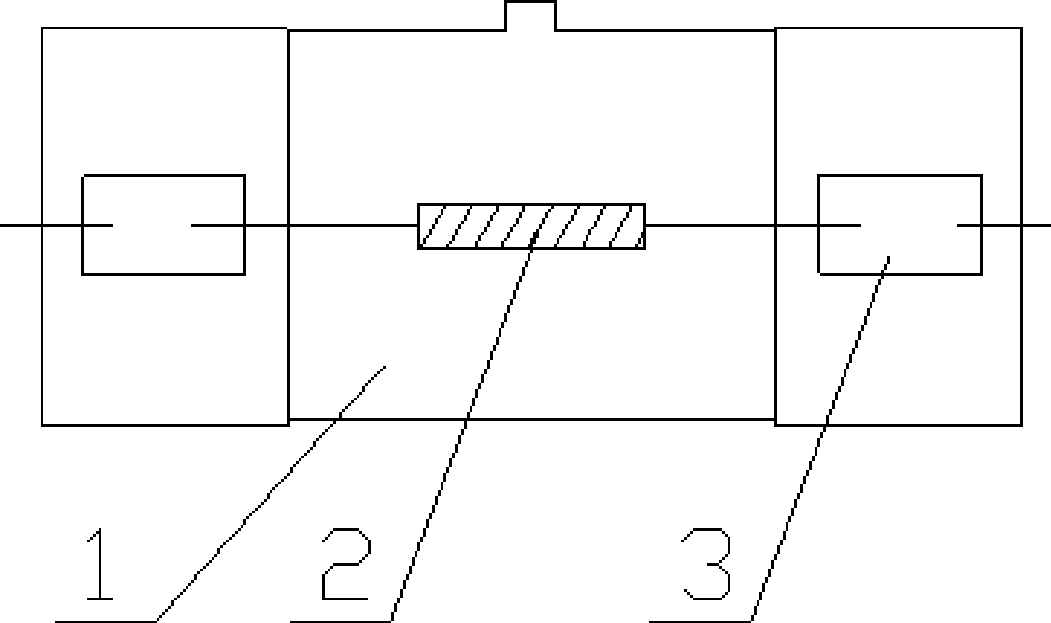

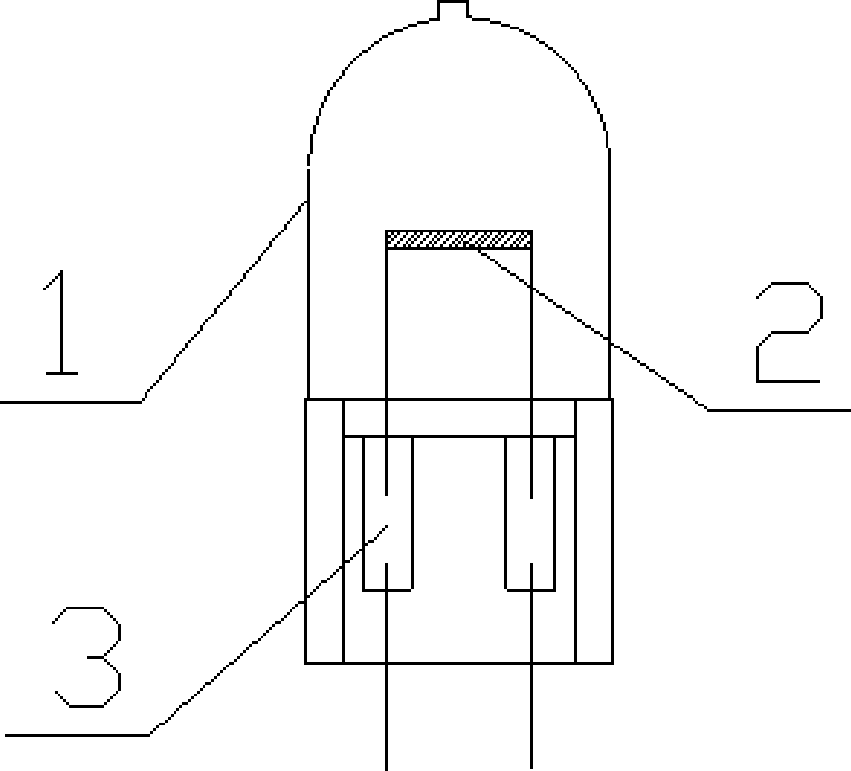

[0014] Embodiments of the present invention: taking a halogen lamp as an example, the structure is as follows figure 1 and figure 2 As shown, the bulb 1 is a quartz tube, and the wire feet at both ends of the filament 2 are respectively welded on the molybdenum sheet 3. The present invention winds the light-emitting area of the filament 2 into a filament with a triple helix structure, and the wire feet are of a double helix structure. Filament; the filament of the triple helix structure is made of a straight tungsten wire wound three times. Through a reasonable heat treatment process, it has good high temperature resistance and anti-sag performance during the entire life, and maintains the stability of various photoelectric parameters. The invention adopts The filament can increase the working temperature of the filament under the same power and improve the brightness of the present invention, and the filament of the triple helix structure does not need any form of support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com