Microlens array with small aberration

A microlens array and aberration technology, applied in the field of microlens arrays, can solve problems such as large aberrations, and achieve the effects of low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

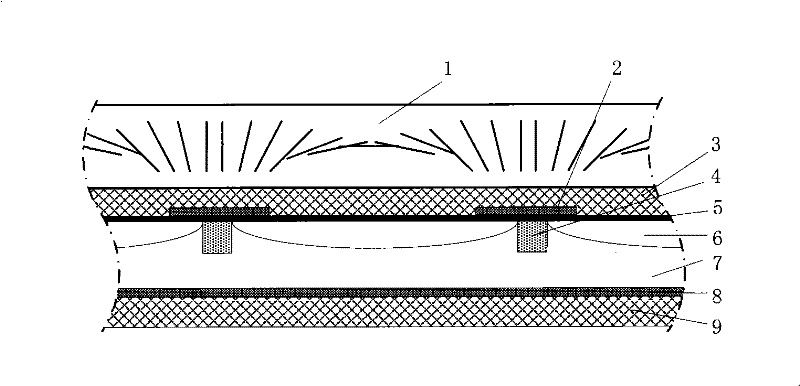

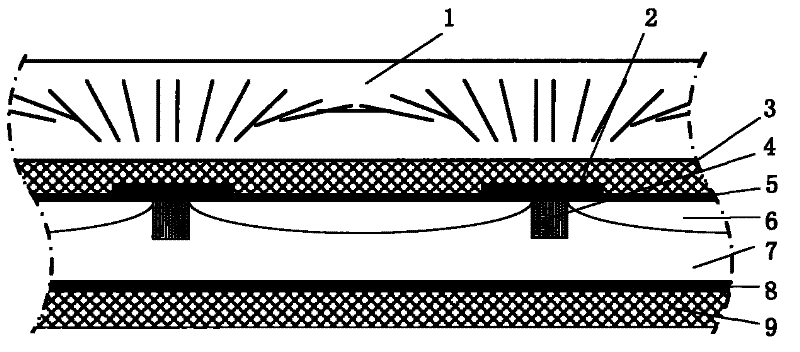

[0013] figure 1 Shown is a cross-sectional structure diagram of a preferred solution of the microlens array of the present invention, and the microlens array is mainly composed of a polymer lens 1 and a liquid lens. The polymer lens 1 has a fixed focal length, and can use UV-curable liquid crystal diacrylate monomers (the UV-curable LC diacrylate monomers) to form a film lens with a gradient refractive index (Reference 1: 'Flat polymeric microlens array', Optics Communications 261 (2006) 296-299), the liquid crystal molecules will deflect according to the strength of the applied electric field. In addition, because the liquid crystal molecules have birefringence characteristics, the refractive index of light is different at different deflection angles. When the applied electric field has a rotationally symmetrical structure , it can be formed with figure 1 Gradient-index thin-film lens shown in . The liquid lens has a variable focal length. The first substrate 3 is a transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com