Automatic clutch and use thereof

A technology of automatic clutch and driving disc, which is applied in the field of mechanical transmission parts, can solve the problems of small transmission torque, fast wear, automatic separation of the driving disc and driven disc, etc., and achieve the effect of ensuring smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

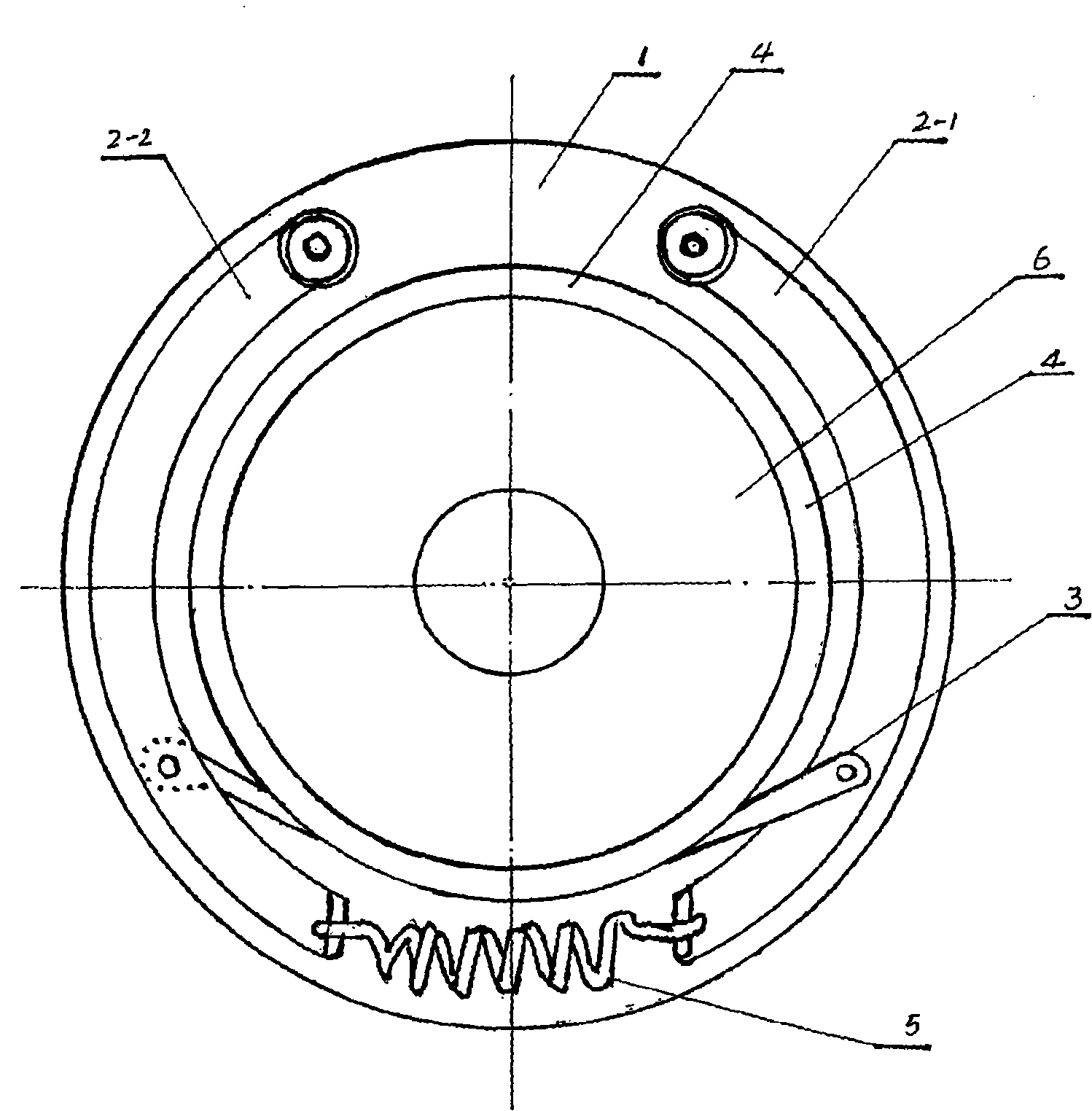

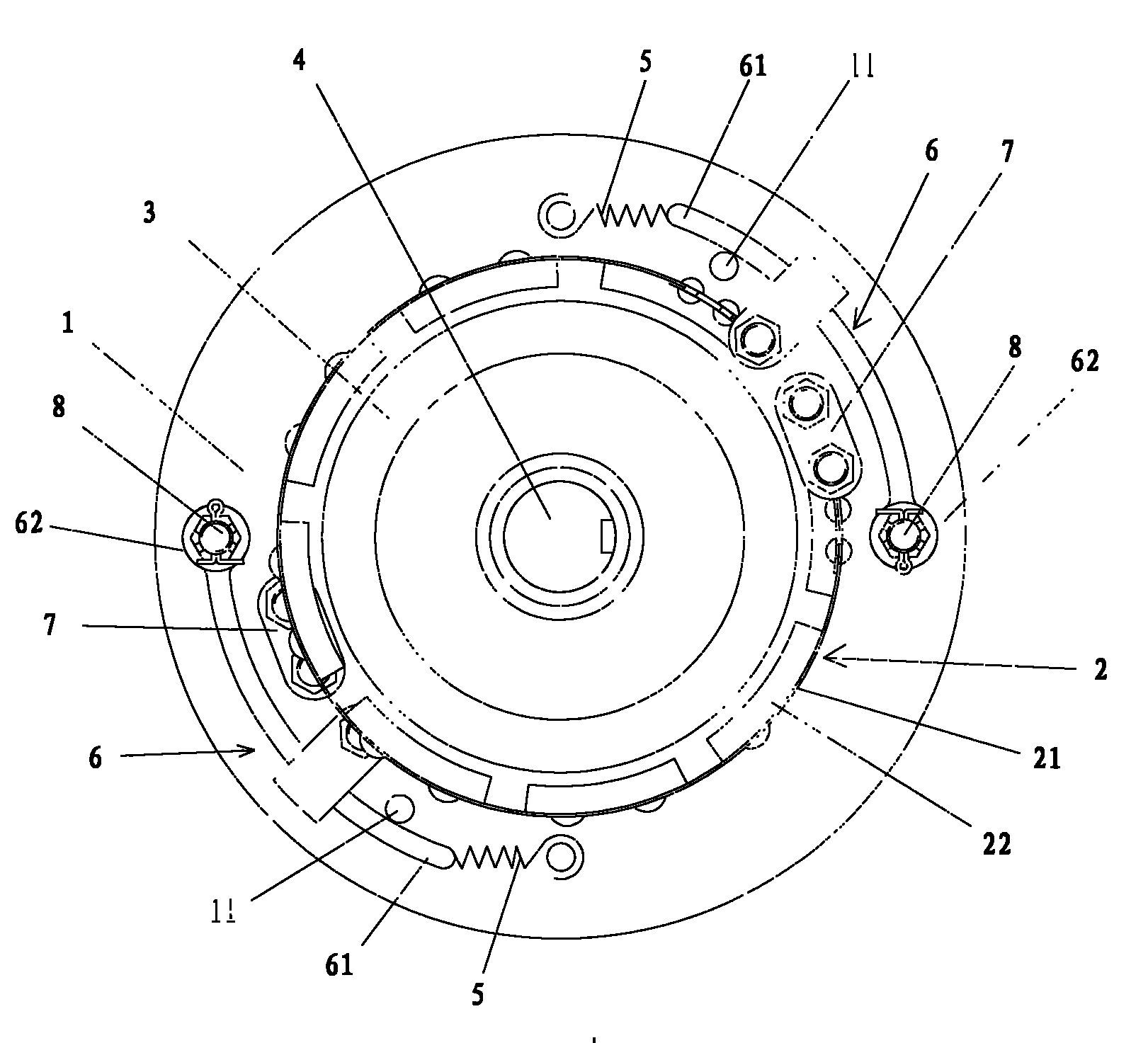

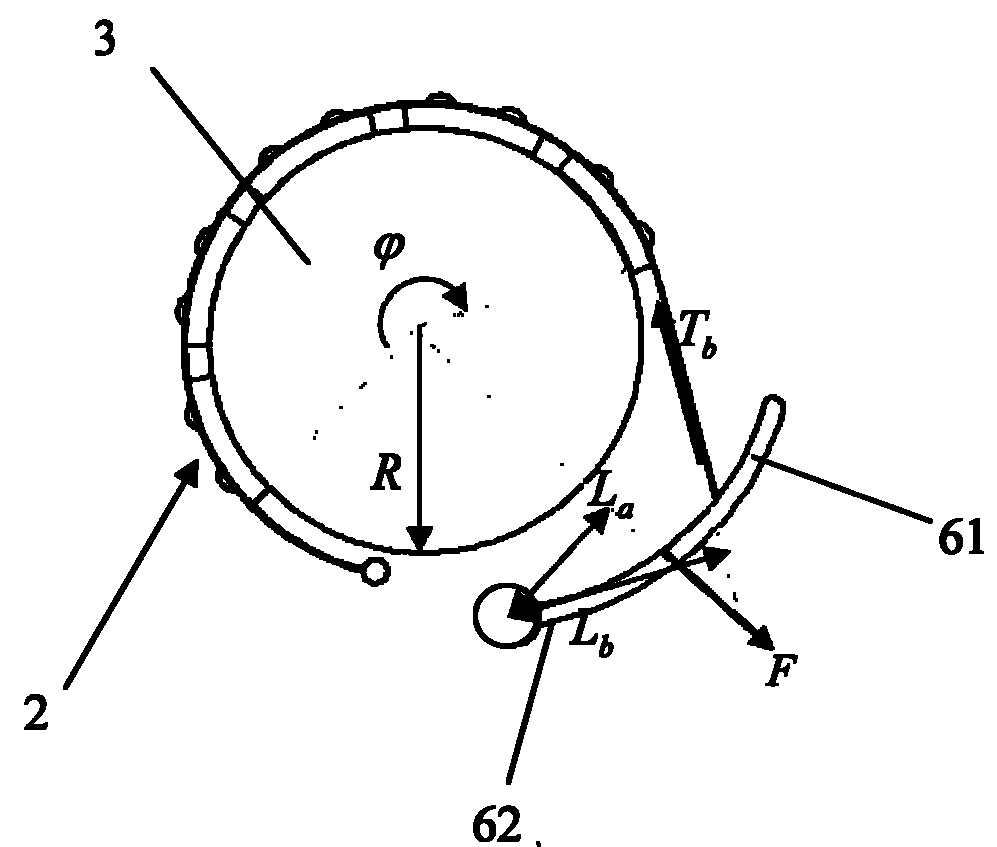

[0032] Such as Figure 2 ~ Figure 4 As shown, the automatic clutch of the present invention includes a driving disc 1, a driven disc 3, and a friction element 2. Two swing arms 6 are symmetrically arranged on the center of the driving disc 1, and each swing arm 6 is respectively provided with a fixed end 62 and a swinging arm 6. end 61, the fixed end 62 of each swing arm 6 is movably connected with the drive disc 1 in a rotatable manner through the rotating shaft 8 fixed on the drive disc 1, and the swing end 61 of each swing arm 6 can be connected by the spring 5 and other elastic parts are connected with the driving disc 1, one end of the friction element 2 can be fixedly connected with the driving disc through a fixed member such as a fixed shaft 7, and the other end of the friction element 2 surrounds the driven disc 3 for about 240 to 360 degrees (or 180~360 degrees) and then connected with the position close to the swing end 61 of the swing arm 6.

[0033] The above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com