Electric device for cam lock

An electric device and cam lock technology, which is applied in the field of combination locks, can solve the problems of high power consumption of electromagnets, stuck screws, and stress concentration, etc., and achieves easy processing and installation, tight electromechanical integration, and reduced stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

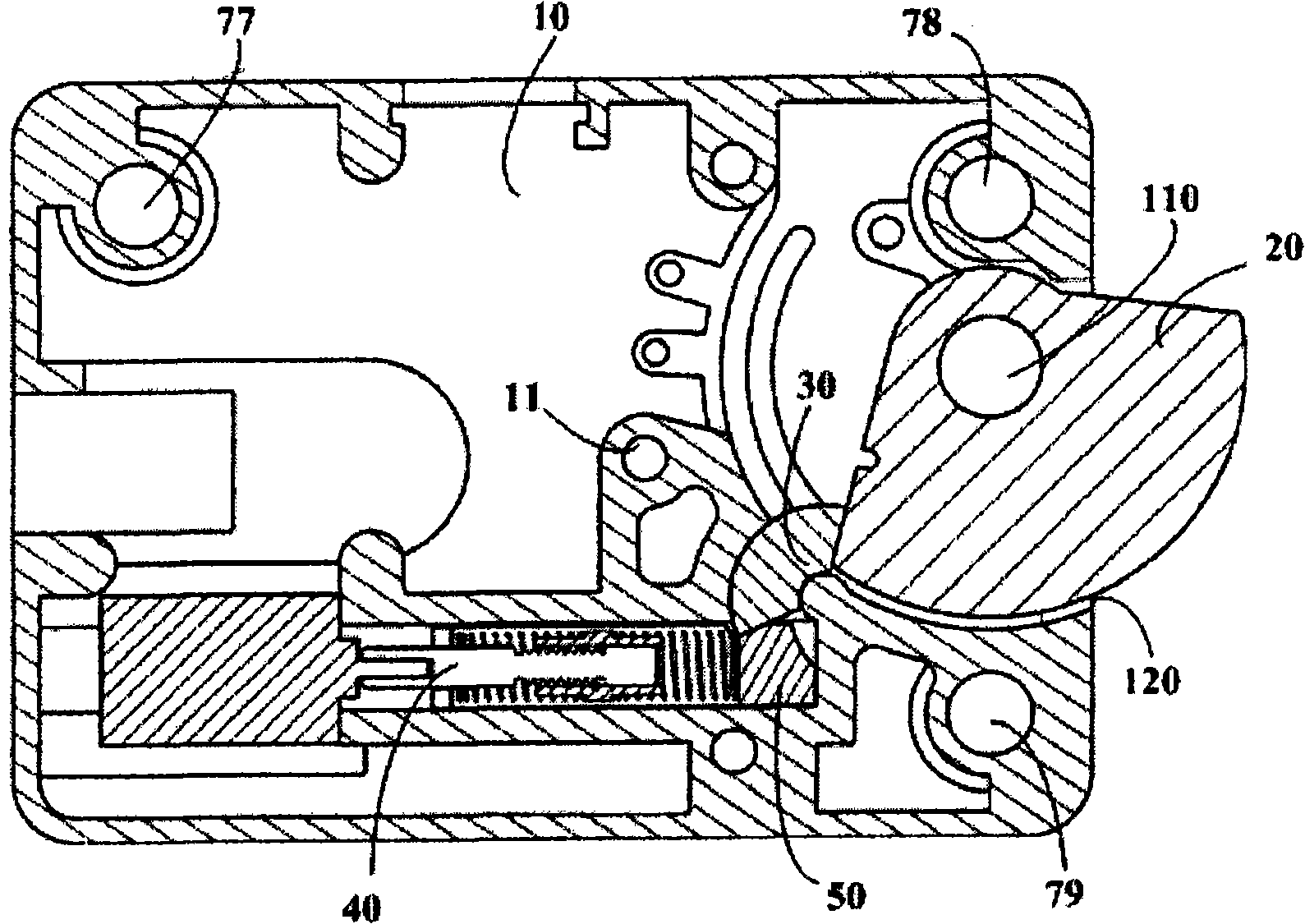

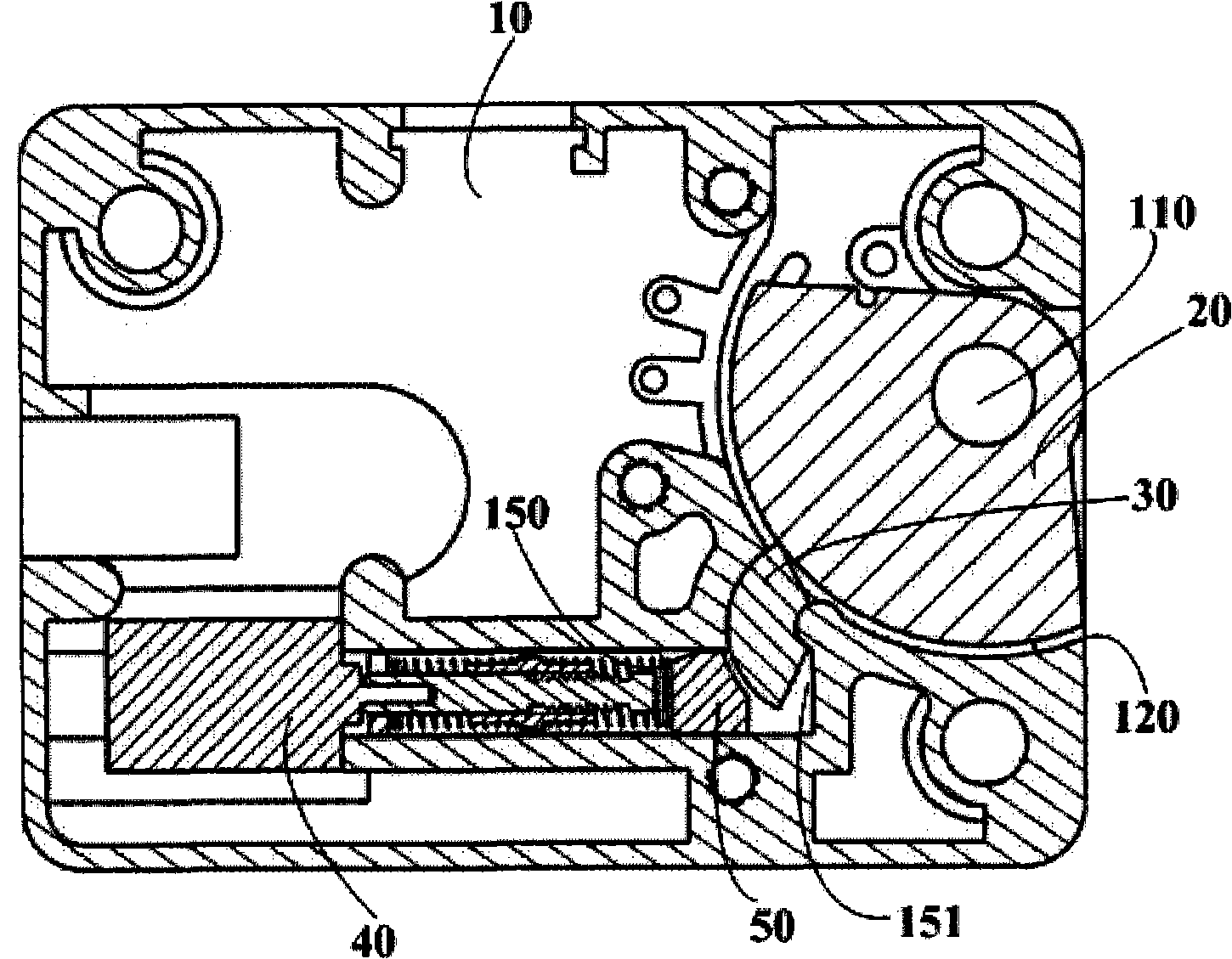

[0045] From figure 1 and figure 2 It can be seen that the fan-shaped dead bolt 20 is loaded into the shaft 110 in the lock box through the shaft hole 24 thereon, and can rotate around the shaft within a range of about 90 degrees. The height of the annular cylinder 31 of the block 30 and the height of the first slide groove 130 are substantially close to the plane thickness of the lock tongue 20, and the movement thereof is also carried out in the same plane.

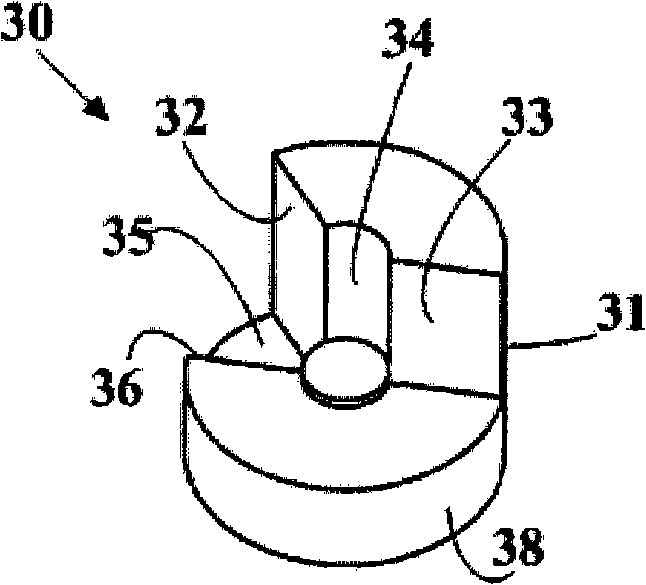

[0046] combine image 3 and Figure 4 , when assembling, the dead bolt 20 is first packed, and then the annular cylinder 31 of the block 30 is packed into the first chute 130 in the lock box, which is composed of a semi-cylindrical surface 131 and It is composed of an inner cylindrical wall surface 132 opposite to it, and the distance between the two is just the ring width of the annular cylinder 31 of the stopper 30, but the sliding fit relationship between them needs to be ensured. After the block 30 is loaded, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com