Tamping apparatus for railroad switch

A technology of turnout and box, which is applied in the field of railway line maintenance equipment - tamping device, which can solve the problem that a single pick cannot be inserted down, and achieve the effect of improving track stability, reducing impact and ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

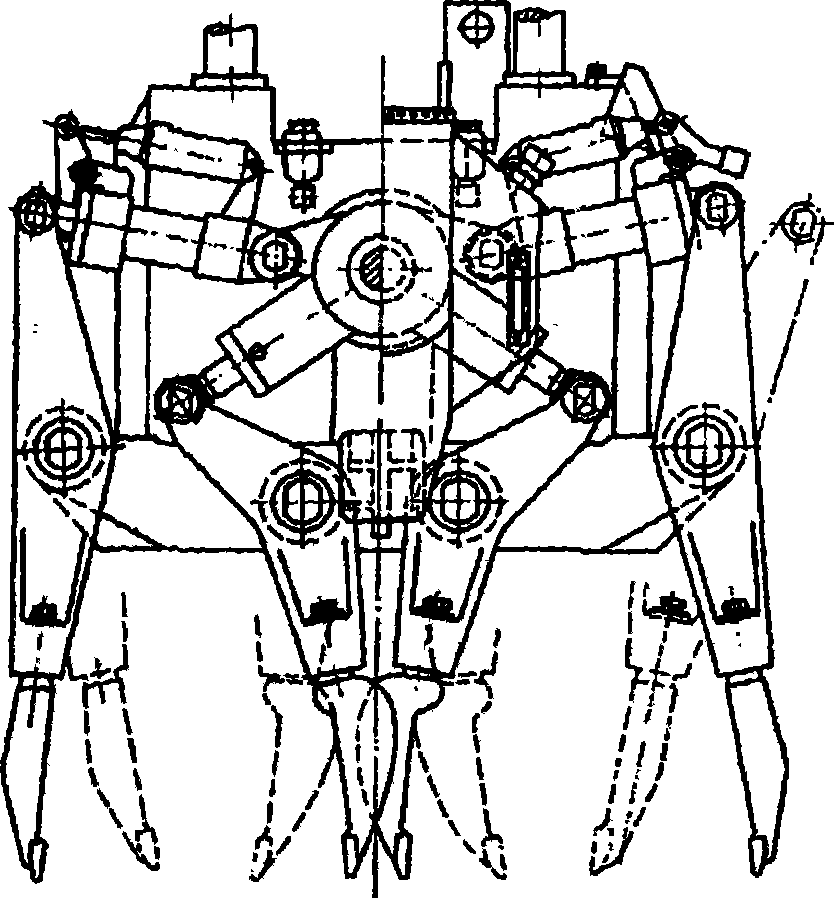

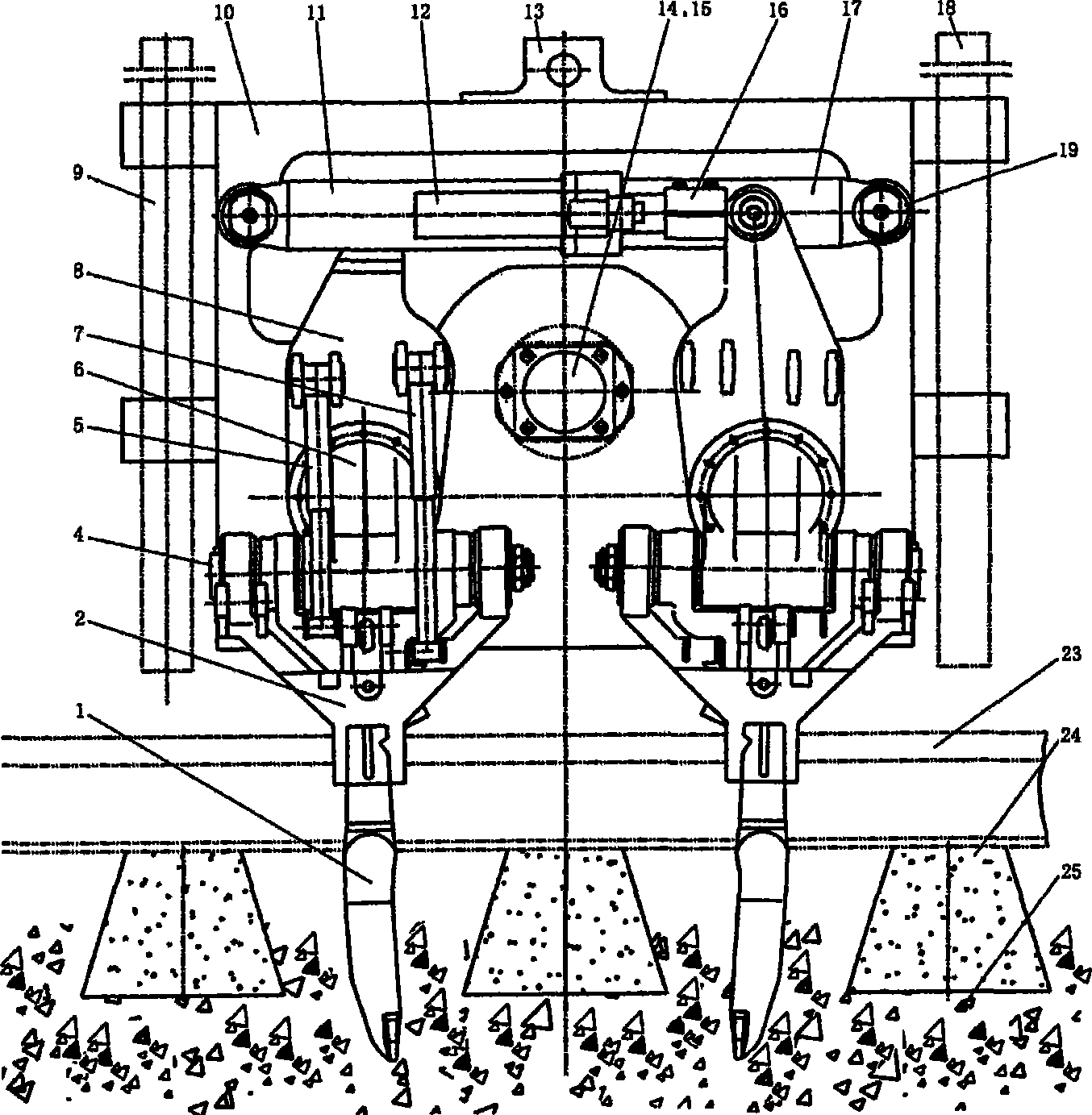

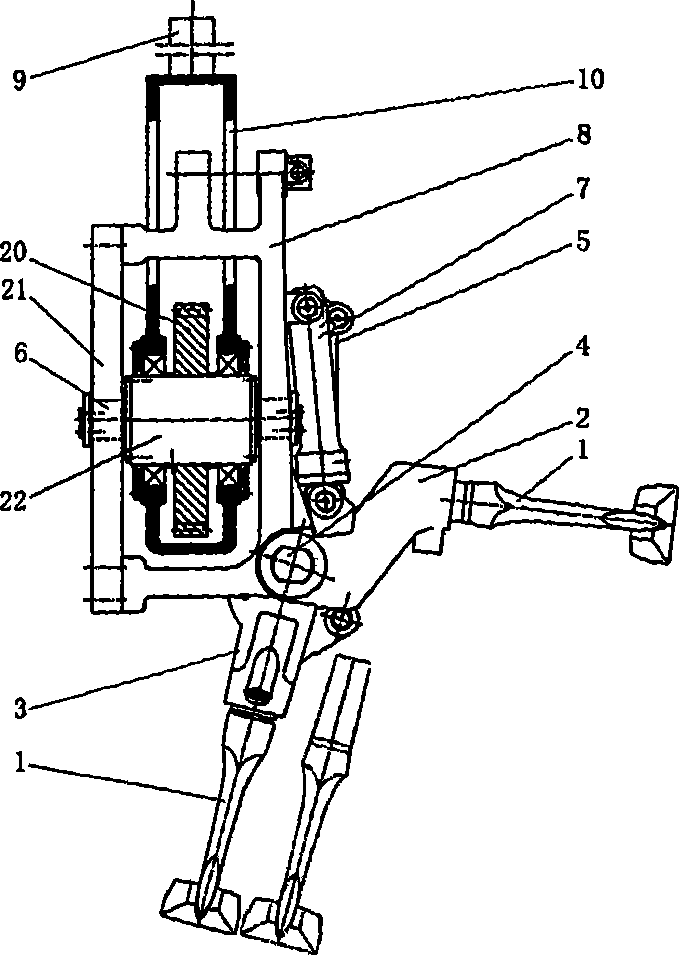

[0016] figure 2 , image 3 Among them, this embodiment includes a set of gear transmission mechanism 20 and two tamping arms 8 for tamping a single sleeper, which are symmetrically arranged laterally along the steel rail 23 with respect to the vertical symmetry line in the middle. The inner and outer two tamping picks 1 on the same side keep a certain distance to meet the clamping width. The oil motor 14 is respectively connected to the eccentric sleeve 22 through the two driven gears of the gear transmission mechanism 20. The eccentric sleeve 22 has a vibrating shaft 6, and the middle part of the tamping arm 8 is fixed on the outside of the vibrating shaft and is linked with the vibrating shaft. The tamping arms are connected with respective independent clamping oil cylinders and tamping picks 1 . The left arm clamping oil cylinder 17 is equipped with on the tamping arm 8 top of the left side, and the right arm clamping oil cylinder 11 is equipped with on the tamping arm 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com