Cartridge of a knitting machine

A technology of looms and knitting needles, applied in knitting, weft knitting, warp knitting, etc., can solve problems such as damage, and achieve the effect of speeding up repairs and repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

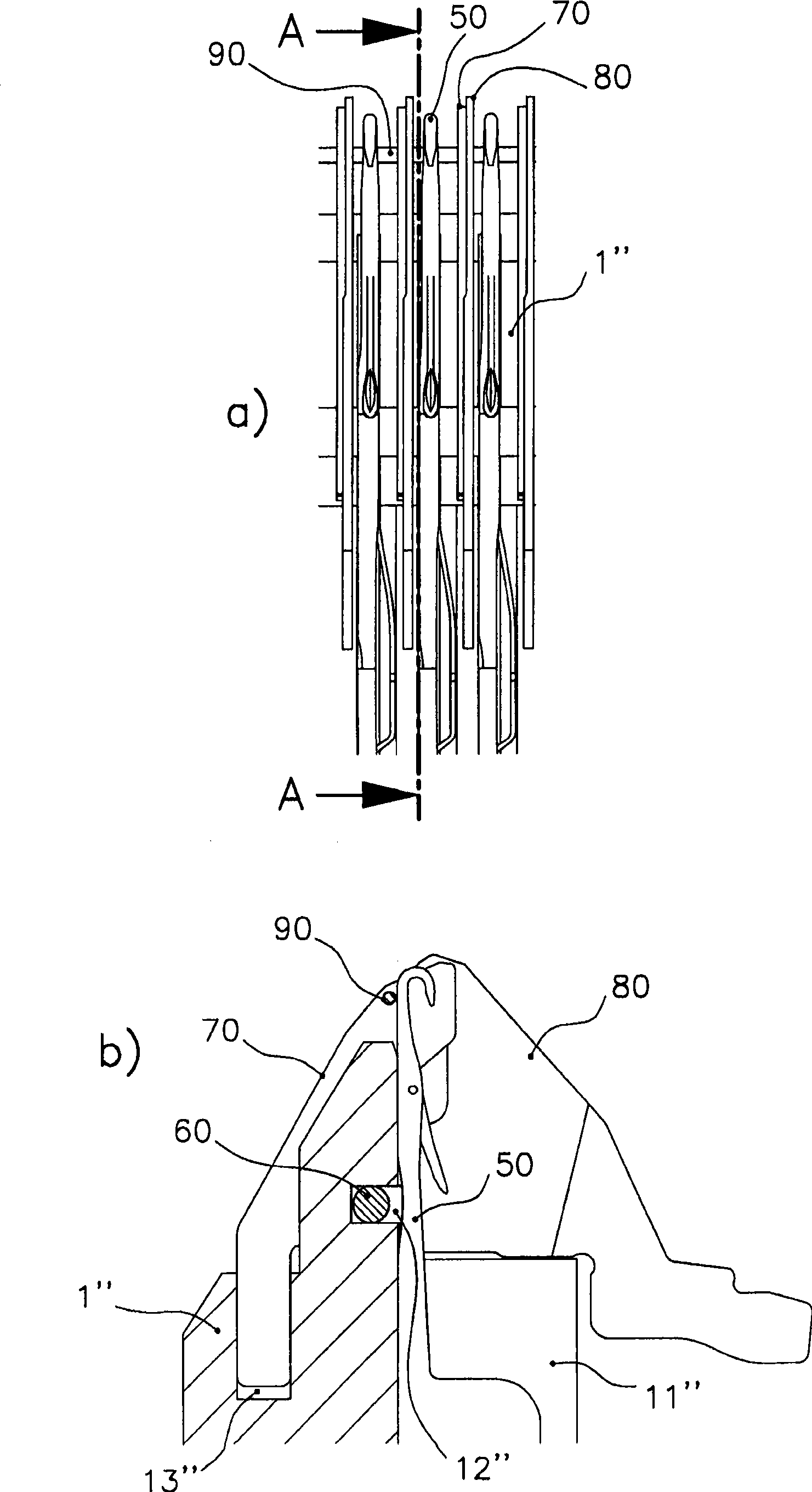

[0040] figure 2 a is a cutout of the knitting area of the needle bed 1 when looking down at the needle bed 1, in which a box 2 designed according to the first solution of the present invention is arranged, and the box 2 contains elements required for knitting.

[0041] figure 2 b shows the figure 2 The area where the box 2 is placed in the needle bed 1 shown by the section line B-B in a.

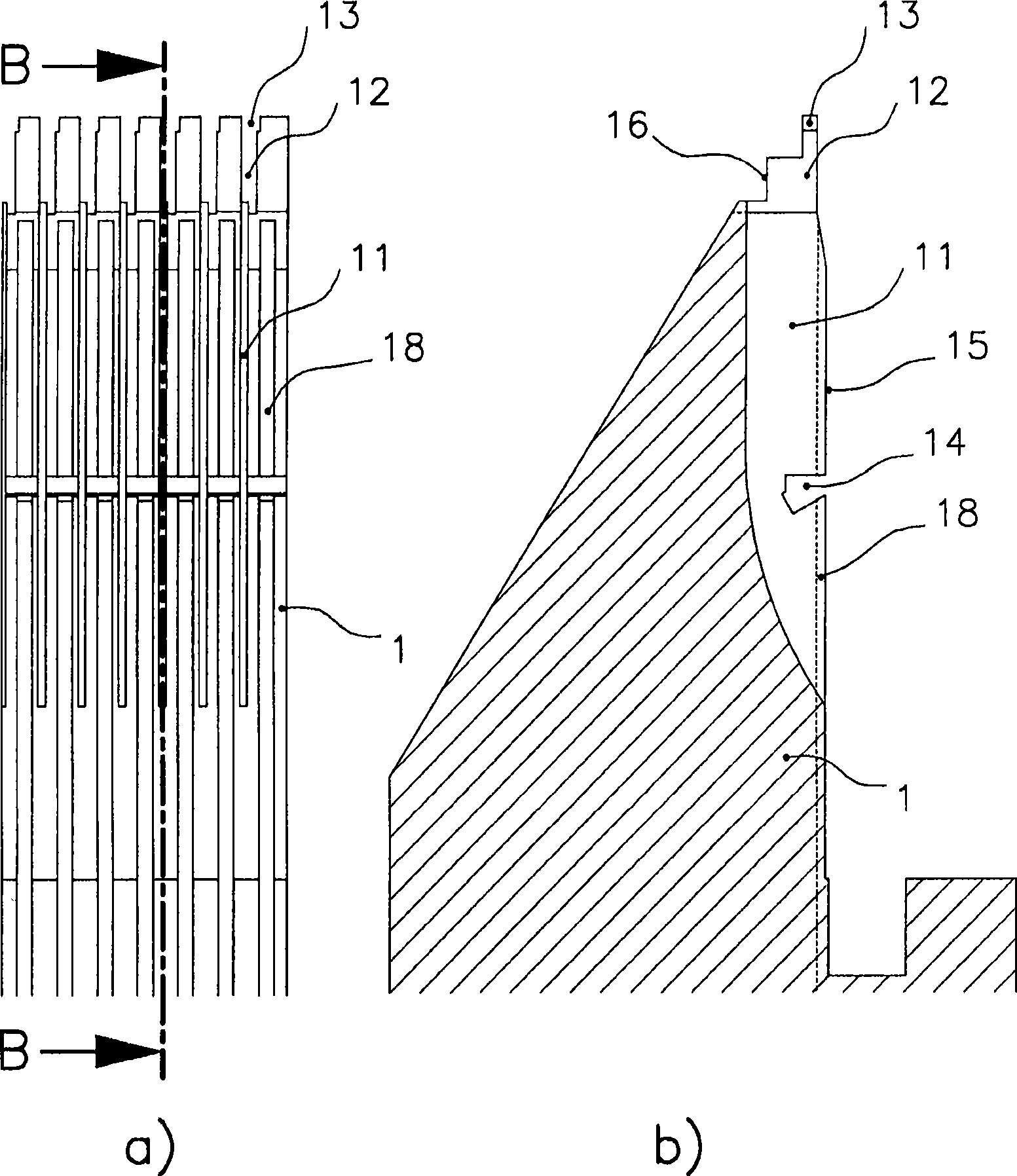

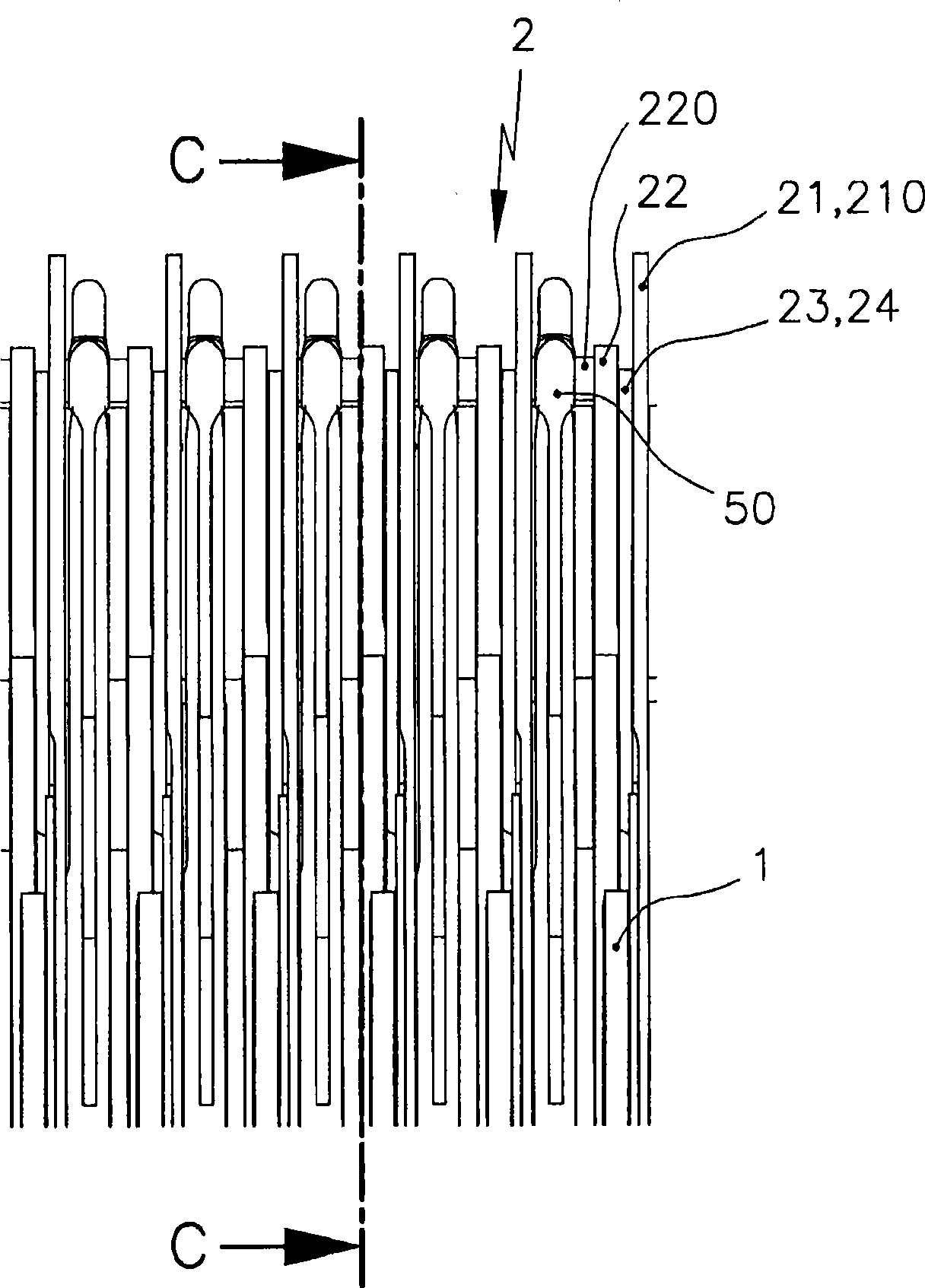

[0042] The needle bed 1 contains grooves 18 for receiving knitting needles 50 which, although only visible in the region shown, extend across the entire width of the needle bed perpendicularly to the longitudinal sides of the needle bed outside the stitch forming region. The groove 11 is arranged parallel to the groove 18 in the region of the stitching. Box 2 ( image 3 , Figure 4 ) is fixed in the slot 11 in the position of its associated needle 50 . The groove 12 extending perpendicular to the plane of the needle bed, that is to say perpendicular to the plane along the longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com