Technique of preparing high-purity bentazone raw pesticide

A preparation process and technology, which is applied in the field of improving the preparation process of high-purity bentazone technical, can solve the problems of dust pollution and low purity, and achieve the effect of easy crystallization and drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

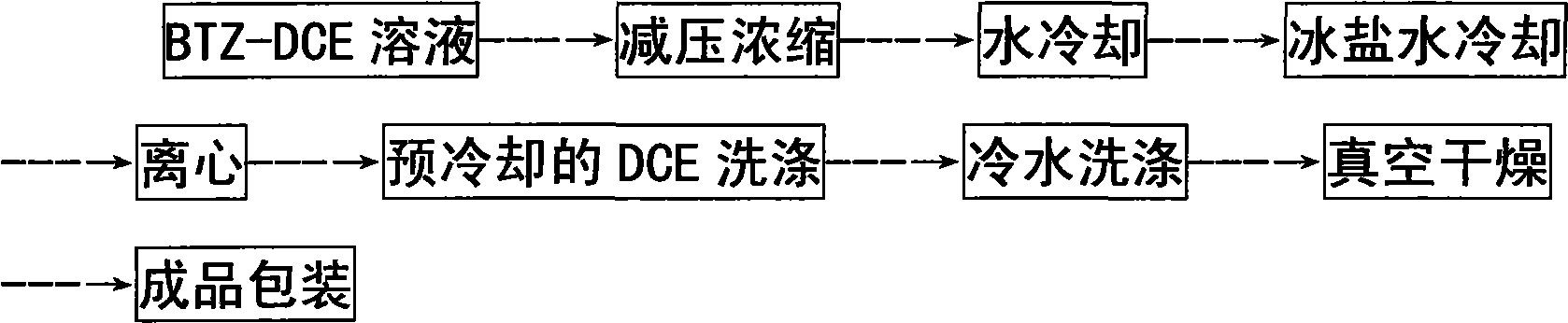

[0017] As can be seen from the accompanying drawings, a kind of preparation technology of bentazone former medicine, its process step is as follows: A, in there-necked bottle, add the washed bentazone 75 grams, dichloroethane 700 grams to form BTZ-DCE solution 775 grams (about 621 liters); B. Place the three-neck bottle in hot water and slowly heat up to 60°C, and steam the DCE under reduced pressure;

[0018] C. After cooling with brine in a glass condenser, collect about 440 milliliters of fractions in a 1000 milliliter round bottom flask and stop;

[0019] D. Slowly cool to 35°C in tap water, then cool to -5°C with ice-salt water, and centrifuge;

[0020] E. Wash with a small amount of cold DCE and water, and dry in a vacuum oven to obtain a product (purity ≥ 97%).

Embodiment 2

[0022] As can be seen from the accompanying drawings, a kind of preparation technology of bentazone former medicine, its process step is as follows: A, in there-necked bottle, add the washed bentazone 75 grams, dichloroethane 700 grams to form BTZ-DCE solution 775 grams (about 621 liters); B. Place the three-neck bottle in hot water and slowly heat up to 60°C, and steam the DCE under reduced pressure;

[0023] C. After cooling with brine in a glass condenser, collect about 440 milliliters of fractions in a 1000 milliliter round bottom flask and stop;

[0024] D. Slowly cool in well water to 35°C, then cool to -5°C with ice-salt water, and centrifuge;

[0025] E. Wash with a small amount of cold DCE and water, and dry in a vacuum oven to obtain a product (purity ≥ 97%).

Embodiment 3

[0027] As can be seen from the accompanying drawings, a kind of preparation technology of bentazone former medicine, its process step is as follows: A, in there-necked bottle, add the washed bentazone 75 grams, dichloroethane 700 grams to form BTZ-DCE solution 775 grams (about 621 liters); B. Place the three-neck bottle in hot water and slowly heat up to 60°C, and steam the DCE under reduced pressure;

[0028] C. After cooling with brine in a glass condenser, collect about 440 milliliters of fractions in a 1000 milliliter round bottom flask and stop;

[0029] D. Slowly cool in mineral water to 35°C, then cool to -5°C with ice salt water, and centrifuge;

[0030] E. Wash with a small amount of cold DCE and water, and dry in a vacuum oven to obtain a product (purity ≥ 97%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com