Air door of plasma cutting machine dust-removing apparatus and partition dust-removing apparatus

A technology of a plasma cutting machine and a dust removal device, which is applied in the directions of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high cost and complicated damper structure, achieve reliable and stable performance, save high costs, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

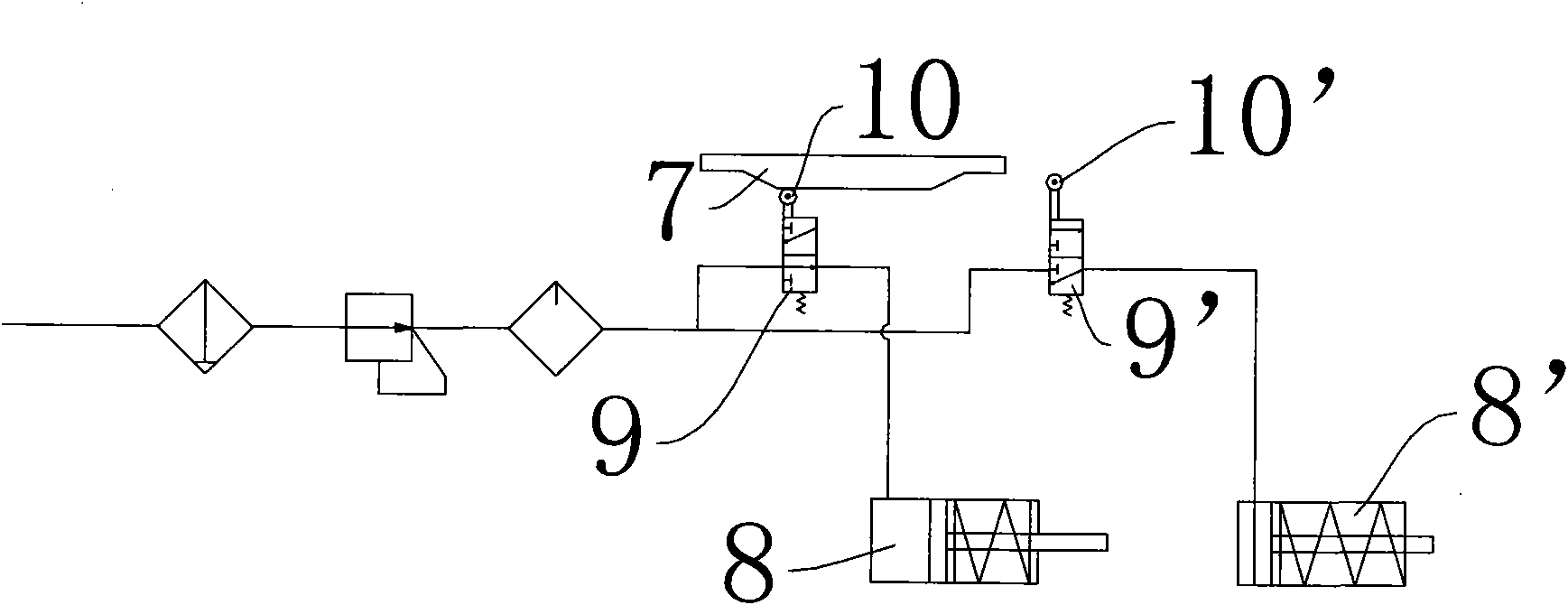

[0018] see Image 6 , the comprehensive dedusting device of the plasma cutting machine, comprises machine base 17, the horizontal vehicle frame 22 that moves linearly on machine base 17, the multifunctional cutting torch shield 20 that is contained on the cutting torch, connects multifunctional cutting torch shield 20 and dust removal The flexible air duct 11 of the device 24. The stand 25 mounted on the support 17 is placed on the workpiece 32 on the stand 25 . A plurality of dampers 14 installed on one side of the support 17, a square air duct (exhaust duct) 19 connecting the damper 14 and the dust removal device 24; to valve 9.

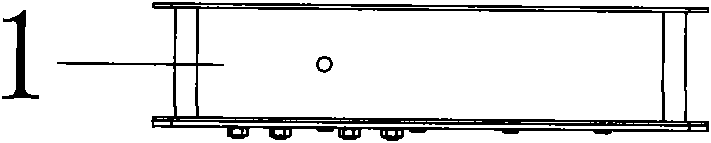

[0019] Such as Figure 4 , one end of the air duct 1 in each air door is connected with the frame 17 side of the plasma cutting machine (inner cutting area of the frame); connected.

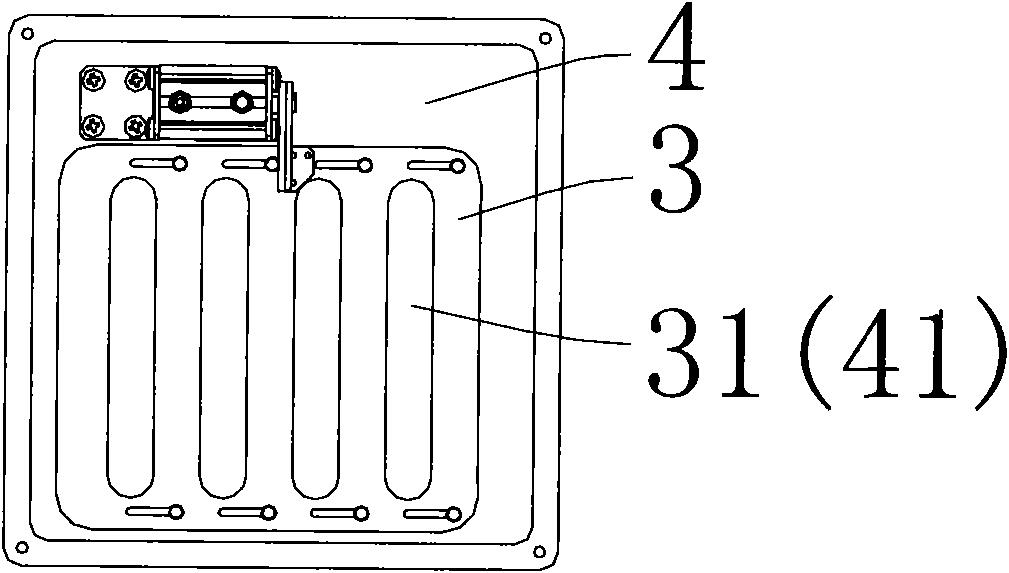

[0020] Each damper has the same structure, including the air duct 1, and one end of the air duct is connected with a fixed grid plate 4 with a plurality of fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com