Ultralarge-diameter single pile foundation level static load device and test method

A single-pile foundation and horizontal static load technology, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problem of not considering the cost of ship machinery, etc., and achieve low input costs, rapid soil penetration, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

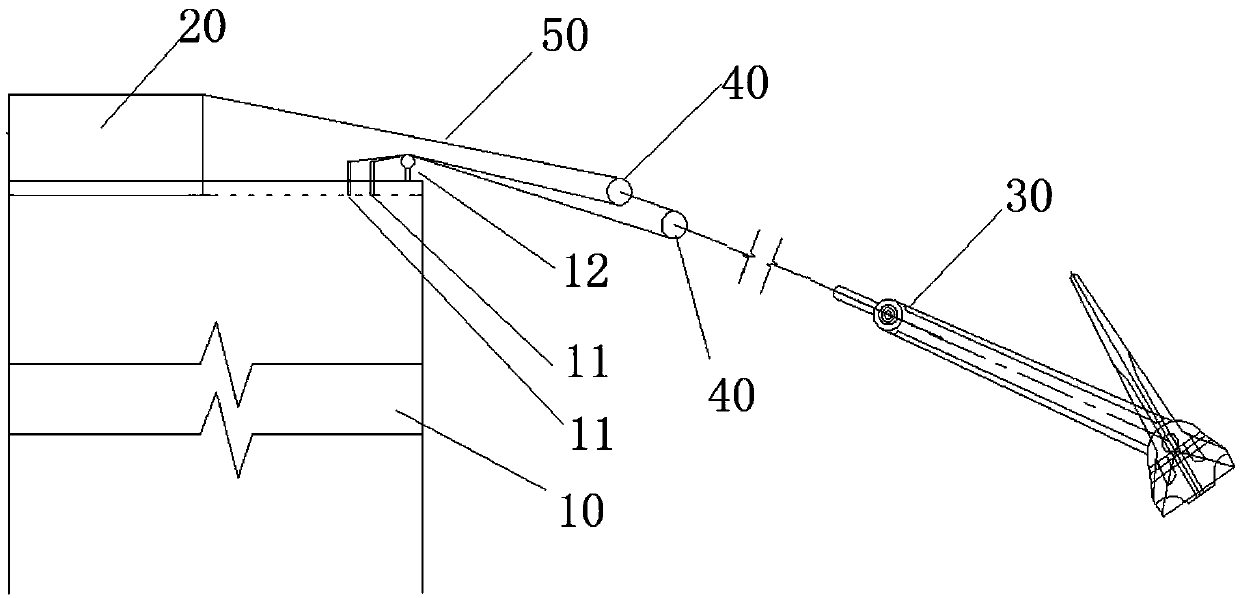

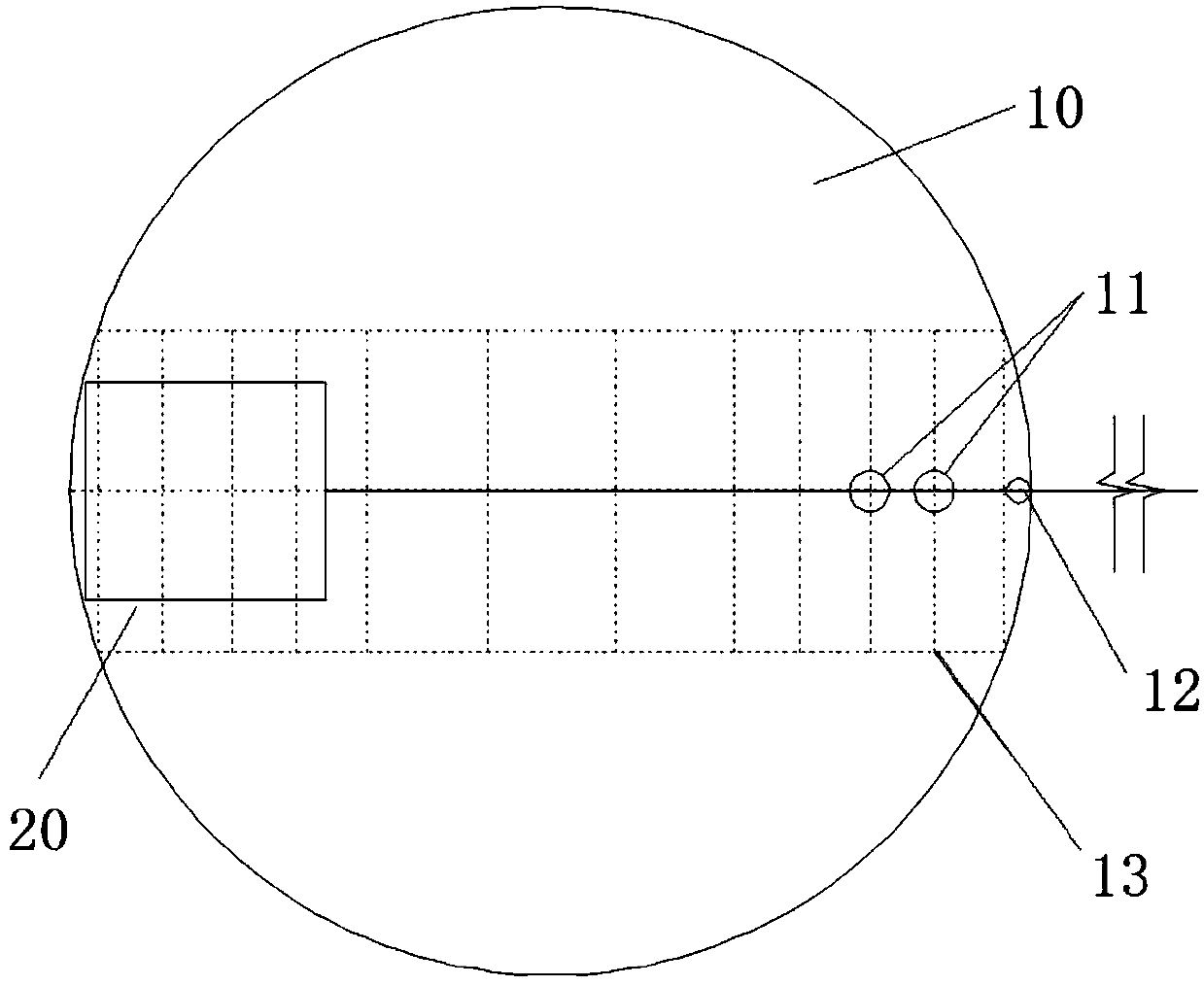

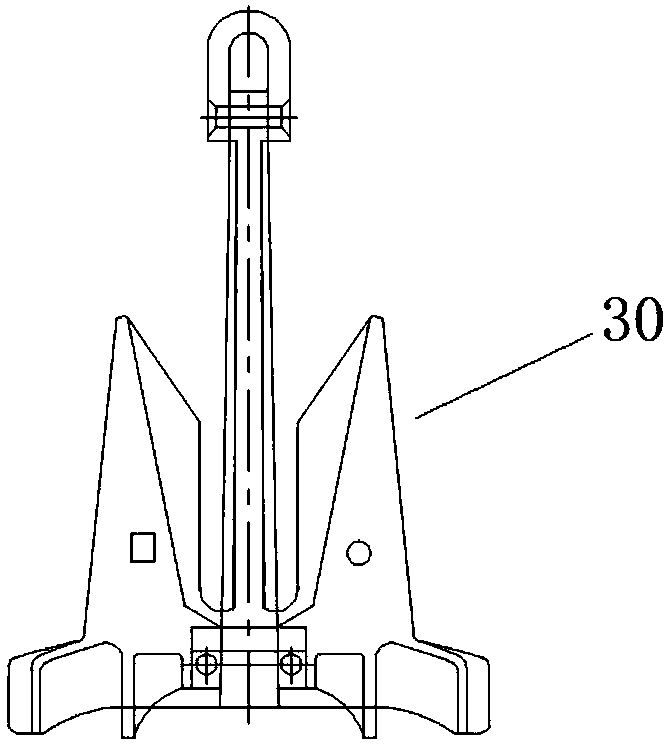

[0024] Such as Figure 1 to Figure 2 As shown, the super-large-diameter single-pile foundation horizontal static load device in this embodiment includes a tension mechanism 20 arranged on the pile body 10, a gripping mechanism 30 arranged on the outside of the pile body 10 and thrown to the seabed, a pulley assembly and a multi-section anchor cable 50. The anchor cable 50 includes a first anchor cable, a middle anchor cable and a final anchor cable, one end of the first anchor cable is fixedly connected to the tension mechanism 20, and the other end is fixedly connected to the pulley assembly; One end of the terminal anchor cable is fixedly connected to the pulley assembly, and the other end is fixedly connected to the gripping mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com