Method for improving continuous casting plate blank central segregation based on growth morphology analysis of coagulating shell

A technology for solidifying shells and continuous casting slabs, which is applied to the improvement of continuous casting slab center segregation and the field of slab continuous casting solidification process. Effect of center segregation and avoiding excessive segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

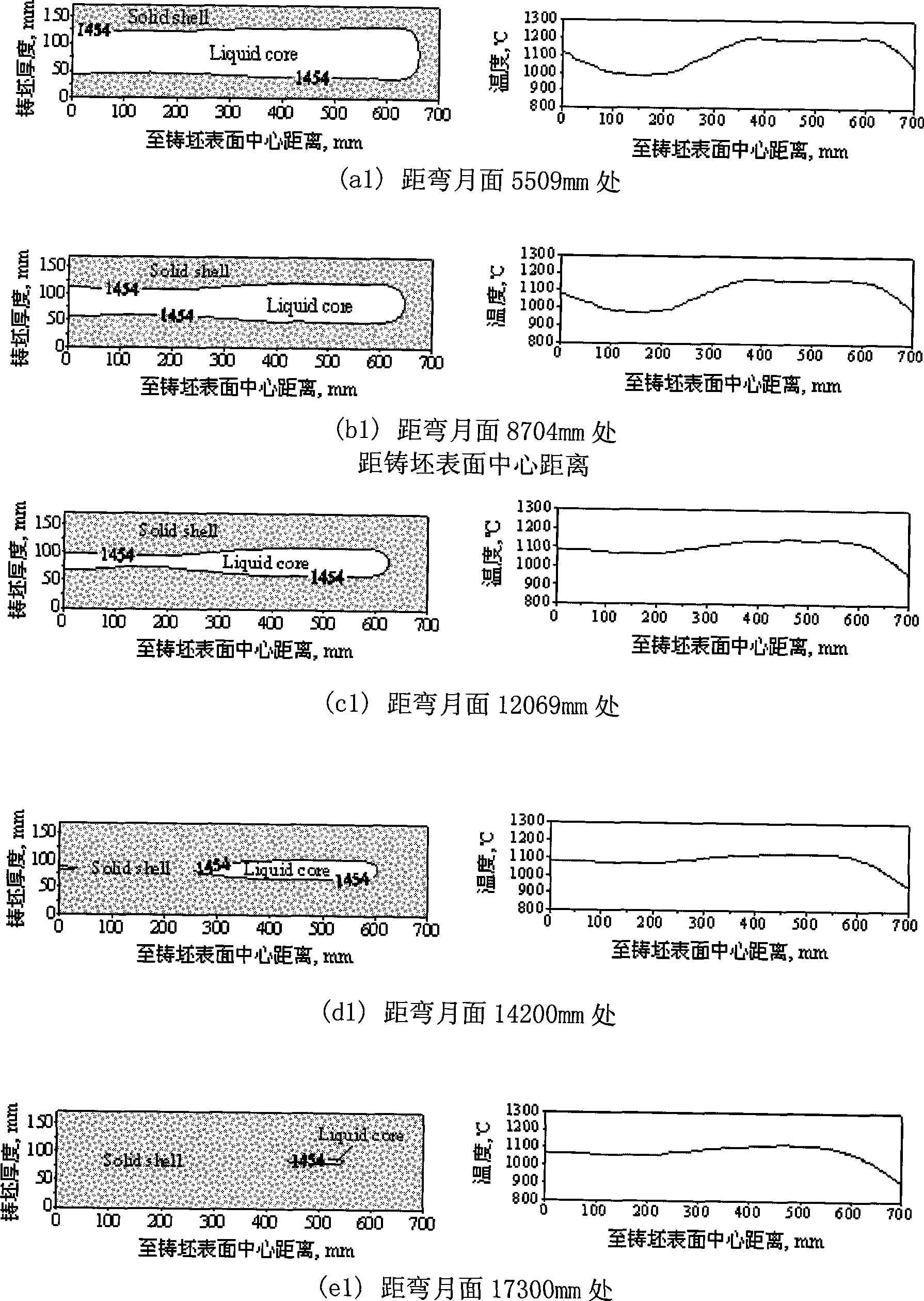

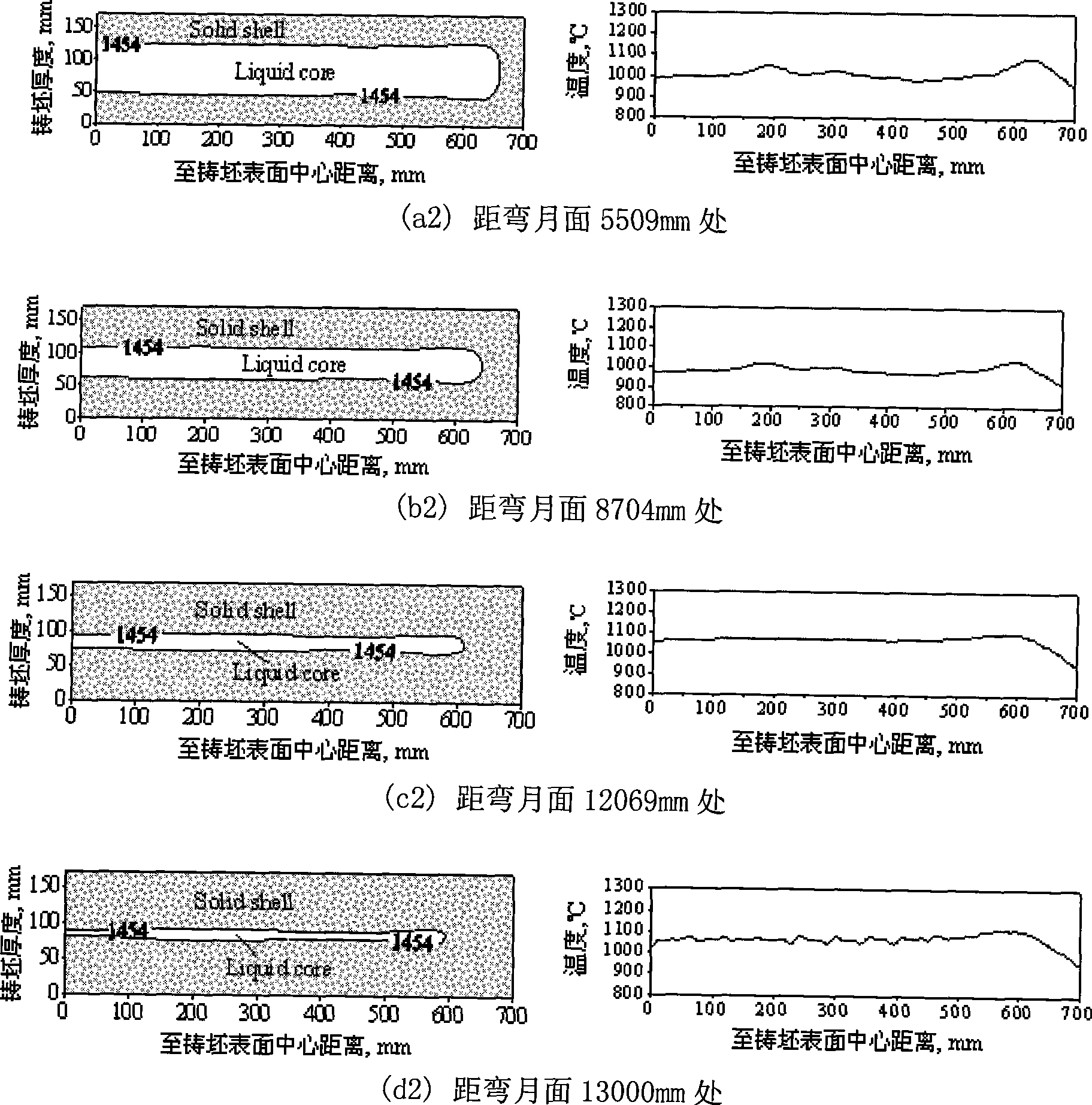

[0028] The invention is successfully applied and tested in the actual production of domestic continuous casting machines. For example, the layout structure of the secondary cooling nozzle of a certain continuous casting machine is not reasonable enough, and the cooling intensity distribution in the width direction of the slab is uneven.

[0029] Adopting the method of the present invention, that is: ① using a computer system to simulate the cooling and solidification behavior of the slab in a certain continuous casting process through a two-dimensional heat transfer simulation model of continuous casting slab solidification, and obtain the slab solidification in the entire continuous casting process Shell growth morphology and temperature distribution state values, when the secondary cooling intensity distribution is uneven, the solidification shell morphology of the continuous casting slab section and the surface temperature distribution in the width direction of the inner arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com