Method for automatically processing pipe fitting and equipment thereof

A technology for automatic processing and pipe fittings, applied in the field of automatic processing equipment, can solve problems such as the difficulty of fixing the threaded rod, the inconvenience of automatic pressing into the wear-resistant sleeve, and the difficulty of accurately controlling the feeding amount of the pipe fittings, so as to save labor costs and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

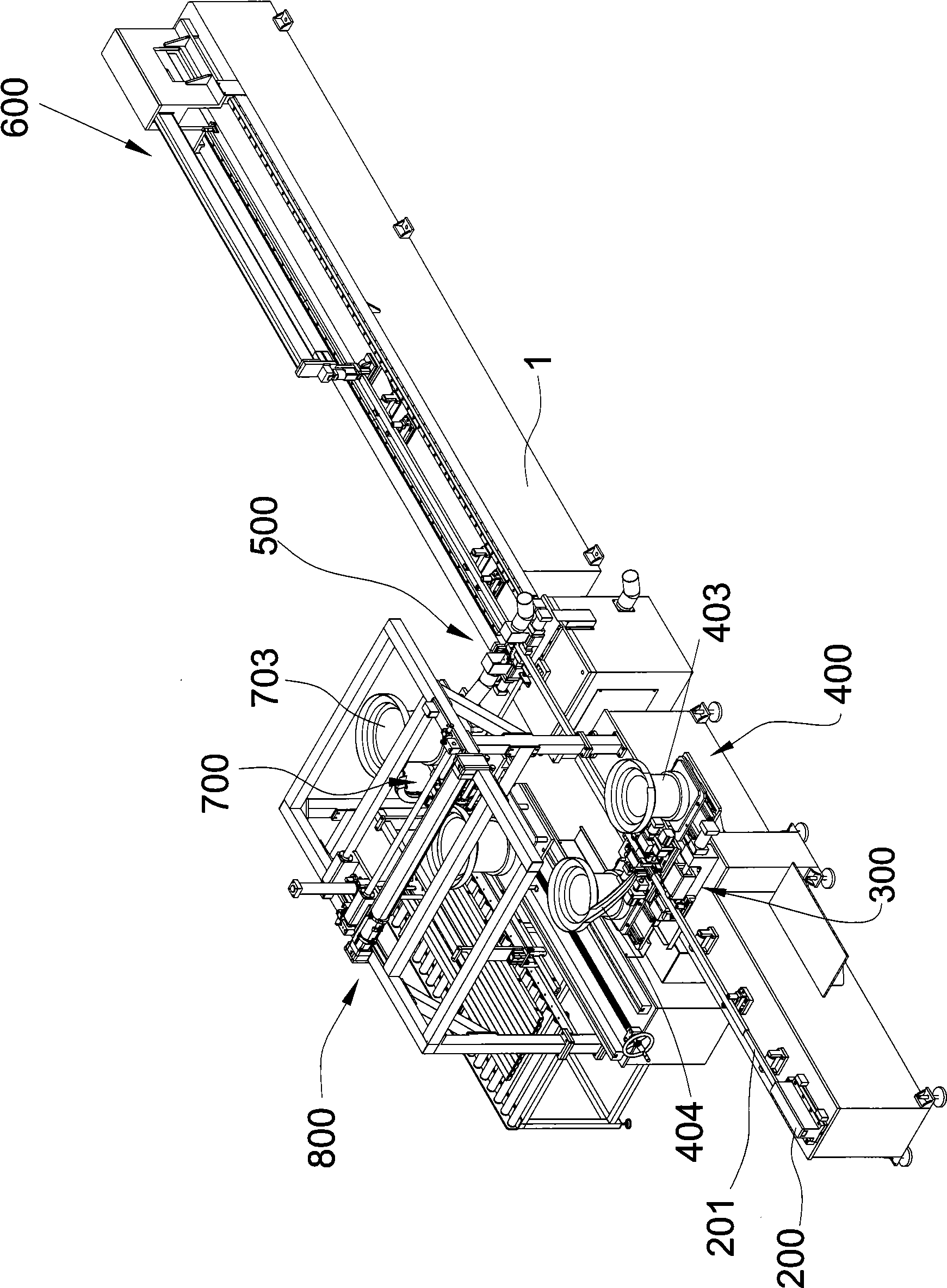

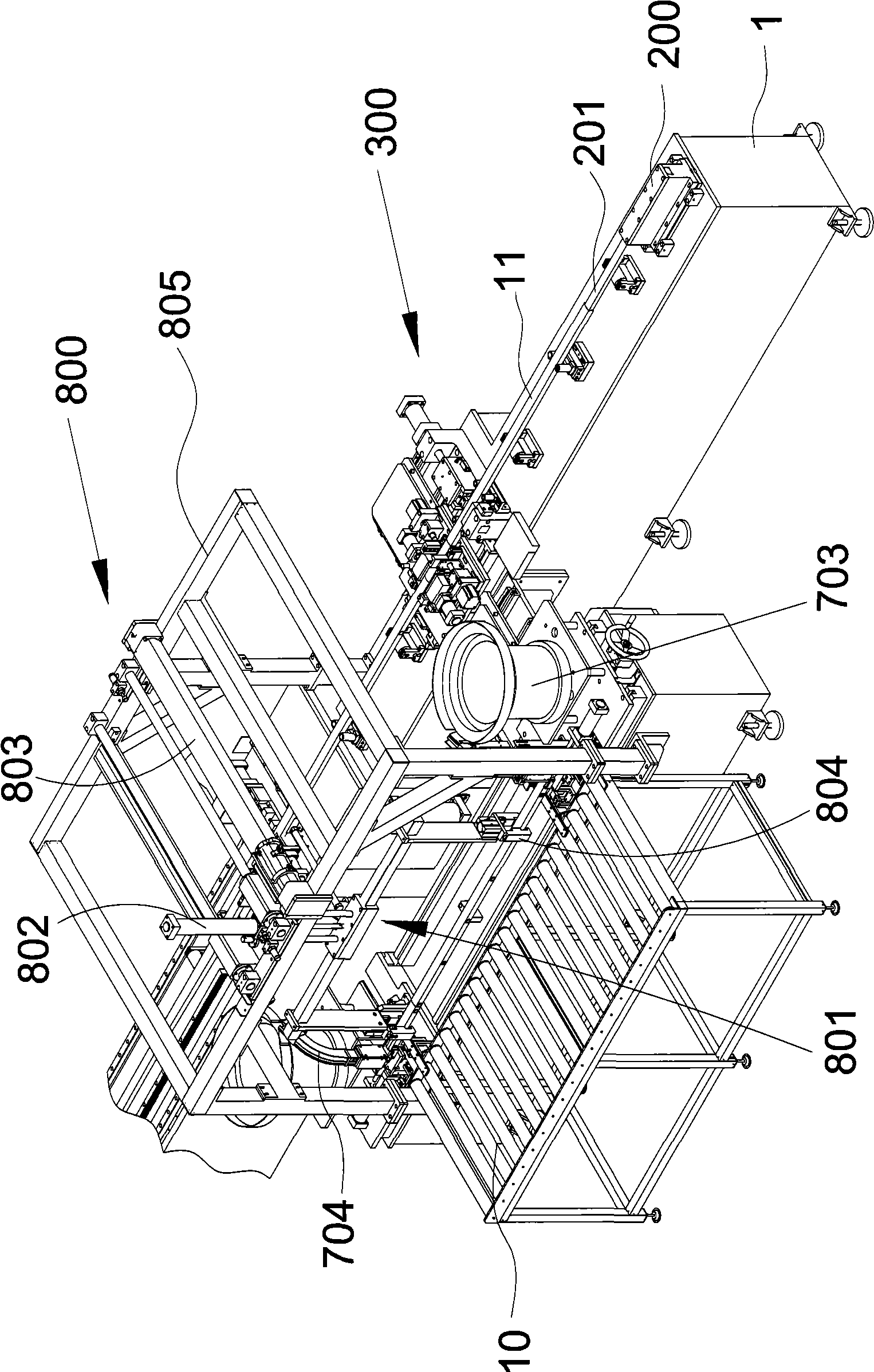

[0043] Attached below figure 1 to attach Figure 7 The content of the present invention will be described in detail.

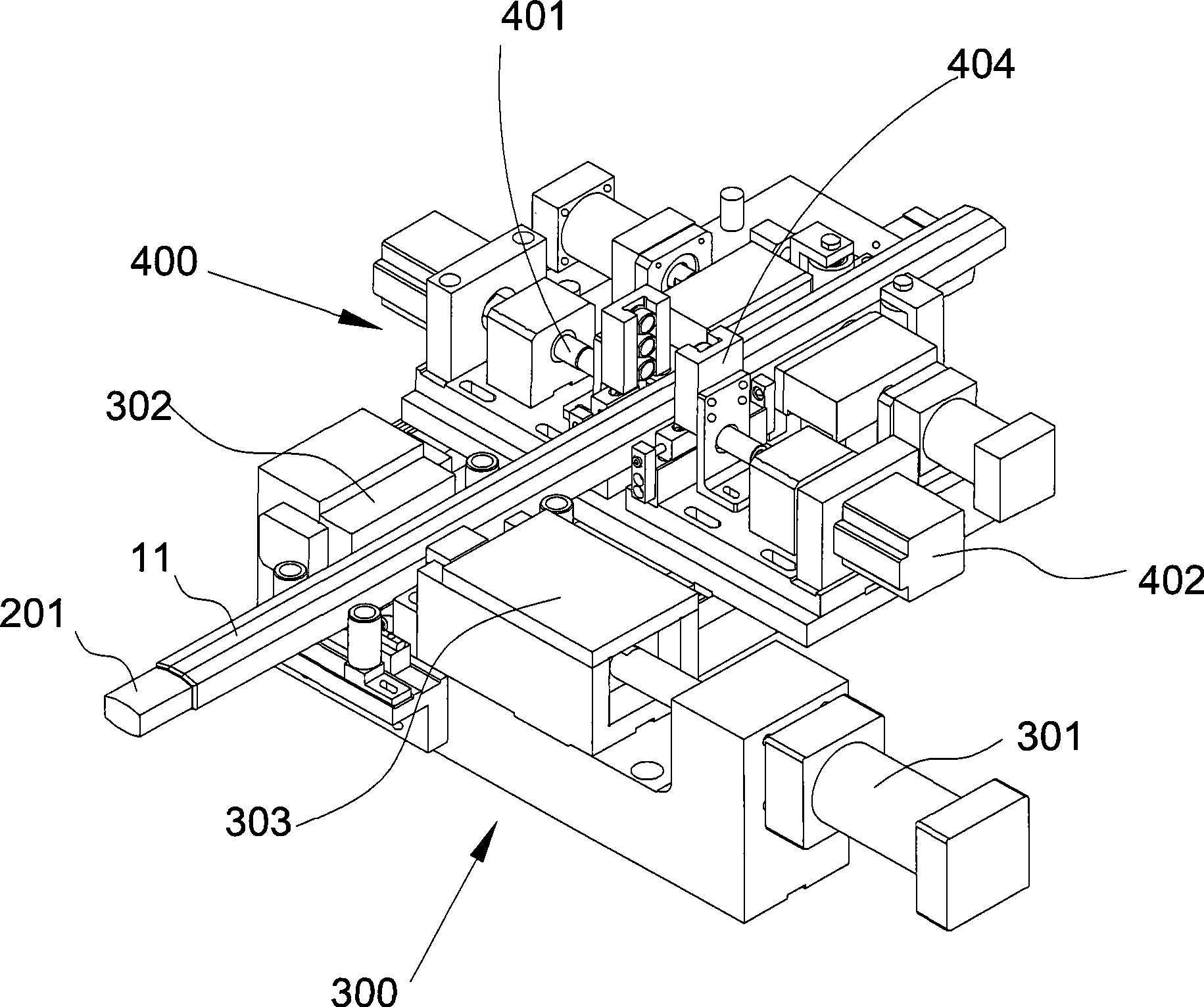

[0044] An automatic processing equipment for pipe fittings, which includes a workbench 1, on which a core-through rod 201, a punching mechanism 300, a wear-resistant sleeve pressing mechanism 400, a cutting mechanism 500, a clamping mechanism, and The feed mechanism 600 for moving the workpiece forward or backward, the piercing rod 201 extending from the front end of the workbench 1 to the punching mechanism 300;

[0045] The punching mechanism 300 includes an oil cylinder 301 fixedly connected to the workbench 1, a U-shaped positioning die 302 and a punch 303 provided with a punching needle thereon, and the positioning die 302 is fixedly connected to the piston rod of the oil cylinder 301 superior;

[0046] The wear-resistant sleeve press-in mechanism 400 includes a wear-resistant sleeve automatic feeding device, a wear-resistant sleeve press head 401, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com