A press-fitting device for composite exterior wall panels in construction engineering

A technology of construction engineering and press-fitting device, applied in the field of building wall panels, can solve the problems such as the inability to meet the improvement needs of enterprise combined wall panel processing efficiency and decorative effect, and the complex structure of combined wall panels, so as to achieve a wide range of use and easy assembly. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

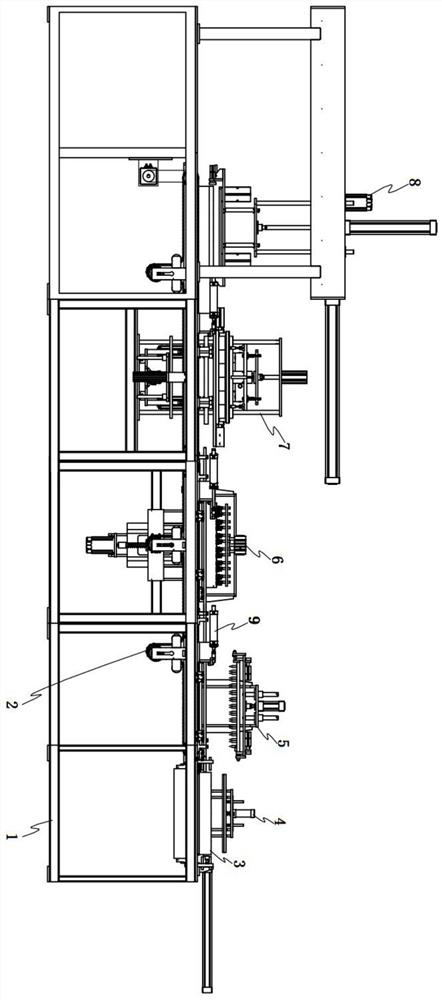

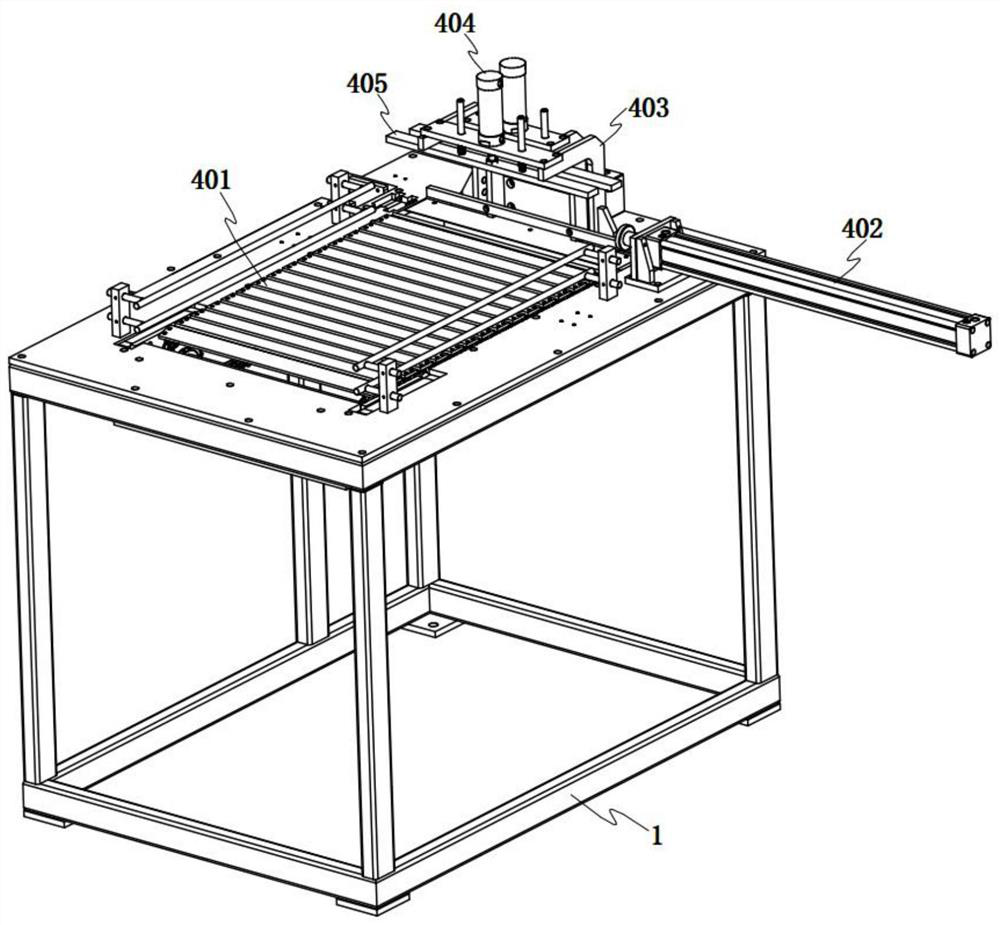

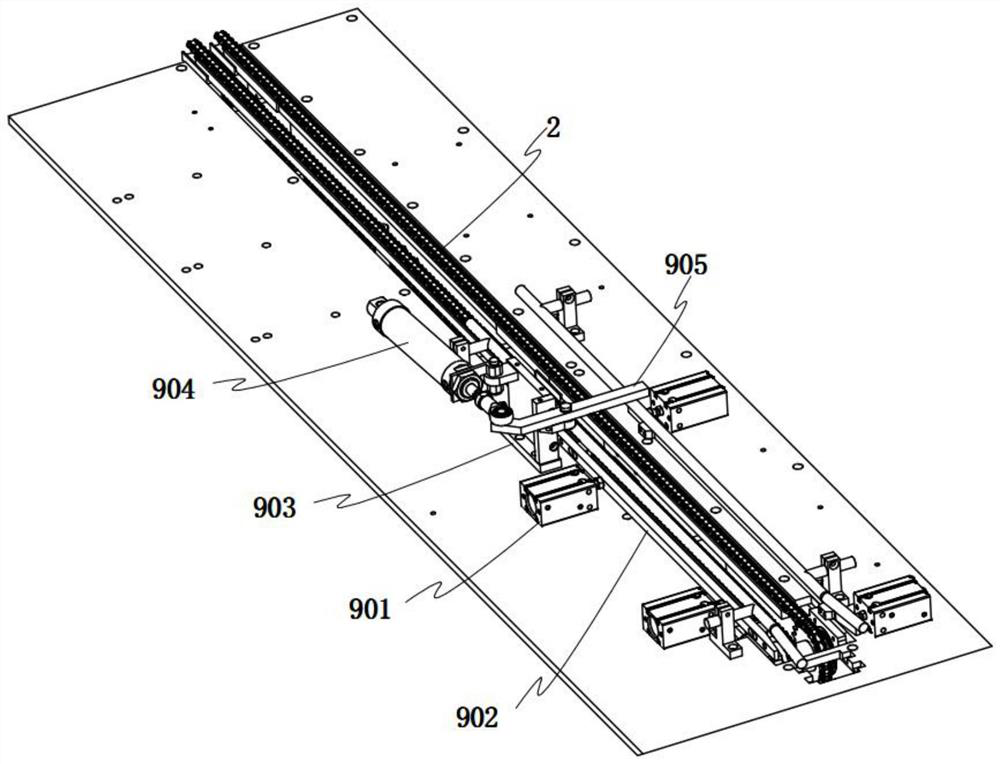

[0035] First, put the wall panels 3 on the conveyor belt 401 of the leveling input mechanism 4 one by one, and the conveyor belt 401 transports the wall panels 3 to the leveling frame 403 directly below, and then the leveling block 405 is driven by the pressing and leveling driving cylinder 404 to the wall panel 3 . The outer surface is flattened and pressed, and finally the flattened wall panels 3 are pushed one by one to the conveyor chain belt 2 on the table body 1 of the device by the pushing cylinder 402, and the wall panels 3 are transported to the punching mechanism 5 by the conveyor chain belt 2. Below, the limiting cylinder 904 of the limiting mechanism 9 drives the limiting rod 905 to rotate around the hinge of the limiting seat 903, and drives the limiting rod 905 to block the wall panel 3, thereby stopping the wall panel 3 from the conveyor chain. On the belt 2, then the clamping rod 902 is driven by the clamping cylinder 901 to firmly press the edges of the two sid...

Embodiment 2

[0037] When the wall panel 3 is transported directly below the exterior trim panel adding mechanism 6 , the wall panel 3 is first clamped by the clamping and limiting mechanism 9 , and then the conveying motor 612 of the exterior trim panel adding mechanism 6 drives the driving shaft 613 and the driving shaft 613 The chain belt between the driving shaft 615 and the driving shaft 615 runs, so that the running chain belt drives the outer trim panels stored in the outer trim panel storage frame 608 to move forward to the upper part of the frame groove 616, and then the lift motor 601 drives the vertical drive screw 603 rotates, thereby driving the lift top frame 605 to move up along the vertical slide rail 604, driving the lift top frame 605 to extend into the frame groove 616, and lift the outer trim panel on the upper part of the frame groove 616 upward, and then the horizontal displacement cylinder III609 The vertical displacement cylinder II 614 is driven to move to the upper ...

Embodiment 3

[0039]When the wall panel 3 is transported by the conveyor belt 2 to just below the pressing mechanism 7, the wall panel 3 is clamped by the clamping and limiting mechanism 9 first, and then the pressing cylinder 709 of the pressing mechanism 7 drives the vertical displacement plate 717 Vertically move down, and then the horizontal displacement cylinder II 718 on the vertical displacement plate 717 drives the fastening plate 716 to move forward, thereby driving the lower pressing plate 714 and the vertical displacement cylinder I713 to move above the wall plate 3, and then the vertical displacement The cylinder I713 drives the paddle 712 to be inserted into the lower pressing plate 714 and protrudes from the lower end surface of the plate body, while the horizontal displacement cylinder I706 of the pressing mechanism 7 drives the lower pressing seat 705 to slide along the horizontal slide rail 702, thereby driving the lower pressing seat 705. The press-fit bottom plate 708 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com