Degradable artificial trachea stent and production method thereof

An artificial trachea and a manufacturing method technology, applied in the field of biomedicine, can solve the problems of stenosis of the lumen, difficulty in breathing, and inability to climb and stretch the tracheal epithelium, and achieve the effects of less irritation, strong anti-infection ability, and beneficial to crawling repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

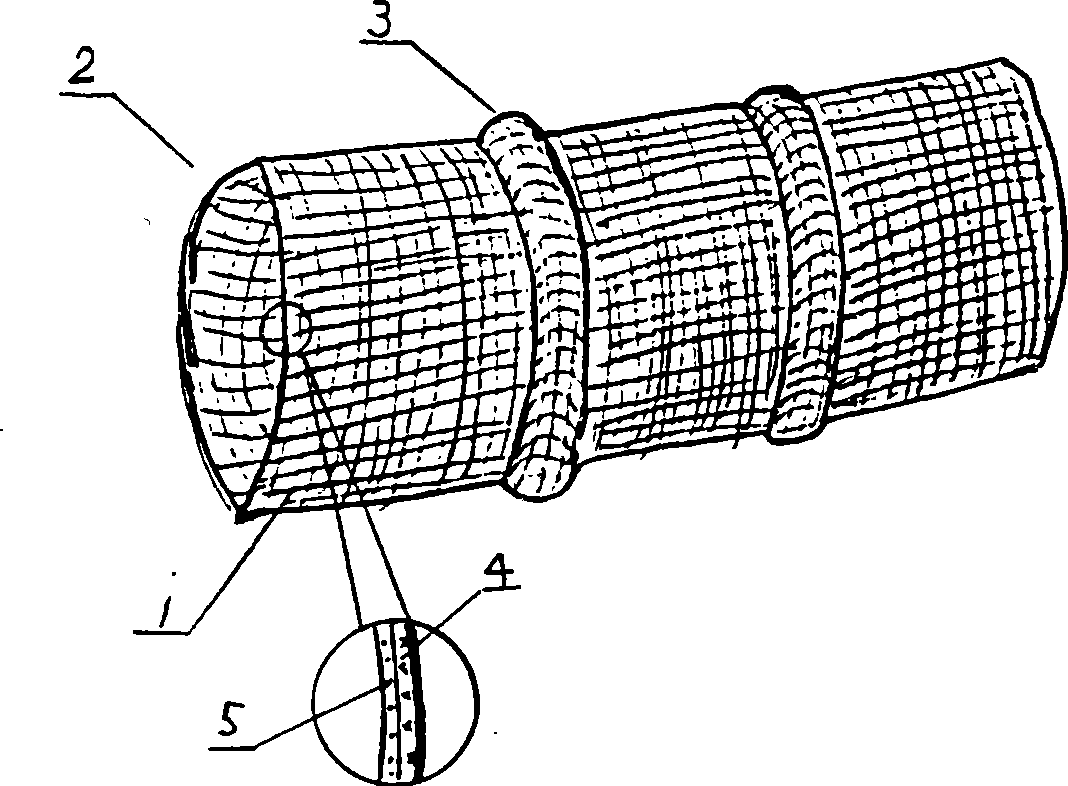

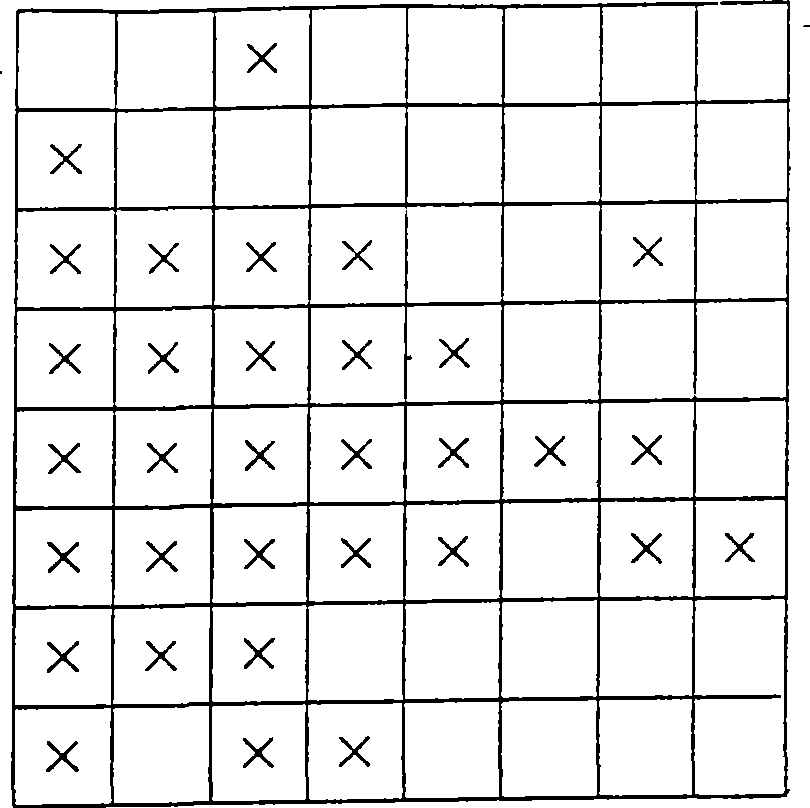

[0029] ① The warp and weft raw materials are polyglycolide monofilaments with a diameter of 0.15mm; the width of A (E) part is 2cm, and the density of warp and weft is 40×40 / cm; the width of part B (F) is 1.5cm, and the density of warp and weft is 40×45 / cm ; Fabric composition is ABABABA;

[0030] ② Loosely insert the anti-blocking mold into the small tubular ring composed of double-layer pipe walls surrounding the longitudinal axis of the pipe wall;

[0031] ③Soak in 2% collagen solution for 3 minutes, take it out, and dry;

[0032] ④Apply 2% chitosan solution evenly and tightly on the inner layer to close the mesh and maintain air tightness;

[0033] ⑤ After disinfection, vacuum dry and seal and store at 4°C.

Embodiment 2

[0035] ① The warp and weft yarn raw material is polydioxanone monofilament with a diameter of 0.27mm, the width of part A (E) is 1.5cm, and the density of warp and weft is 20×20 / cm; the width of part B (F) is 1cm, and the density of warp and weft is 20×22 Roots / cm; fabric composition is ABABA;

[0036] ② Loosely insert the anti-blocking mold into the small tubular ring composed of double-layer pipe walls surrounding the longitudinal axis of the pipe wall;

[0037] ③Soak in 2% collagen solution for 3 minutes, take it out, and dry;

[0038] ④Apply 2% chitosan solution evenly and tightly on the inner layer to close the mesh and maintain air tightness;

[0039] ⑤ After disinfection, vacuum dry and seal and store at 4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com