Deep hole drilling apparatus

A processing device and deep hole technology, applied in feeding devices, metal processing, automatic control devices, etc., can solve the problems of impossible drilling of deep holes, and achieve the effects of preventing diffusion, avoiding judgment deviation, and avoiding judgment errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

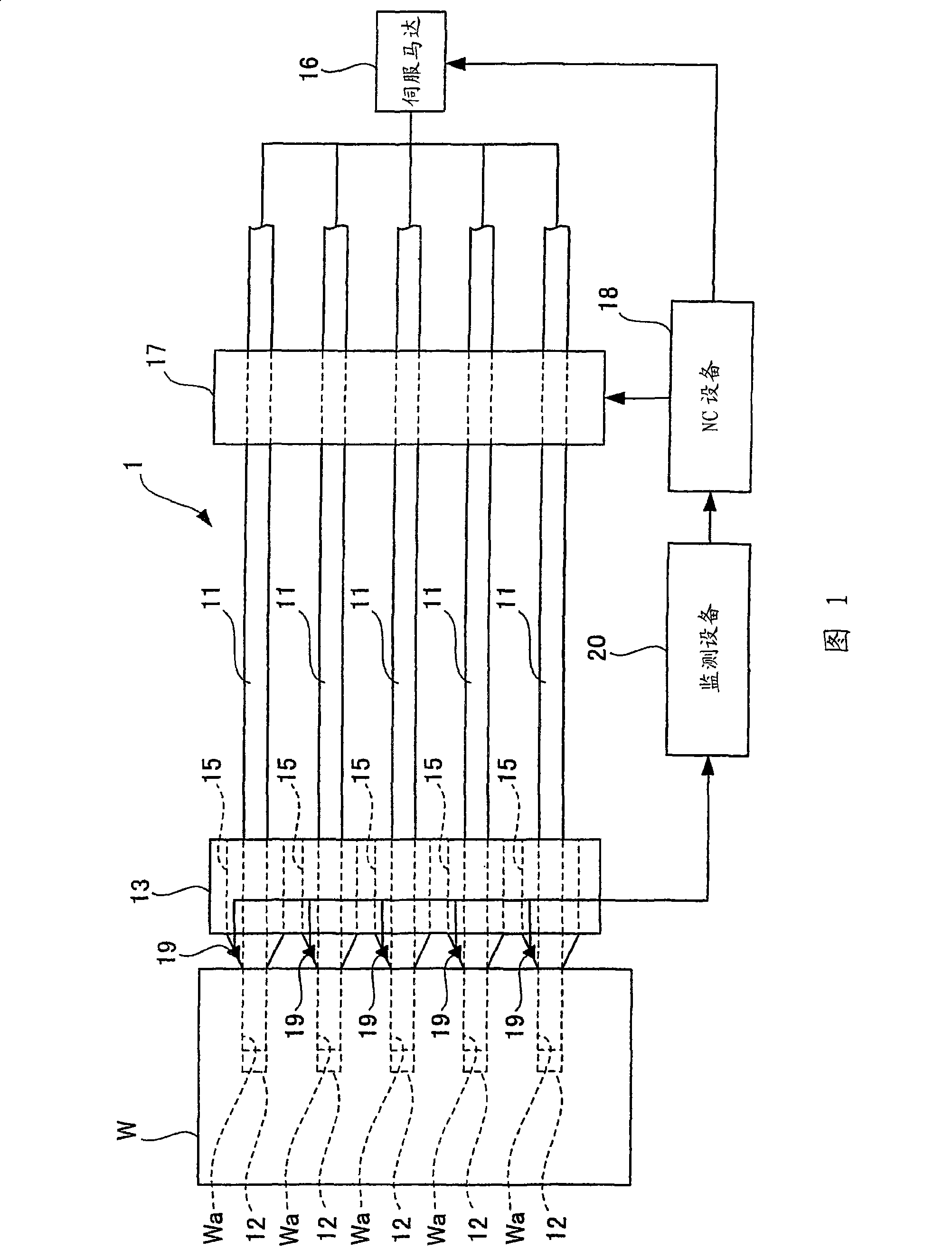

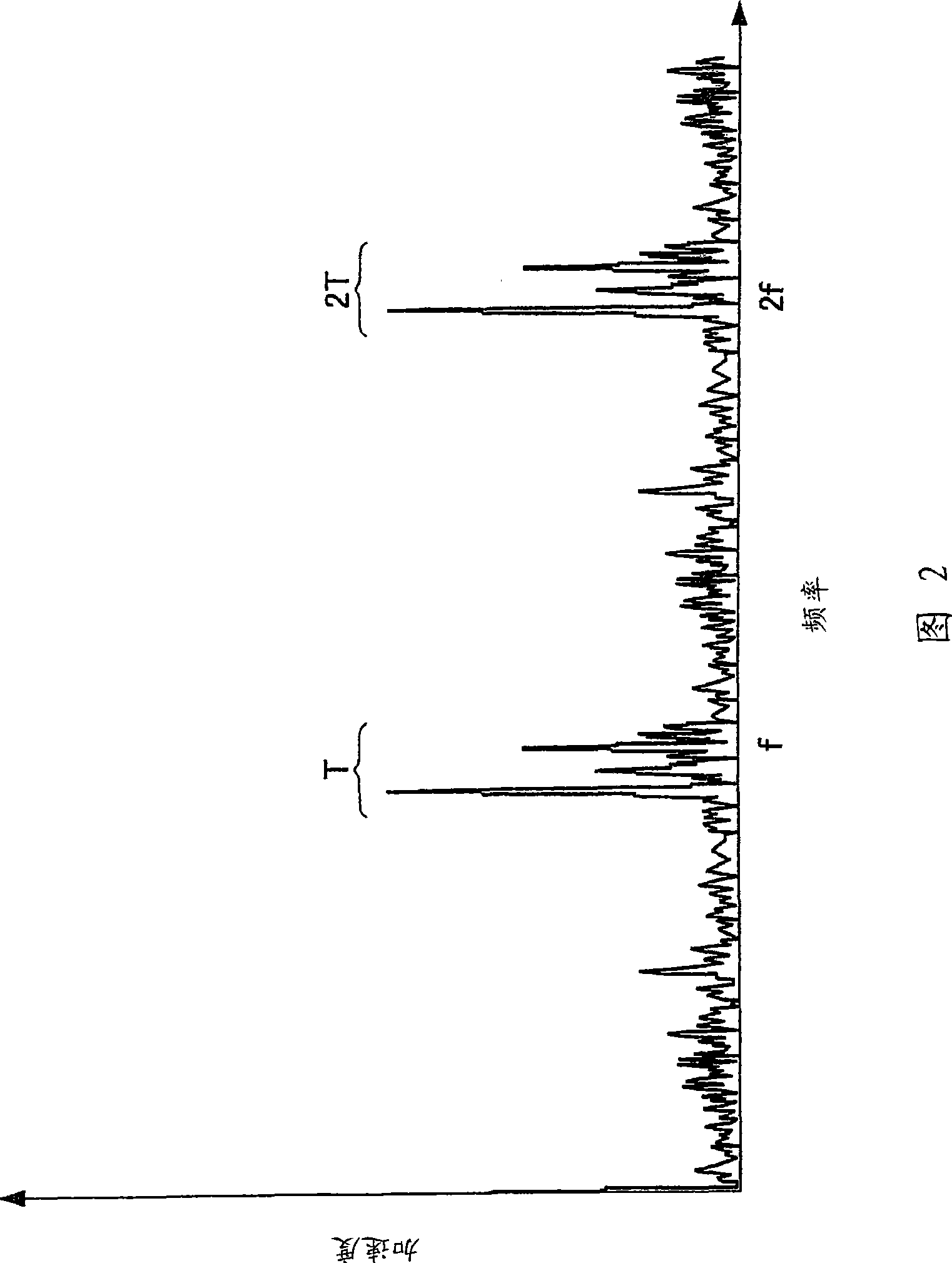

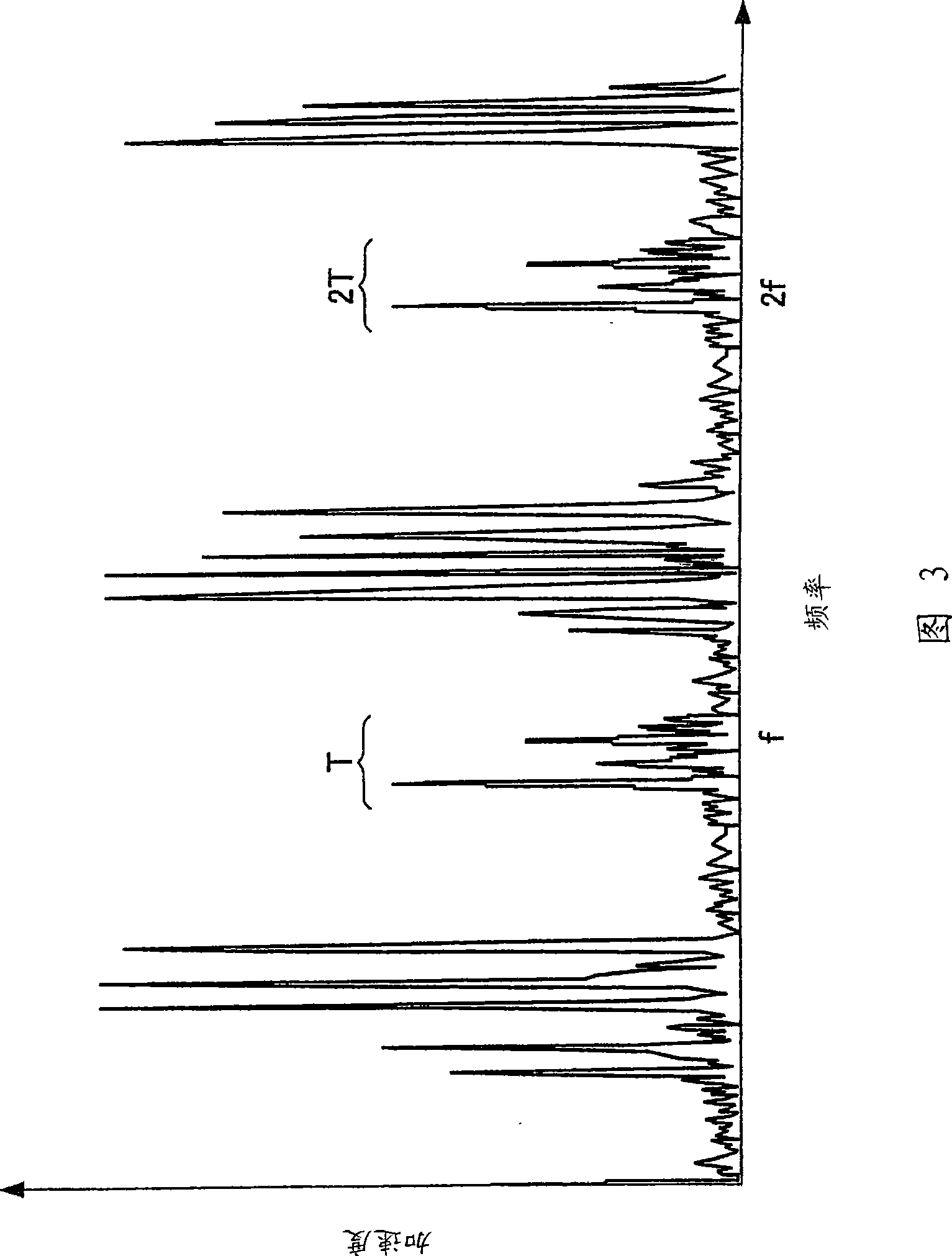

[0047]Details of the deep hole machining apparatus according to the present invention will be described below with reference to the accompanying drawings. Fig. 1 is a schematic diagram of a deep hole machining device according to an embodiment of the present invention. FIG. 2 is a graph showing the results of frequency analysis of acceleration. FIG. 3 is a graph showing the results of frequency analysis of acceleration when tool marks are generated. Fig. 4 is a graph showing temporal changes of the total value. FIG. 5 is a graph showing another method of setting a threshold. Fig. 6 is a schematic diagram of a deep hole machining device according to another embodiment of the present invention.

[0048] FIG. 1 shows a 5-axis BTA (Boring and Trepanning Association) machine tool, which is a deep hole drilling device for drilling a deep hole in a workpiece (object to be machined) W. The 5-axis BTA machine tool includes five drill rods 11 each having a hollow structure. Each dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com