Fast releasing apparatus used for rolling door

A rolling shutter door and quick release technology, applied in the field of rolling shutter doors, can solve the problems of difficult operation and maintenance, easy aging of batteries, complex structure, etc., and achieve the effect of eliminating mechanical connection, simple and compact structure, and easy to popularize and apply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

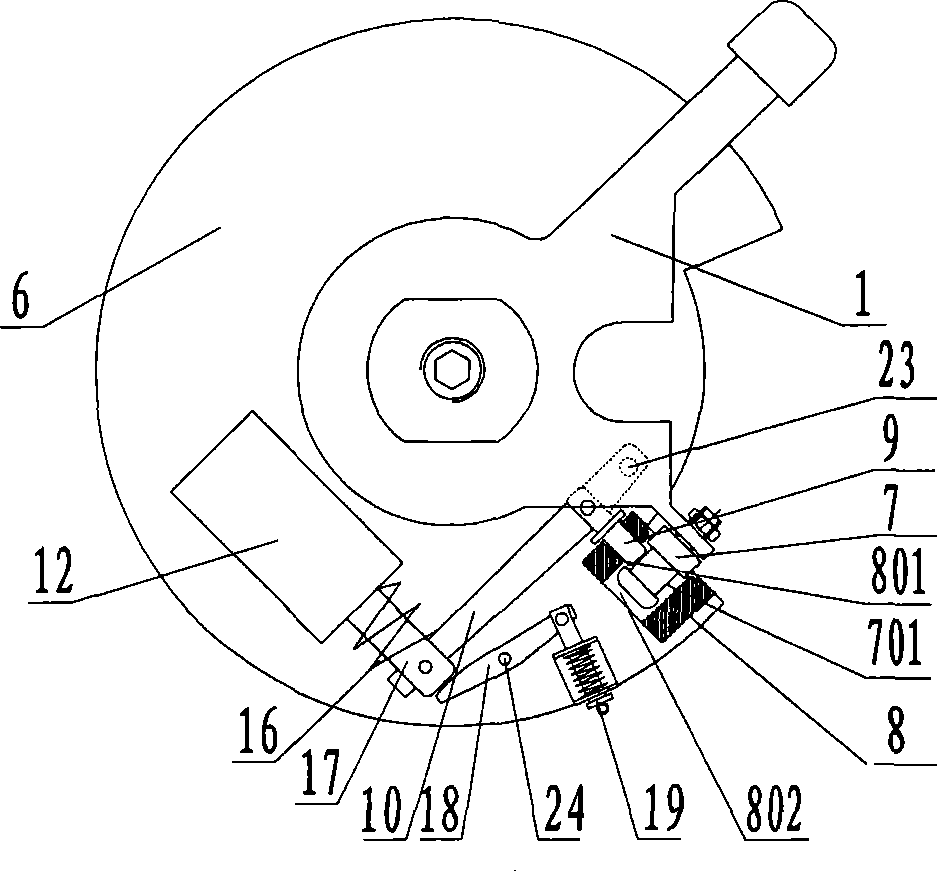

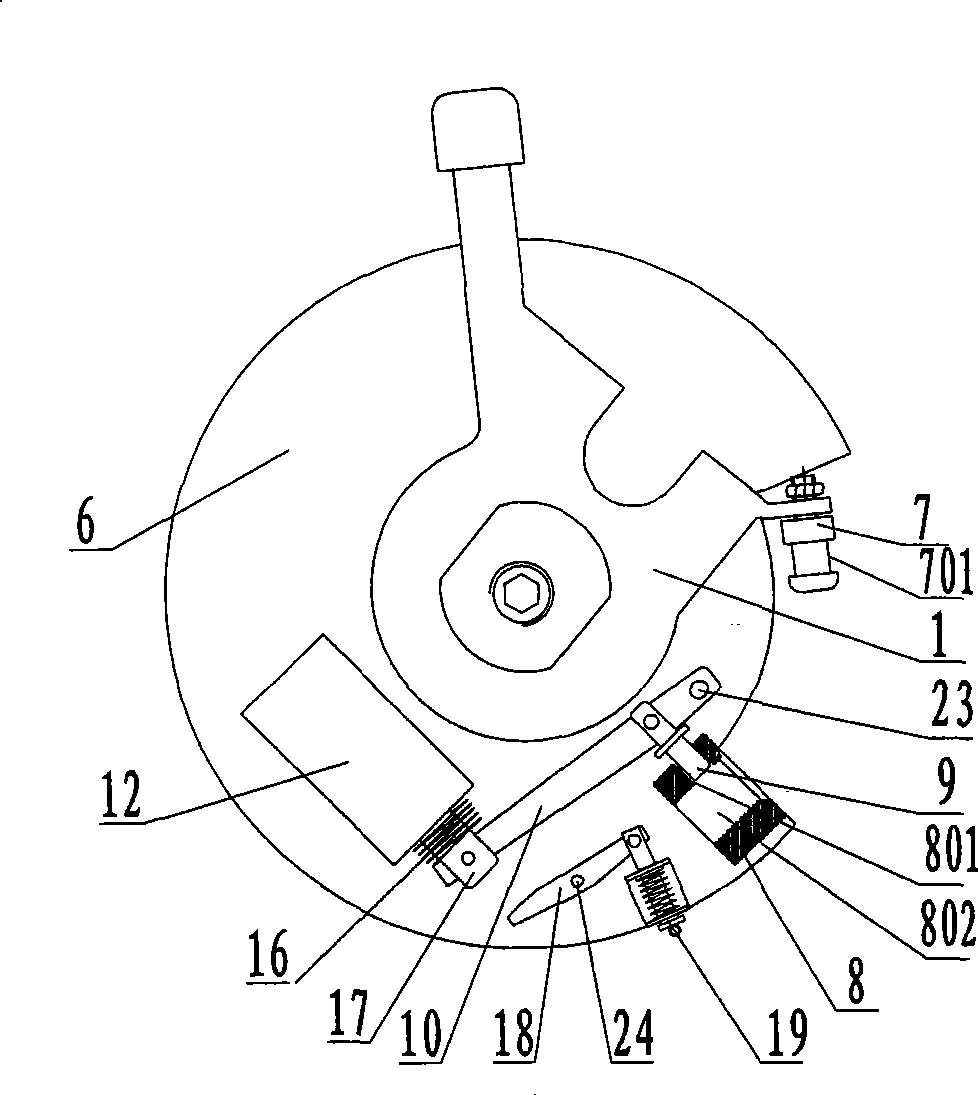

[0050] Such as Figure 1 to Figure 11 As shown, the present invention is used for the quick-release device of rolling shutter door, and it comprises mounting plate 6, drive plate 1, lifting mechanism and electric control start-up mechanism, and lifting mechanism comprises rotating rod 3 and positioning sleeve 4 that keeps fixed, and rotating rod 3 One end is fixed on the brake lever 14 top, and the other end links to each other with the drive plate 1, is provided with can drive the thread angle that brake lever 14 moves up and down between the rotating lever 3 and the positioning sleeve 4. The bottom end of the brake lever 14 is connected to the brake disc 15, and the motor brake lever 14 drives the brake disc 15 to clutch to form a clutch gap T. In this embodiment, the rotating rod 3 is a rotating screw, the positioning sleeve 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com