Waterproof coating material for paper pallet and water-proof paper pallet thereof

A technology of waterproof coatings and paper pallets, applied in the field of coatings, can solve the problems of easy moisture absorption of paper pallets, and achieve the effects of strong adhesion, convenient handling, and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

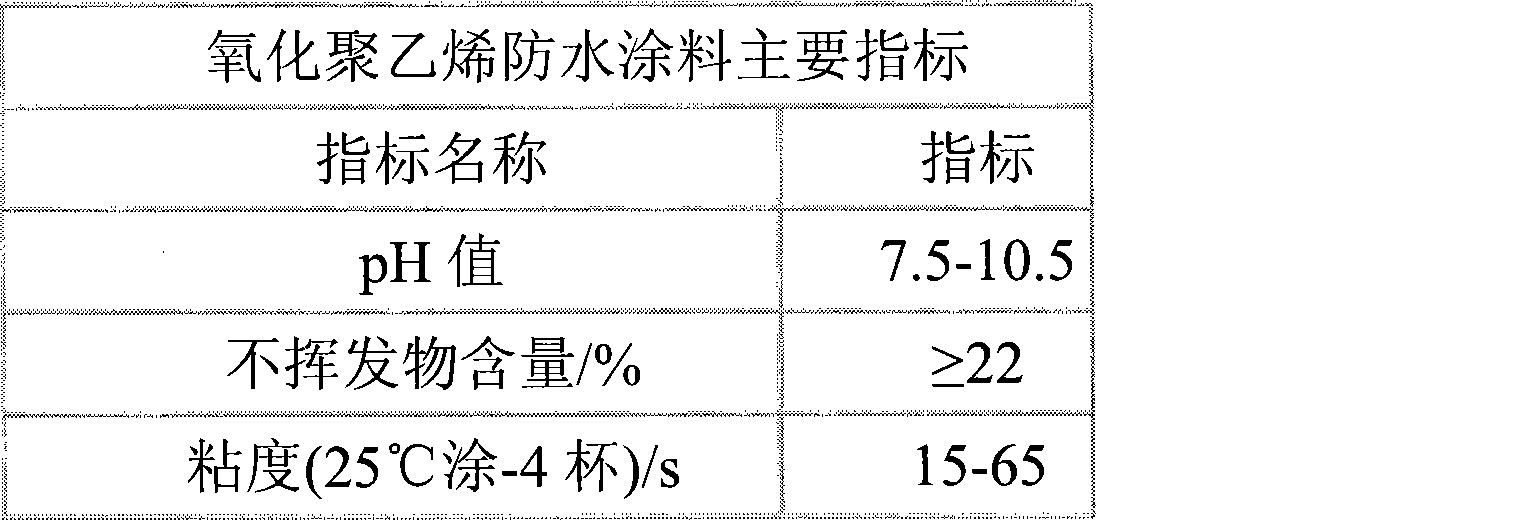

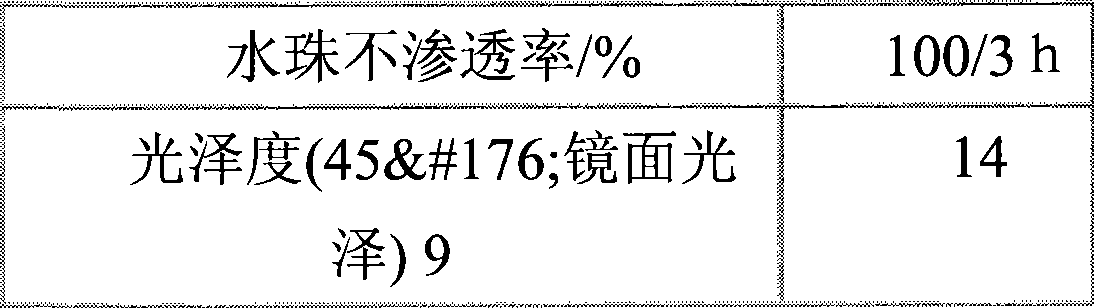

Image

Examples

Embodiment 1

[0033] Take 400Kg of thinner water and 150Kg of polished oil, mix in a weight ratio of 4.0:1.5, and stir in a stirring tank for about 15 minutes until the mixture is uniformly mixed and becomes transparent, making a waterproof coating and forming a paper pallet with a clean surface After soaking in the waterproof coating for 10 seconds, take it out, and then place the paper pallet in the direction of the pit pattern for 10 seconds to allow the excess waterproof coating in the pit pattern to flow out, and then place the paper pallet outdoors to dry naturally After drying, the paint will evaporate completely in about 30 minutes. The resulting waterproof paper pallet is I.

Embodiment 2

[0035] Take 360Kg of Tianna water and 75Kg of polished oil, mix according to the weight ratio of 4.8:1.0, and stir in a stirring tank at room temperature for about 12 minutes until the mixture is uniformly mixed and transparent, and it is made into waterproof coating, and the surface is clean. The paper pallet is soaked in the waterproof coating for 12 seconds and then taken out. Then the paper pallet is placed in the direction of the pit pattern for 10 seconds to allow the excess waterproof coating in the pit pattern to flow out, and then the paper pallet is placed Air dry outdoors, and the paint will evaporate completely in about 30 minutes. The resulting waterproof paper pallet is II.

Embodiment 3

[0037] Take 400Kg of thinner water and 64Kg of polished oil, mix at a weight ratio of 5.0:0.8, and stir in a stirring tank for about 10 minutes until the mixture is uniformly mixed and becomes transparent to make a waterproof coating and form a paper pallet with a clean surface. After soaking in the waterproof coating for 15 seconds, take it out, and then place the paper pallet in the direction of the pit pattern for 15 seconds to allow the excess waterproof coating in the pit pattern to flow out, and then place the paper pallet outdoors to dry naturally Dry, about 35 minutes, the paint volatilizes completely. The resulting waterproof paper pallet is III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com