Lyotropic liquid crystal flooding system, as well as preparation method and use thereof

A lyotropic liquid crystal system technology, applied in the field of surfactant lyotropic liquid crystal system and its preparation, can solve the problems of no lyotropic liquid crystal oil displacement system, increase the viscosity of the oil displacement system, and decrease the oil displacement efficiency, and achieve Easy to implement, good oil displacement effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

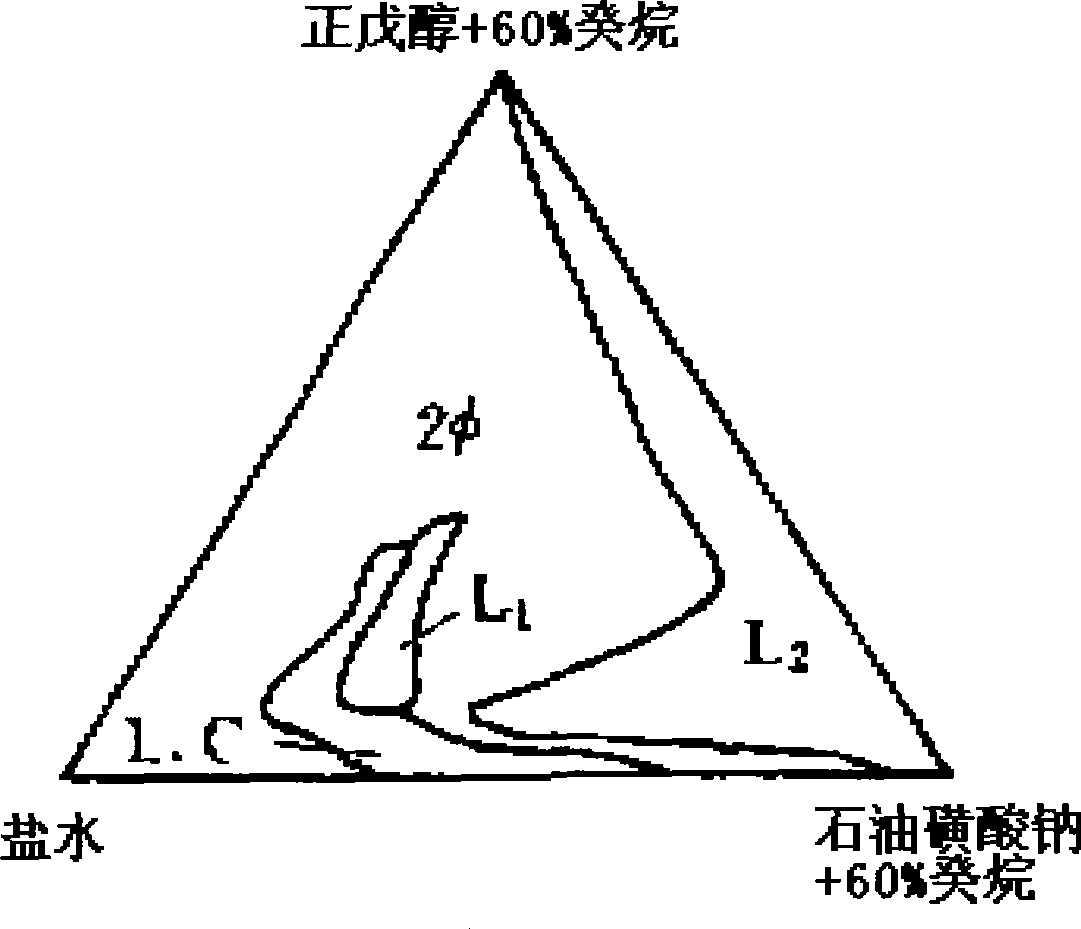

[0039] Embodiment 1, taking sodium petroleum sulfonate / n-pentanol / decane / brine system as an example, preparation of lyotropic liquid crystal flooding system

[0040] (1) Method for determining the region of lyotropic liquid crystal in the ternary phase diagram

[0041] In the regular triangle coordinate diagram, its three sides are equally divided into 10 equal parts, and its three vertices are respectively salt water (0.5%-5% sodium chloride), which is placed in the lower left corner; petroleum sodium sulfonate+60% decane ( bottom right corner); n-pentanol + 60% decane (top corner). First, on the sideline (n-pentanol-sodium petroleum sulfonate) on the sideline of the top corner of the salt water, take points from top to bottom (respectively table No. 1, 2, 3...9 samples), calculate each according to the leverage rule Composition of sample points. Generally, the mass of each sample point is 1 gram, and sodium petroleum sulfonate, n-pentanol, and decane are weighed in sequence ...

Embodiment 2

[0052] Example 2: Sodium oleate lyotropic liquid crystal flooding system

[0053] Detailed preparation and oil displacement experiment method are with embodiment 1, and difference is:

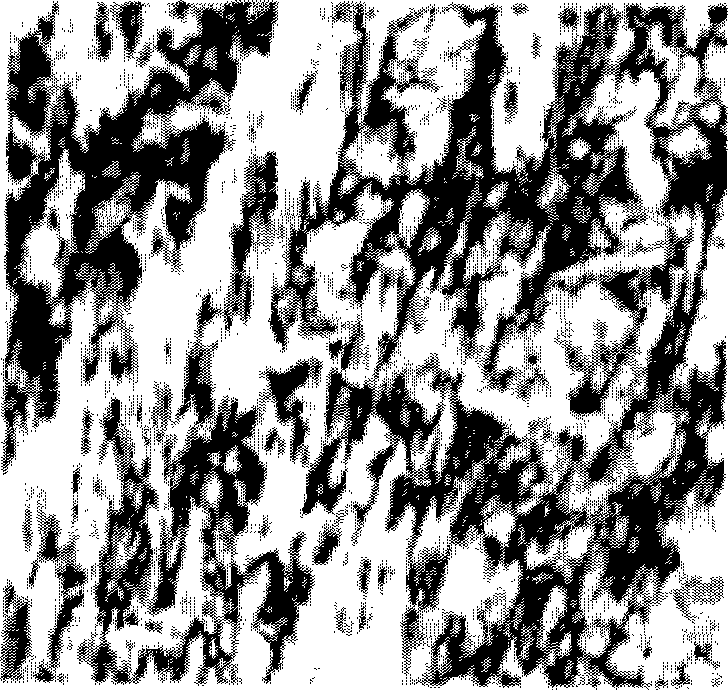

[0054] (1) The formula of sodium oleate lyotropic liquid crystal flooding system: 29.5wt% sodium oleate+26.3wt% oleic acid+44.2wt% (3.57%wt sodium chloride) aqueous solution, obtain texture photo under polarizing microscope, measure It is lamellar liquid crystal;

[0055] (2) Indoor simulated oil displacement experiment:

[0056] a. Crude oil and formation parameters: Crude oil from the No. 5 Oil Production Plant of Zhongyuan Oilfield, density 0.834g / cm 3 ; Crude oil viscosity 28.2mPa s (60 ℃); Formation permeability: 0.72μm 2 ; Formation temperature: 75°C.

[0057] b. Basic data of artificial core: experimental temperature: 75°C; gas permeability: 0.76μm 2 ;

[0058] Pore volume: 40.2cm 3 ; Saturated oil volume: 28.9cm 3 .

[0059] c. Experimental results: water flooding recovery: 6...

Embodiment 3

[0060] Example 3: AEO-9 lyotropic liquid crystal flooding system

[0061] (1) The formula of AEO-9 lyotropic liquid crystal: 30.5% AEO-9+13.0% n-butanol+56.5% (1.67% sodium chloride) aqueous solution, measured as lamellar liquid crystal;

[0062] (2) Indoor simulated oil displacement experiment

[0063] a. Crude oil and formation parameters: crude oil from Chunliang Oil Production Plant of Shengli Oilfield, density 0.873g / cm 3 , crude oil viscosity 19.3mPa s (60℃), formation permeability 0.185μm 2 , the formation temperature is 70°C.

[0064] b. Basic data of artificial core: experimental temperature: 70°C; gas permeability: 0.20μm 2 ;Pore volume: 40.2cm 3 ; Saturated oil volume: 39.1cm 3 .

[0065] c. Experimental results: the recovery rate of water flooding is 57.43wt% OOIP; the recovery rate of 0.3Vp lamellar liquid crystal chemical flooding is 20.71wt% OOIP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com