Solid phase sludge joint treatment method and use

A technology of sludge treatment and combined treatment, which is applied in the direction of sludge treatment, application, energy and wastewater treatment, etc., can solve the problems of immature urban sludge treatment technology, and achieve the goal of improving nitrogen retention effect, saving cost and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

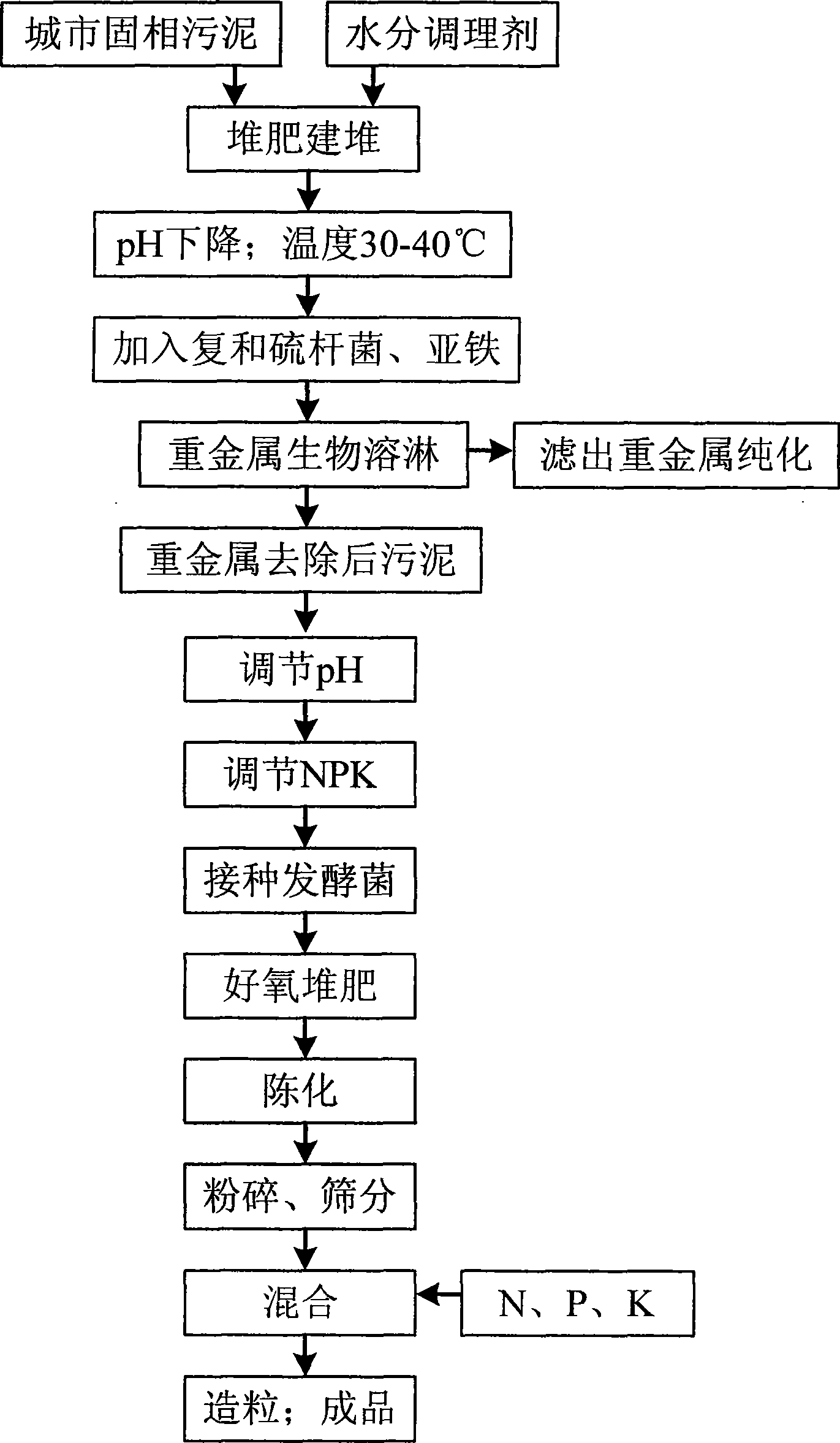

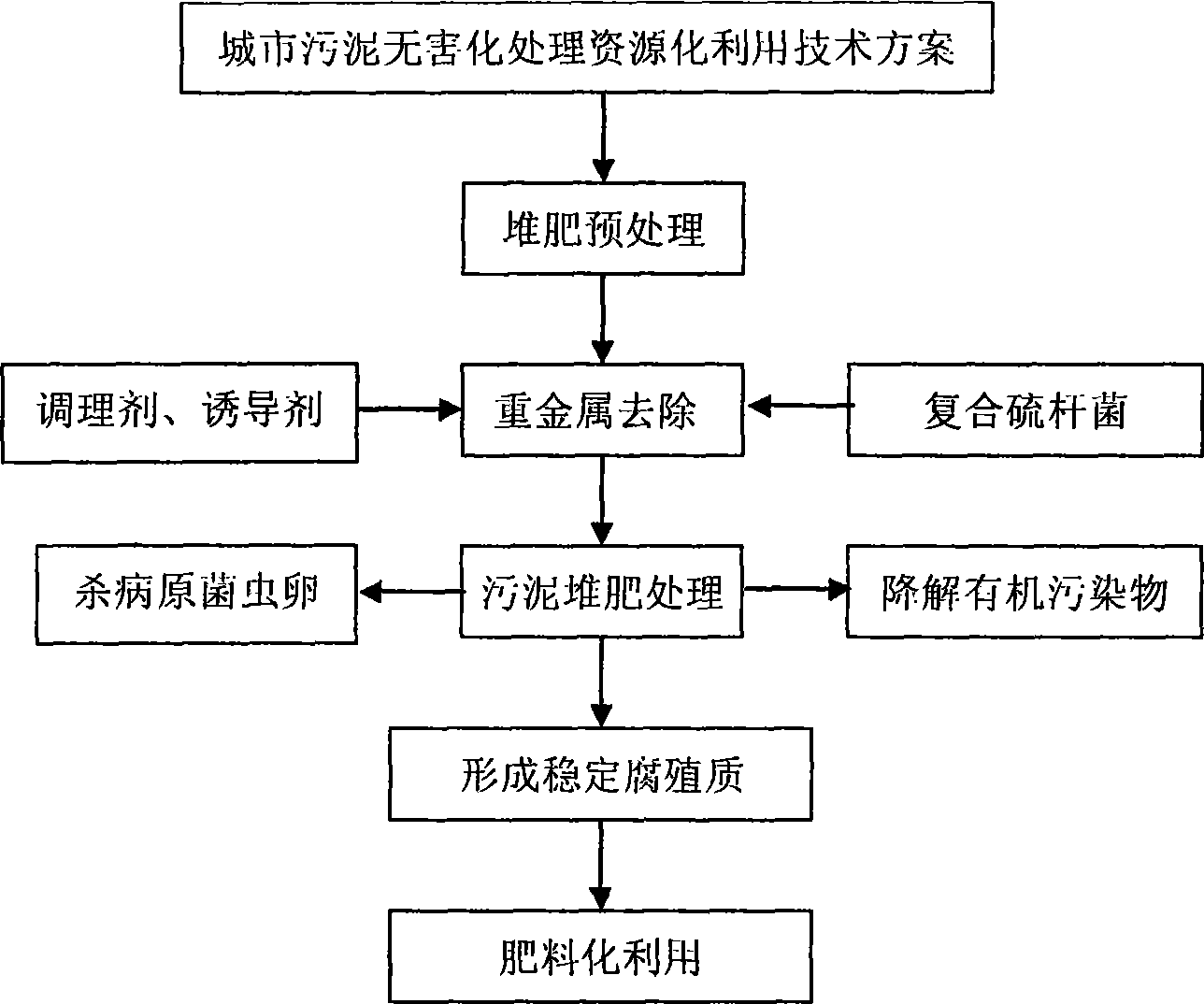

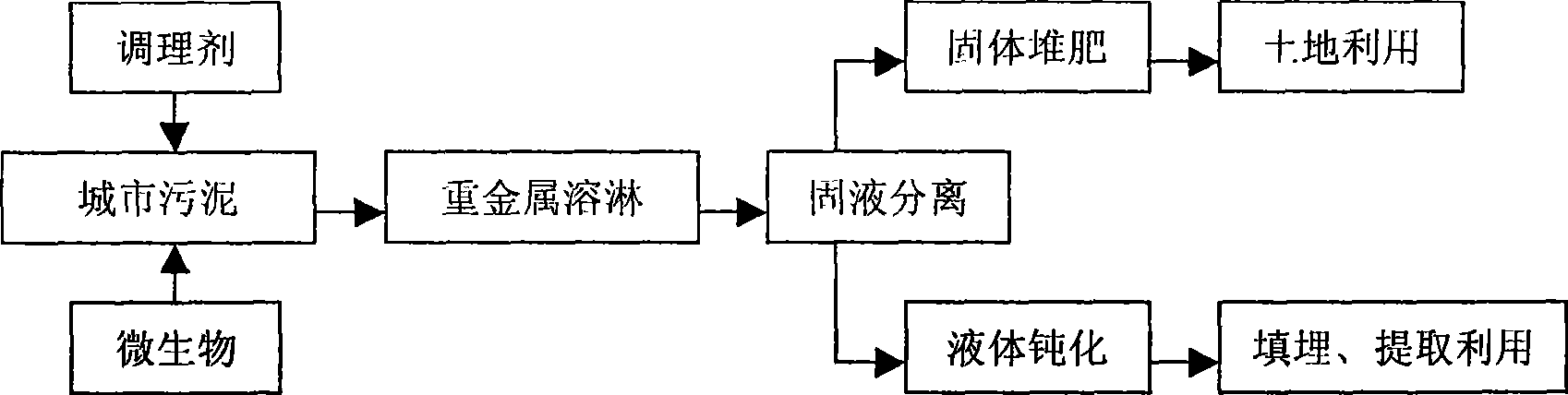

[0032] Solid phase sludge treatment test of Chengdu sewage treatment plant, related process such as figure 1 , figure 2 , image 3 shown.

[0033] Test period: from January 2006 to the end of November 2007.

[0034] Test location: Chengdu Xinfan Town Base and Mopanshan Base of Chengdu Helibao Biological Fertilizer Co., Ltd.

[0035] Test material: solid phase sludge, taken from Chengdu Sewage Treatment Plant.

[0036] Sludge takes 100t as a treatment unit and is divided into 4 treatments. The number of CK treatment is 0#, and 3 groups of parallel experiments are set up for raw sludge processing treatment, numbers: 1#, 2#, 3#.

[0037] CK treatment (0#): 2kg of fresh sludge is sampled for every 10t of raw sludge, and regulators are added in the same proportion for each treatment to ensure the consistency of test and test results. Store individually after air drying. Finally, pulverize the air-dried sludge, mix it thoroughly, and sample 1kg for inspection. The heavy metal...

Embodiment 2

[0066] The same parts as in Example 1 will not be described again, but the difference is: after starting the sludge aerobic composting treatment, the compost material is inoculated with bacterial strains to perform bioleaching heavy metal removal treatment. Send hot air into the compost to raise the temperature inside the compost and keep it at 30-35°C, pH value ≤7, oxygen concentration ≥12, leaching time 10-15 days, after the bio-leaching heavy metal removal treatment is completed, continue to sludge Aerobic composting.

Embodiment 3

[0068] The same as Example 1 will not be repeated, and the difference is: after composting starts, increase the amount of acid preparation, lower the pH value for leaching (make the pH value reach 5), keep the oxygen concentration at 10%, and leaching Time 10d, after the bioleaching heavy metal removal treatment, continue to carry out ordinary aerobic composting treatment. Heavy metals were significantly removed. The heavy metal content of treated sludge is shown in Table 5.

[0069] Table 5 Heavy metal content of treated sludge

[0070] Types of heavy metals As Cd Pb Cr Hg content(%) ≤0.0004 ≤0.0001 ≤0.0022 ≤0.0156 ≤0.0001

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com