Lower lockpin body, double-acting coupler and coupler buffering mechanism

A technology of buffer device and locking pin body, which is applied to traction devices, transportation and packaging, railway car body parts, etc. Good manufacturability, suitable for mass production, the effect of consistent rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

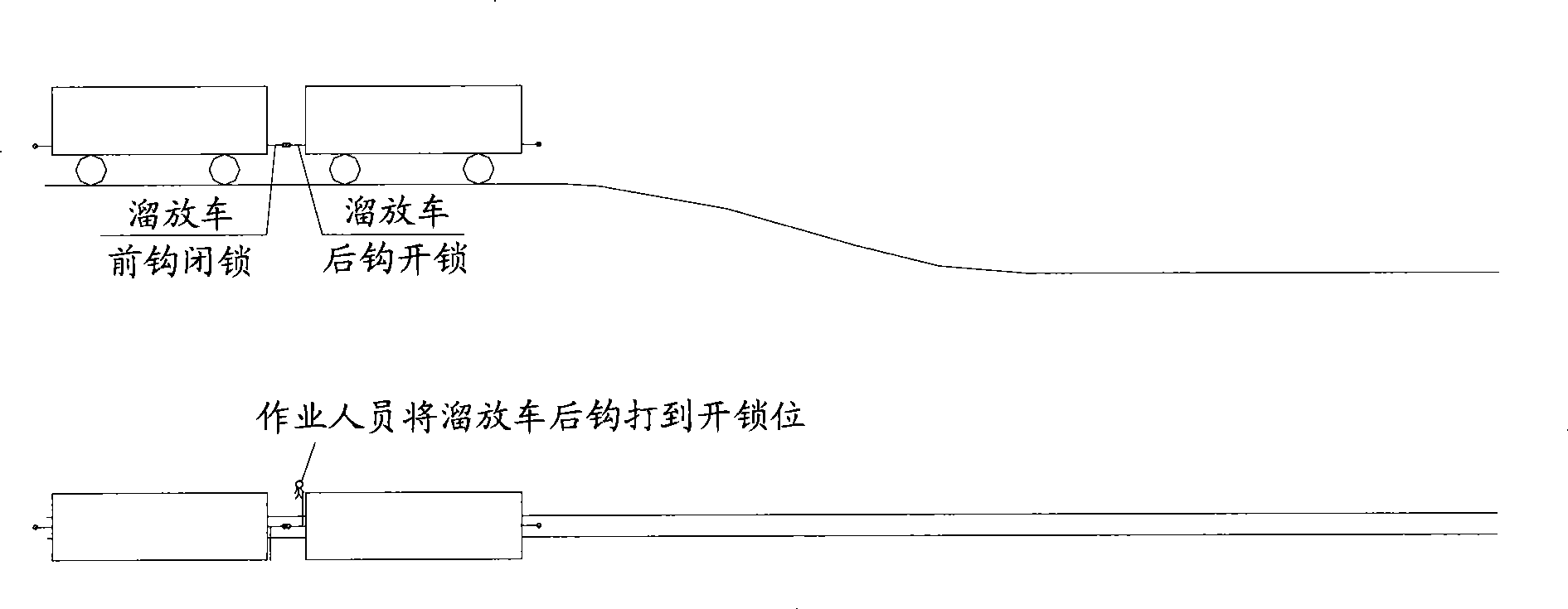

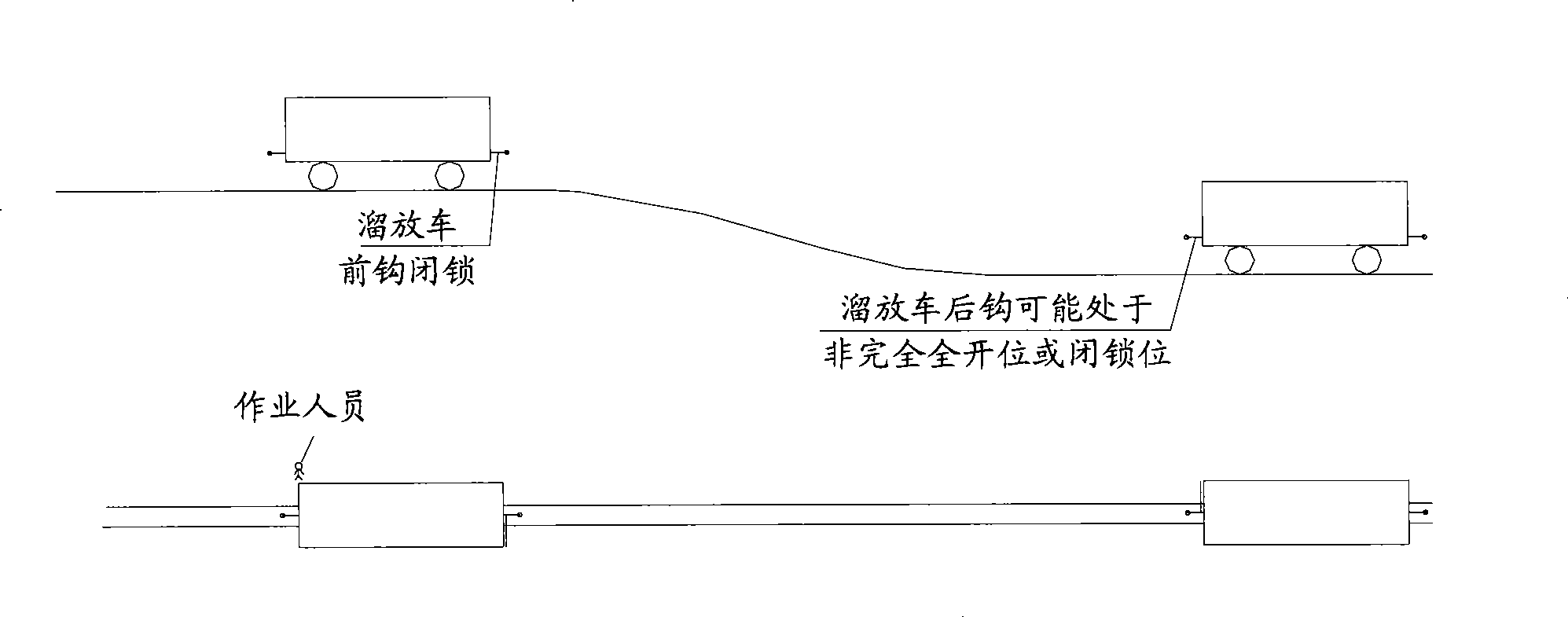

[0029] The core of the present invention is to provide a lower lock pin body with two coupler lift rod hanging holes, which is used to be hinged between the lower lock pin and the lower lock pin hook of the coupler, so as to be connected to the two sides of the coupler respectively. The coupler lift rod is connected to meet the needs of double-sided uncoupling operation, which is suitable for train marshalling operations such as hump shunting.

[0030] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

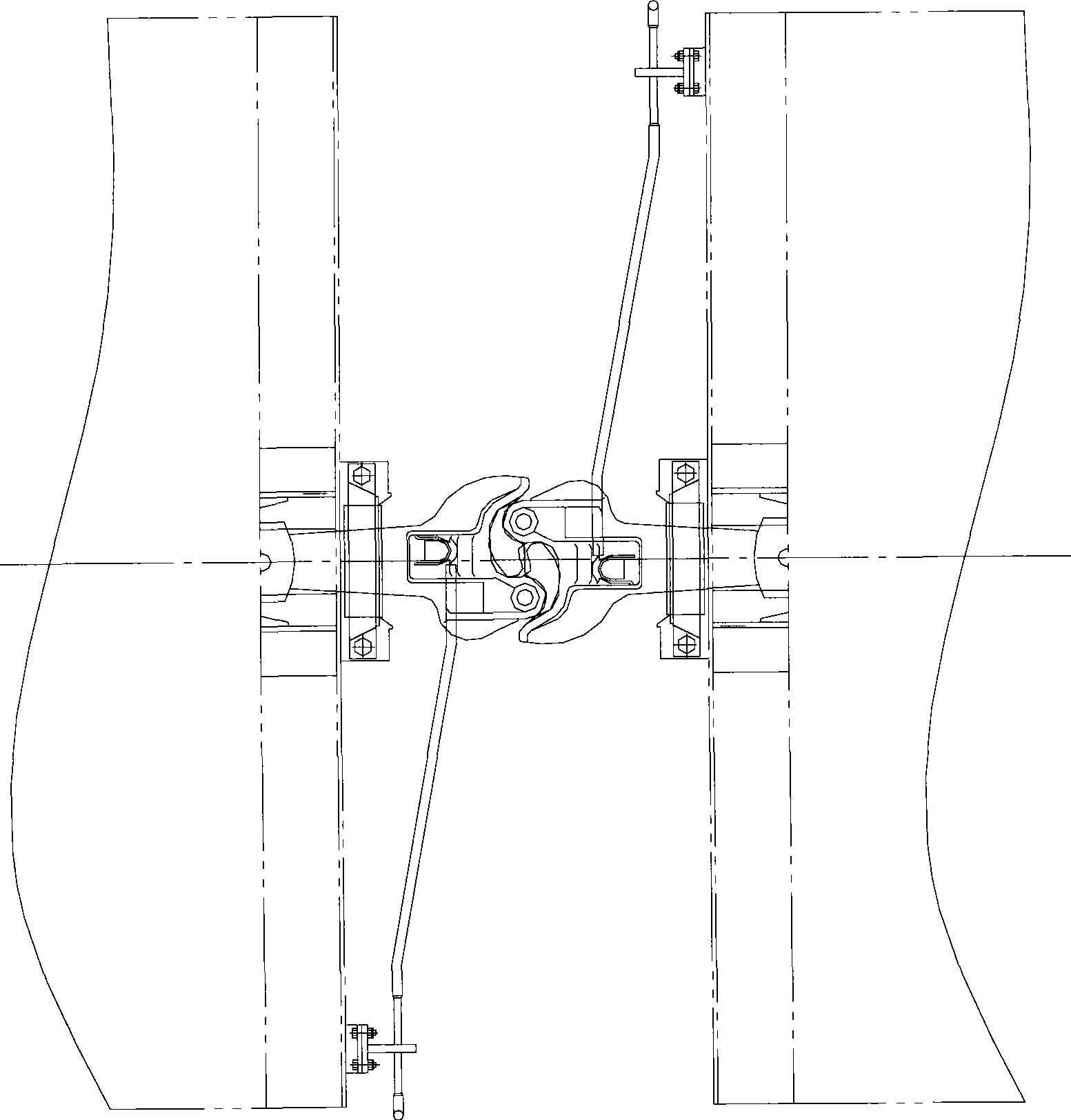

[0031] see Figure 3a with Figure 3b ,in, Figure 3a It is the front view of the lower lock pin body of the present invention; Figure 3b yes Figure 3a A view from direction A.

[0032] Such as Figure 3a As shown, the lower lock pin body 1 has two coupler lift rod hanging holes 11 and 12, which are respectively arranged at the two side ends of the lower lock pin body 1 .

[0033] combine Figure 3b As shown, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com