Numerical control method for accurate striking of screw press

A screw press, precise technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problem that the striking energy cannot be controlled digitally, and achieve the effect of improving the quality and consistency of the workpiece, improving the life of the mold, and improving the striking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

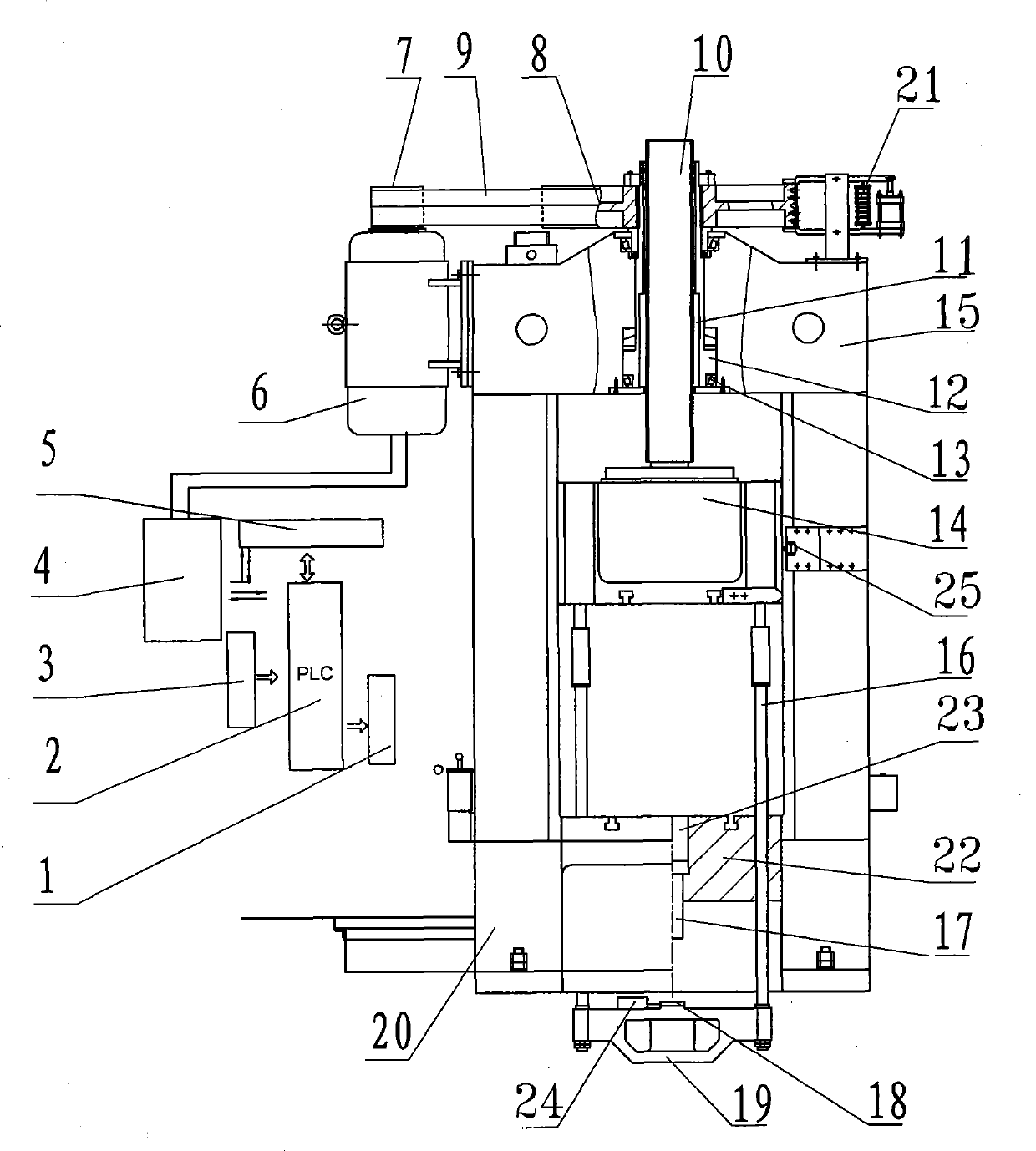

[0013] The present invention will be further described below in conjunction with accompanying drawing:

[0014] The screw press includes a fuselage 20, a brake 21, a workbench 22 installed at the bottom of the fuselage 20, a beam 15 installed on the top of the fuselage 20, a steel sleeve 12 with bearings installed on the beam 15, and a steel sleeve 12 fixedly installed in the steel sleeve 12. The nut 11 at the lower end and the flywheel 8 fixedly installed on the outer upper end of the steel sleeve 12, the flywheel 8 is connected with the driving wheel 7 installed on the output shaft of the switched reluctance motor 6 through the belt 9, the screw rod 10 passes through the steel sleeve 12 and connects with the nut 11 threaded connection, the lower end of the screw rod 10 is provided with a slide block 14, and the workbench is provided with a through step hole 23 corresponding to the directly below the slide block 14, and the ejector rod 17 is installed in the step hole 23 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com