Oil adjuvant of inactivated vaccine

An inactivated vaccine and oil adjuvant technology, which is applied to medical preparations containing active ingredients, antibody medical ingredients, refining to remove heteroatoms, etc., can solve the problem of poor performance stability of white oil injections, unstable vaccine performance, and fragile Dairy product performance and other issues, to achieve the effect of reducing vaccine cost, small resistance, and single component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] One, first prepare mannitol oleate

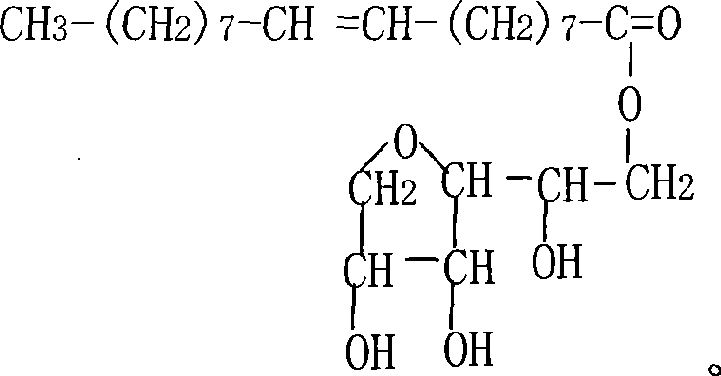

[0024] Take 40g of mannitol under the protection of nitrogen, and dehydrate at 195°C for 0.50 hours, then slowly add 80g of oleic acid and 0.20g of sodium hydroxide NaOH, which are equivalent to 2.0 times and 1 / 200 times the weight of 40g of mannitol, respectively, and keep the temperature constant Fatification 3 hours, obtain the emulsifier of mannitol oleate, the structural formula of this mannitol oleate is:

[0025]

[0026] 2. Preparation of white oil for injection

[0027] 1. Preparation of raw materials

[0028] The paraffin base is distilled by a distillation method, and the distilled fraction at 270-320° C. is used as the white oil raw material for injection.

[0029] 2. Remove impurities from raw materials

[0030] The hydrogen and white oil raw materials are simultaneously fed into the hydrogenation reactor at a volume ratio of 500 to carry out the first-stage hydrogenation reaction. The hydrogen passes through the r...

Embodiment 2

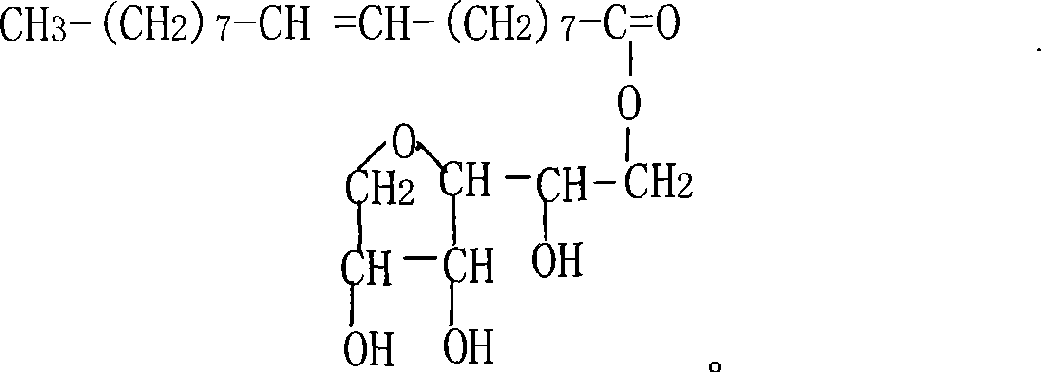

[0043] One, first prepare mannitol oleate

[0044]Also get 40g mannitol under the protection of nitrogen, dehydrate under the condition of 190 ℃ for 0.40 hours, then slowly add 60g oleic acid and 0.18g sodium hydroxide NaOH which are equivalent to 1.5 times and 1 / 220 times of the weight of 40g mannitol respectively, Constant temperature lipidation for 2.5 hours, the emulsifier of mannitol oleic acid was obtained, the structural formula of this mannitol oleic acid was the same as the above-mentioned embodiment.

[0045] 2. Preparation of white oil for injection

[0046] 1. Preparation of raw materials

[0047] The intermediate crude oil base is distilled by distillation method, and the distilled fraction at 279-312° C. is used as the white oil raw material for injection.

[0048] 2. Remove impurities from raw materials

[0049] The hydrogen and white oil raw materials are simultaneously fed into the hydrogenation reactor at a volume ratio of 750 to carry out the first-stage ...

Embodiment 3

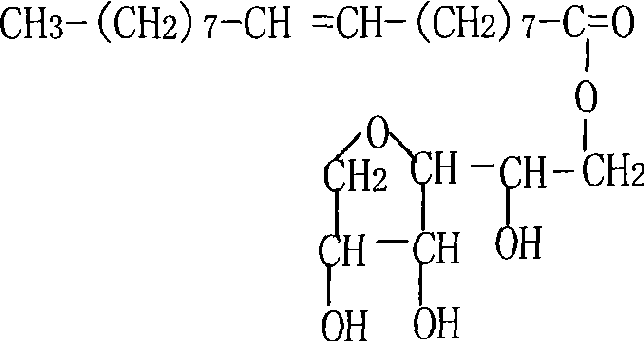

[0062] One, first prepare mannitol oleate

[0063] Take 40g mannitol in the same nitrogen or take 40g mannitol under nitrogen protection, dehydrate under the condition of 200 ℃ for 0.60 hours, then slowly add 100g oleic acid and 0.22g sodium hydroxide NaOH, constant temperature lipidation 3.5 hours, obtain the emulsifier of mannitol oleate, the structural formula of this mannitol oleate is identical with embodiment 1.

[0064] 2. Preparation of white oil for injection

[0065] 1. Preparation of raw materials

[0066] The paraffin-based oil is distilled by distillation, and the distilled fraction at 270-320°C is used as the raw material for white oil for injection.

[0067] 2. Remove impurities from raw materials

[0068] The hydrogen and white oil raw materials are simultaneously fed into the hydrogenation reactor at a volume ratio of 1000 to carry out the first-stage hydrogenation reaction. The hydrogen passes through the reaction bed in the hydrogen reactor and is separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com