Rebaudioside a composition and method for purifying rebaudioside a

A technology of steviolbioside and composition, applied in the field of steviolbioside A composition and its purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

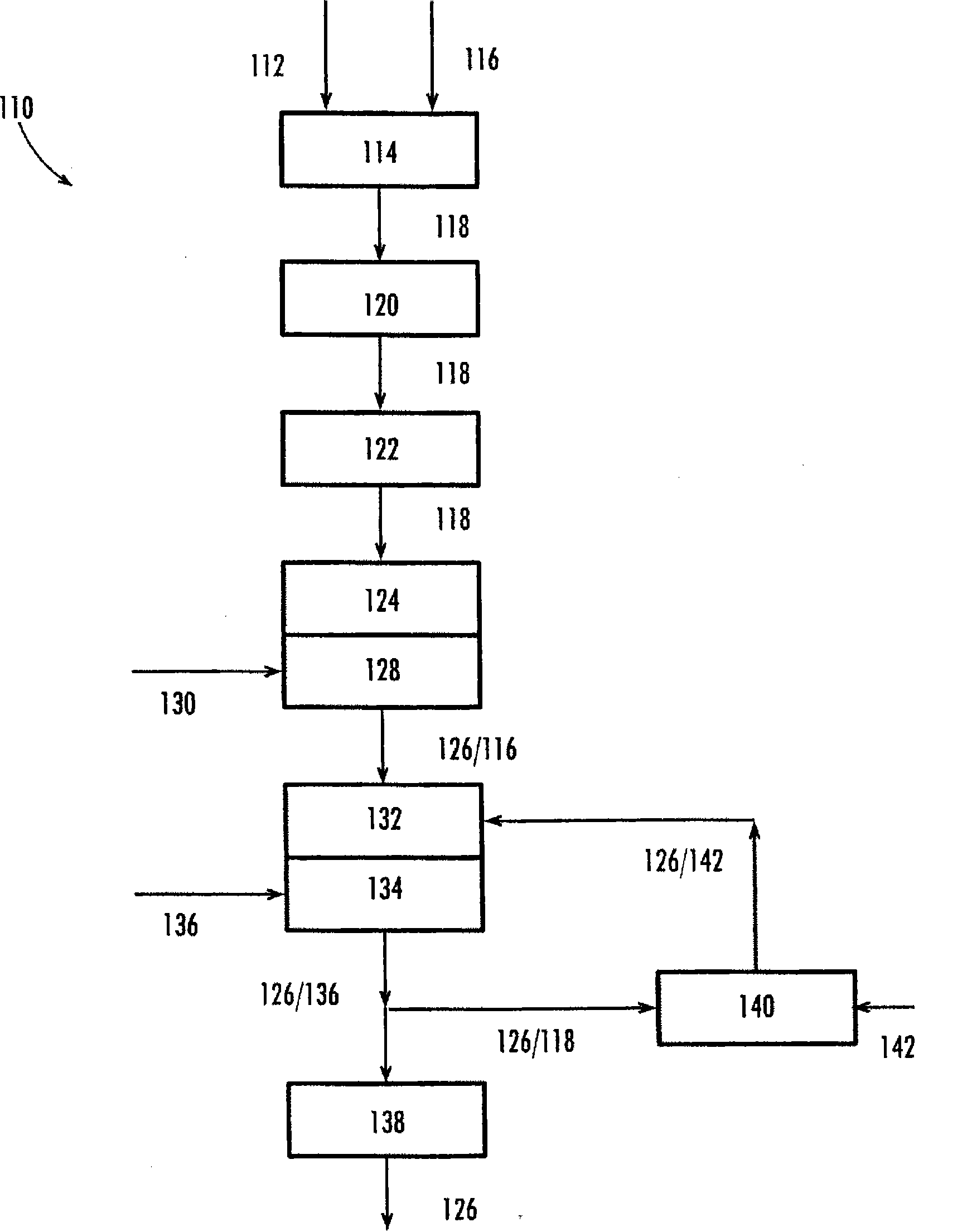

Method used

Image

Examples

Embodiment A1

[0080] The crude steviol glycoside A (77.4% purity) mixture was obtained from a commercial source. Impurities (6.2% steviol glycosides, 5.6% steviol diglycoside C, 0.6% steviol diglycoside F, 1.0% other steviol glycosides, 3.0% steviol diglycoside D, 4.9% steviol diglycoside B, 0.3% steviol diglycoside) In the dry state (water content of 4.7%), it was confirmed and quantified by HPLC.

[0081] Combine crude stevioside A (400g), ethanol (95%, 1200ml), methanol (99%, 400ml) and water (320ml) and heat to 50°C for 10 minutes. The clear solution was allowed to cool to 22°C for 16 hours. The white crystals were filtered and washed twice with ethanol (2×200 ml, 95%), and dried in a vacuum oven at low pressure (20 mm) at 50° C. for 16 to 24 hours.

[0082] The final composition (130 g) of the substantially pure steviol diglycoside A contains 98.91% steviol diglycoside A, 0.06% steviol diglycoside, 0.03% steviol diglycoside C, 0.12% steviol diglycoside F, and 0.13% other steviol glycosides ...

Embodiment A2

[0084] Crude stevioside A (80.37% purity) was obtained from commercial sources. Impurities (6.22% steviol glycosides, 2.28% steviol glycosides C, 0.35% steviol glycosides A, 0.78% steviol glycosides F, 0.72% other steviol glycosides, 3.33% steviol glycosides B, 0.07% steviol glycosides) In the dry state (moisture content 3.4%), it was confirmed and quantified by HPLC.

[0085] Combine crude stevioside A (100g), ethanol (95%, 320ml), methanol (99%, 120ml) and water (50ml) and heat to 30-40°C for 10 minutes. The clear solution was allowed to cool to 22°C for 16 hours. The white crystals were filtered and washed twice with ethanol (2×50 ml, 95%). The moist filter cake (88 g) was slurried in ethanol (95%, 1320 ml) for 16 hours, filtered, washed with ethanol (95%, 2×100 ml), and placed in a vacuum oven at low pressure (20 mm) 60 Dry at ℃ for 16 to 24 hours.

[0086] The final composition (72 g) of the substantially pure steviol diglycoside A contains 98.29% steviol diglycoside A, 0.03%...

Embodiment A3

[0088] Crude stevioside A (80.37% purity) was obtained from commercial sources. Impurities (6.22% steviol glycosides, 2.28% steviol glycosides C, 0.35% steviol glycosides A, 0.78% steviol glycosides F, 0.72% other steviol glycosides, 3.33% steviol glycosides B, 0.07% steviol glycosides) In the dry state (moisture content 3.4%), it was confirmed and quantified by HPLC.

[0089] Combine crude stevioside A (50g), ethanol (95%, 160ml), methanol (99%, 60ml) and water (25ml) and heat to about 30°C for 10 minutes. The clear solution was allowed to cool to 22°C for 16 hours. The white crystals were filtered and washed twice with ethanol (2×25 mL, 95%). The moist filter cake (40 g) was slurried in methanol (99%, 600 ml) for 16 hours, filtered, washed with methanol (99%, 2×25 ml), and placed in a vacuum oven at low pressure (20 mm) 60 Dry at ℃ for 16 to 24 hours.

[0090] The final composition (27.3 g) of the substantially pure steviol diglycoside A contains 98.22% steviol diglycoside A, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com