Method for processing resonance pole structure

A processing method and resonant column technology, applied in resonators, electrical components, circuits, etc., can solve the problems of high skill requirements of manufacturers, great influence on filter performance, long production cycle, etc., to achieve standardized design, easy Standardized design, the effect of less processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

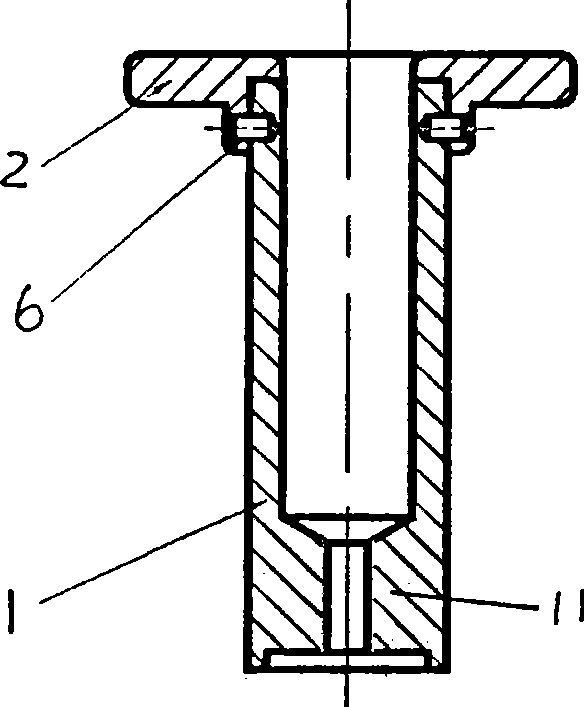

[0019] The processing method of the resonant column structure of the present invention is to use aluminum, steel, red copper or brass rods as raw materials to make a pipe body with a funnel-shaped connector at the bottom; to use aluminum, steel, red copper or brass rods as raw materials to manufacture into a flange; then connect the flange to the pipe body with pins to make a resonant column. A pin hole for connecting with a flange through a pin is provided on the periphery of the upper end of the pipe body. A ring edge for connecting with the pipe body is provided on the inner side of the flange, and a pin hole for connecting with the pipe body through a pin is provided on the ring edge. Pins are standard parts.

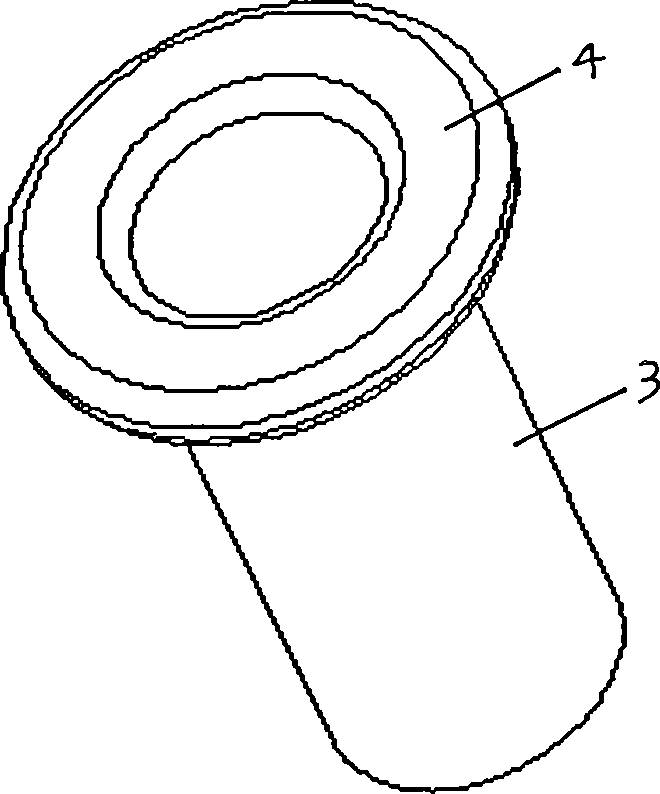

[0020] The three-dimensional structure of the resonance column made by the method of the present invention is as follows: image 3 As shown, it includes a pipe body 1, an upper flange 2, and a funnel-shaped connecting piece 3 for inserting a countersunk screw to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com