Control method for digital high voltage sodium lamp electronic ballast

A technology for electronic ballasts and high-pressure sodium lamps, which is applied in the control field of digital electronic ballasts, can solve the problems of large program volume, complex program, and poor readability, and achieve the goal of less program volume, simple program, and reduced vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The present invention will be further described below in conjunction with the accompanying drawings of the description.

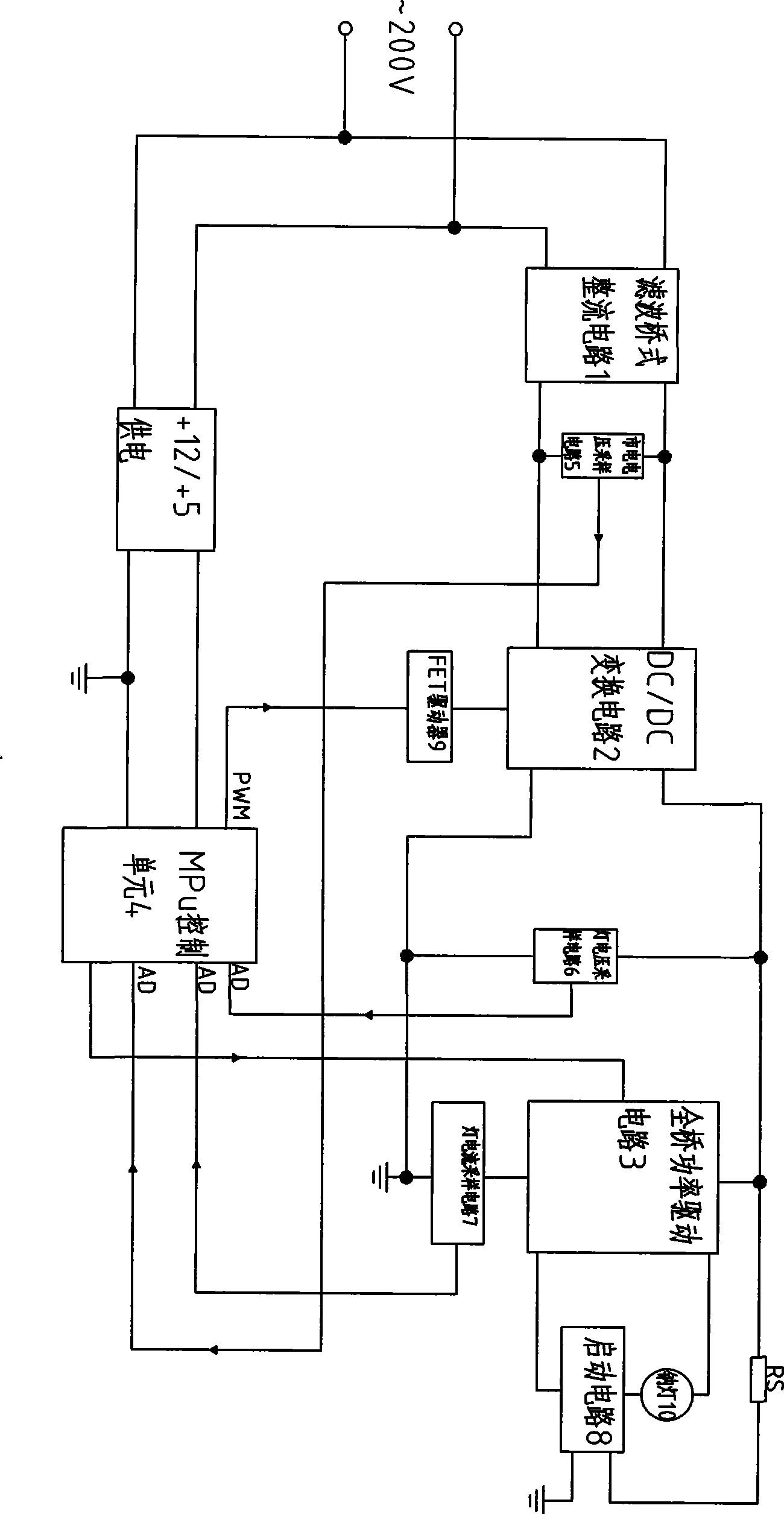

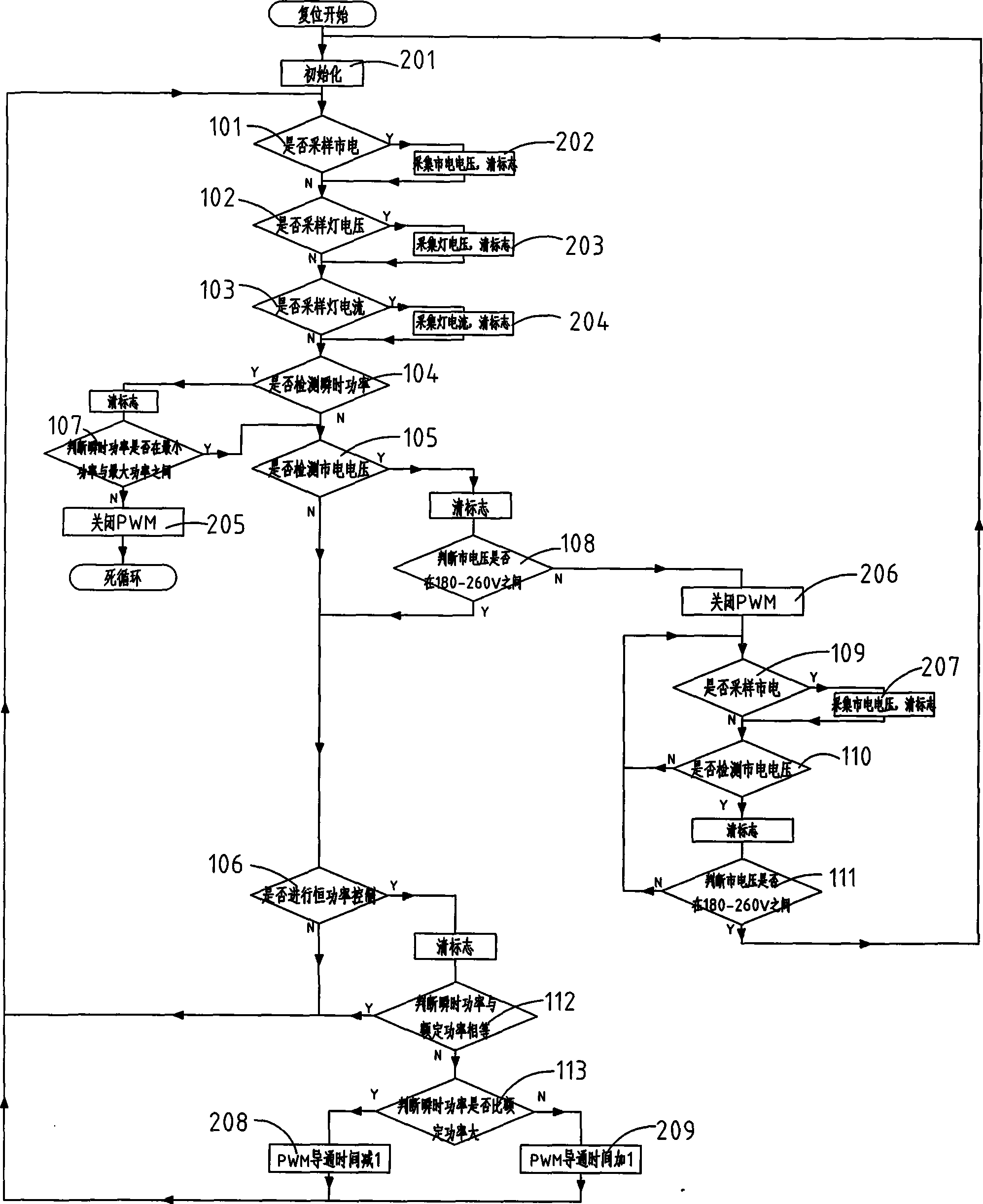

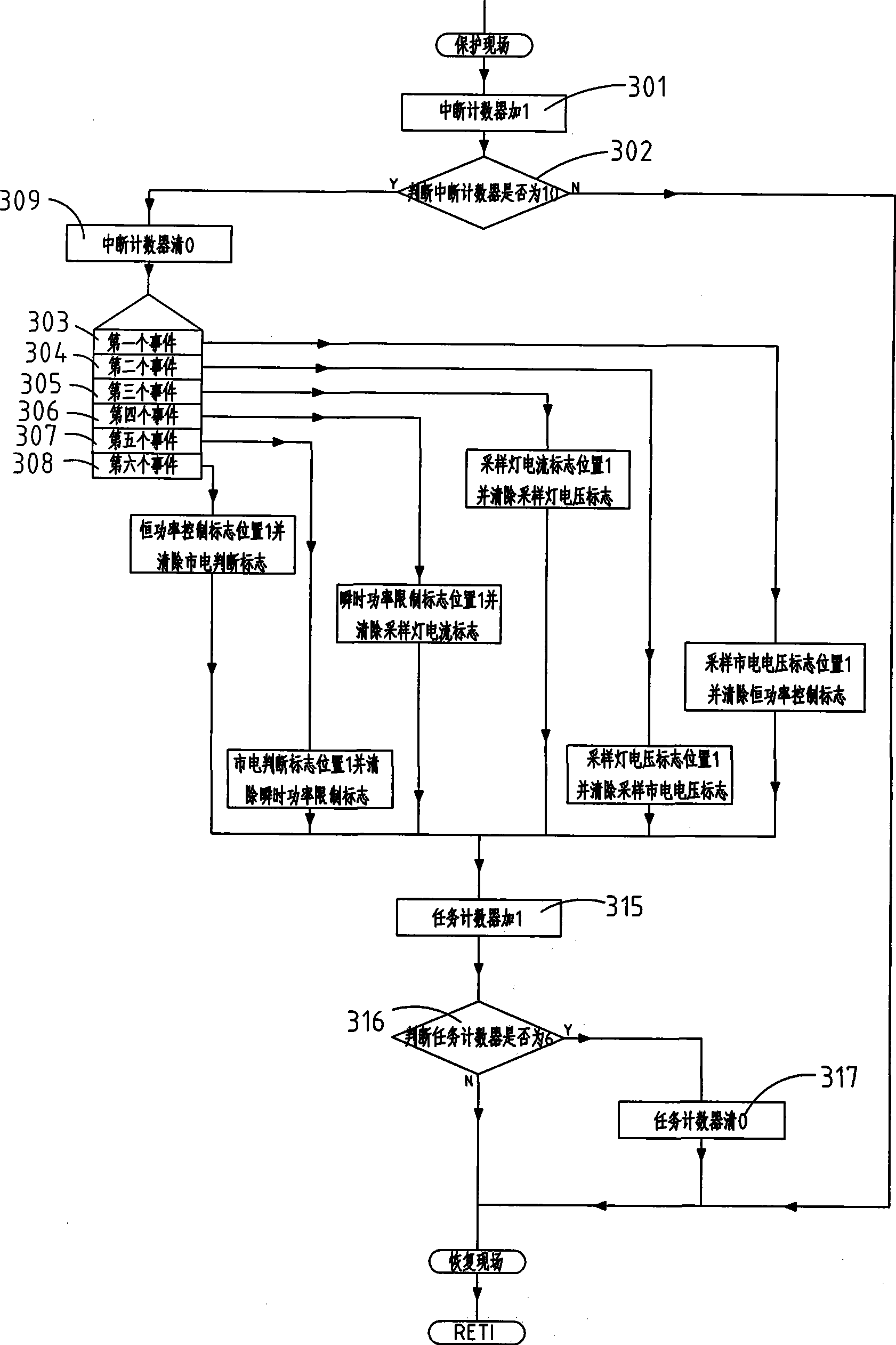

[0032] Such as figure 1 As shown, the circuit of a digital high-pressure sodium lamp electronic ballast control method of the present invention includes a filter bridge rectifier circuit 1, a DC / DC conversion circuit 2, a starting circuit 8, a full-bridge power drive circuit 3 and a main frequency of 20MHz The MPU control unit 4 . The input terminal of the DC / DC conversion circuit 2 is connected to the output terminal of the filter bridge rectifier circuit 1 , and the filter bridge rectifier circuit 1 rectifies the AC mains to obtain the DC voltage required by the DC / DC conversion circuit 2 . The output end of the DC / DC conversion circuit 2 is connected with a starting circuit 8, and the starting circuit 8 is directly connected with the high-pressure sodium lamp 10; the rectified DC voltage is supplied to the starting circuit 8 after DC / DC conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com