Automatic packaging machine and method for optical fiber ceramic ferrule metal component

A ceramic ferrule and packaging machine technology, which is applied in metal processing, metal processing equipment, optical waveguide coupling, etc., can solve the problems of low efficiency and difficult control of precision in manual operation and assembly, achieve stable downforce and improve finished products The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

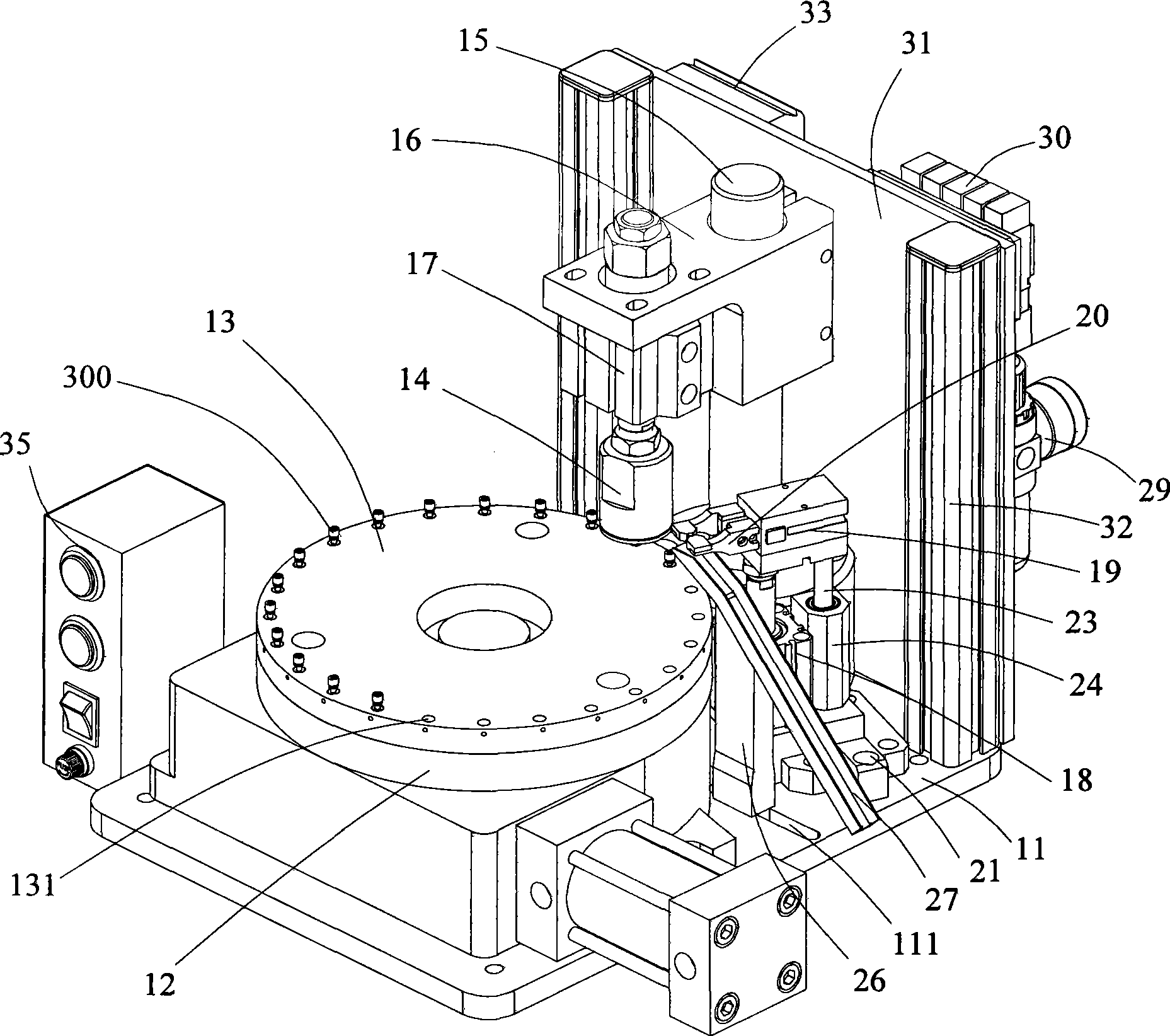

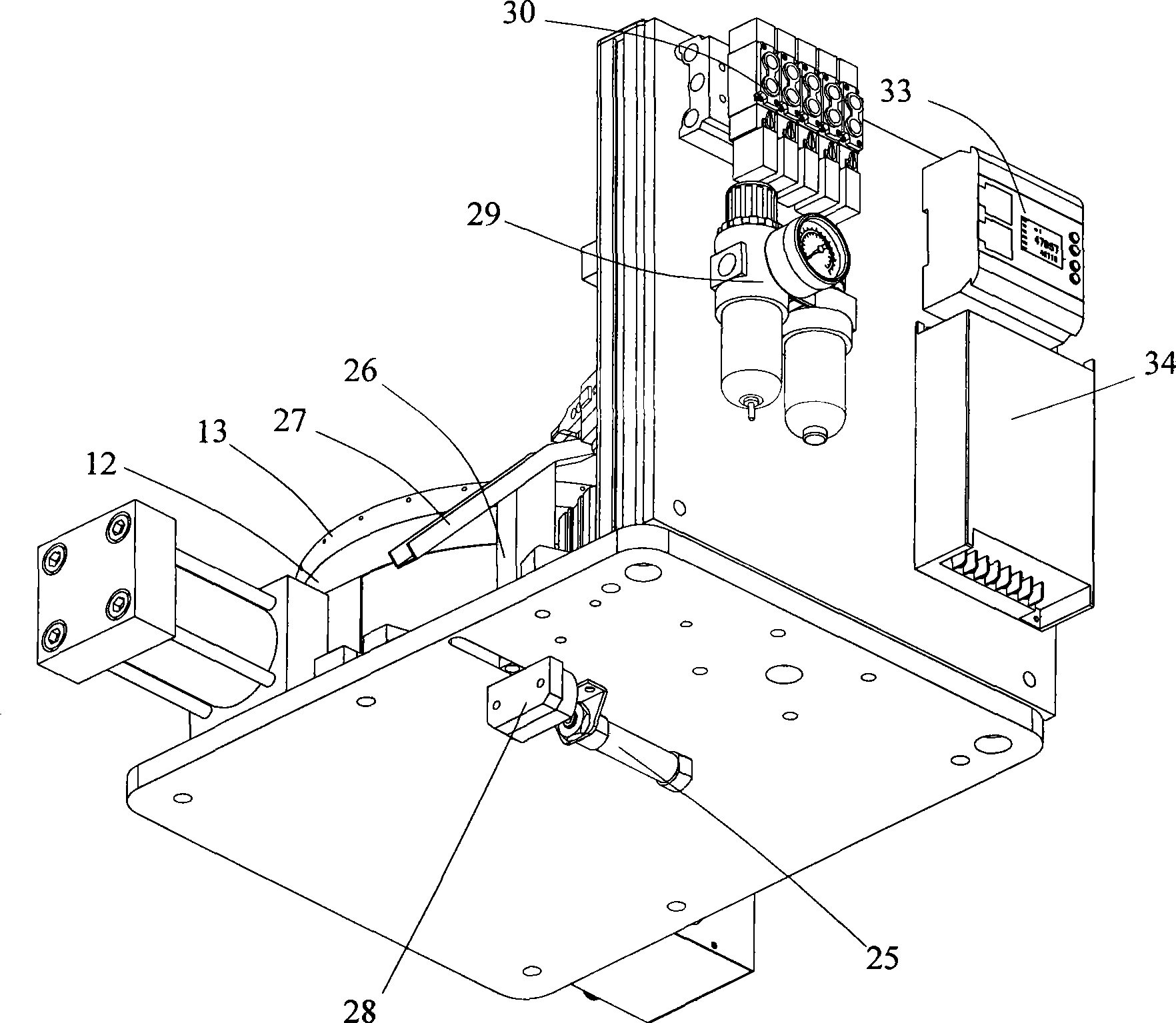

[0027] Such as Figure 1 to Figure 3 Shown is a specific embodiment of the automatic packaging machine of the present invention, which is used for automatic packaging of the optical fiber ceramic ferrule metal assembly 300 . The automatic packaging machine includes a base 11, an indexing turntable 12 installed on the base 11 and a pressing device, a workpiece positioning ring 13 installed on the indexing turntable 12, and a control device for controlling the cooperation between the indexing turntable 12 and the pressing device .

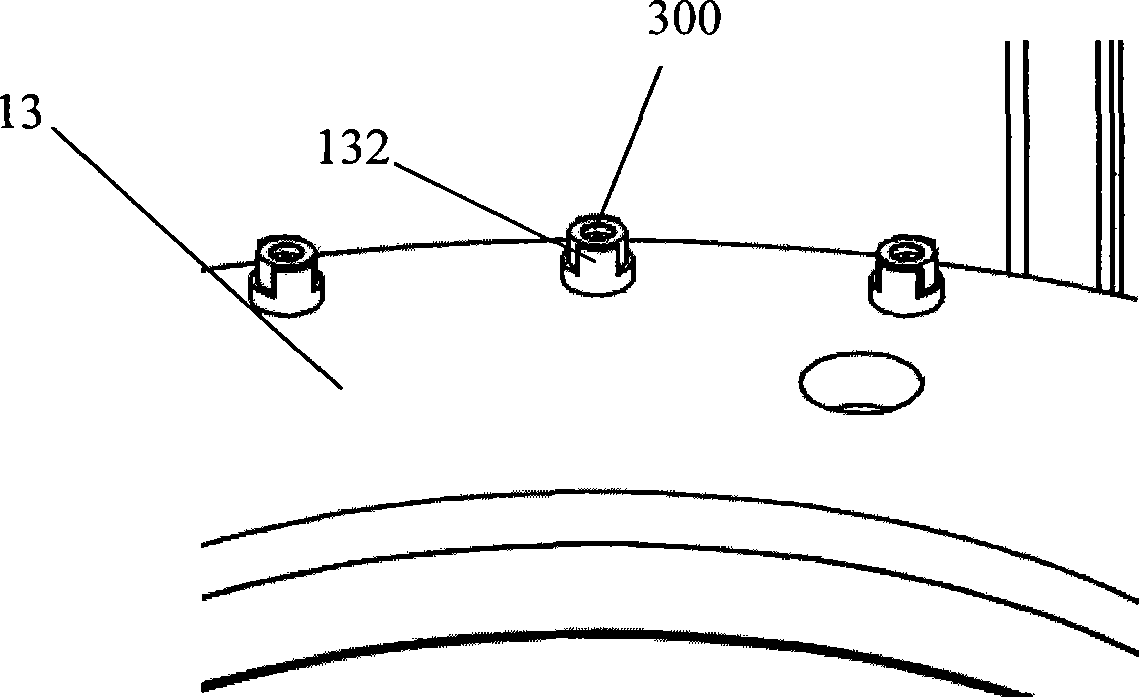

[0028] A plurality of workpiece mounting positions 131 are provided on the circumference of the workpiece positioning ring 13 for placing the belt assembly workpiece. The workpiece mounting positions 131 are evenly distributed on the workpiece positioning ring 13 . When the indexing turntable 12 is working, the workpiece positioning ring 13 is driven to rotate to set the angle, so that the workpiece mounting position 131 is rotated to the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com