Tension measurement and control device of beam dyeing machine

A control device and jigger technology, applied in the field of textile printing and dyeing, can solve the problems of unstable cloth tension, deep color, light dyeing color, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

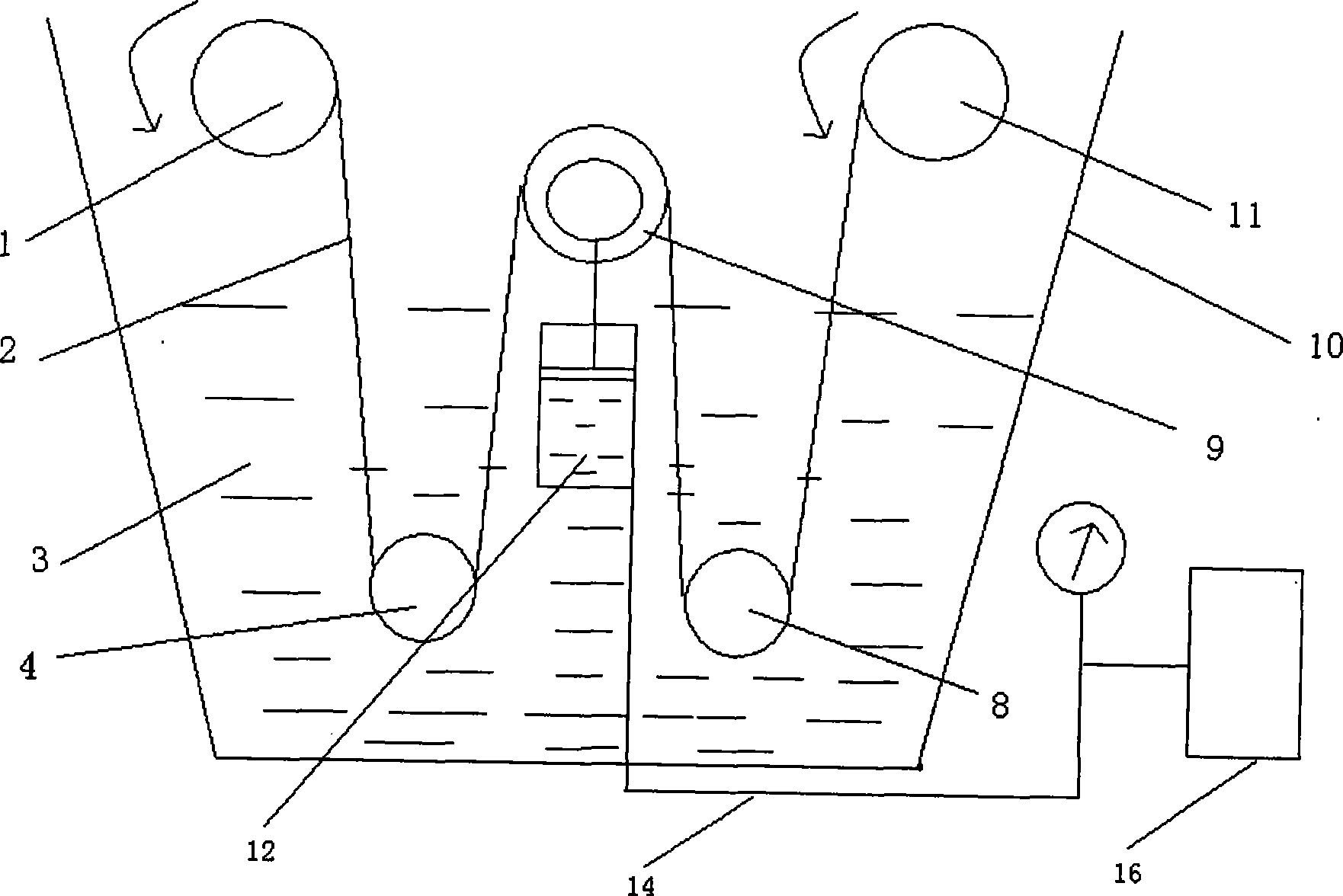

[0009] The present invention will be further described below in conjunction with accompanying drawing. figure 1 It is a measurement and control principle diagram of the tension measurement and control device of the dyeing jigger of the present invention; figure 2 It is a schematic diagram of the hydraulic cylinder and force measuring roller mechanism of the present invention.

[0010] A tension measurement and control device for a dyeing jigger provided by the present invention includes a casing 10 for containing the dye liquor 3, the first cloth winding roller 1 and the second cloth winding roller 11 are located above the dye liquor 3, and are respectively connected with a The variable frequency motor that can control its rotational speed and torque is connected. The first lower road roller 4 and the second lower road roller 8 are located inside the dye liquor 3. It is characterized in that: it also includes a The force-measuring roller 9 between the rollers 8, the force-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com