Preparing technology of environment protection type butyronitrile / polychloroethylene blended rubber

A polyvinyl chloride and environment-friendly technology, which is applied in the preparation field of environment-friendly nitrile-butadiene/polyvinyl chloride blended rubber, can solve the problems of unenvironmental protection, toxicity and harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

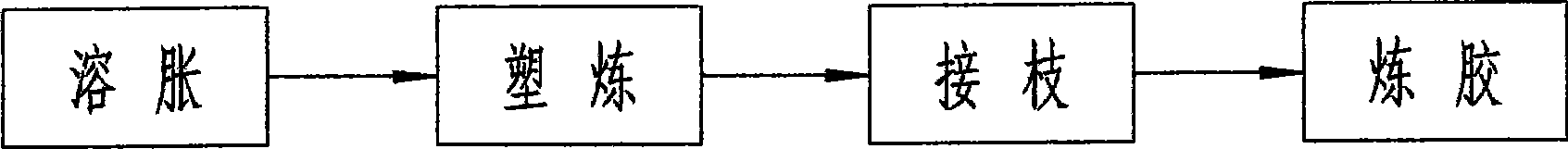

Image

Examples

Embodiment

[0011] Product name: Environmentally friendly nitrile / polyvinyl chloride blended rubber

[0012] Formula: formula unit is weight percentage

[0013] Rubber raw material: 37.78% of nitrile rubber;

[0014] Plastic raw material: polyvinyl chloride resin 18.89%;

[0015] Reinforcing agent: 11.33% of quick-pressed furnace black, 11.33% of non-polluting high-definition semi-reinforced furnace black, and 1.89% of Coumarone resin;

[0016] Plasticizer: Dioctyl phthalate 9.83%, of which, the first part is 5.67% and the second part is 4.16%;

[0017] Active agent: light magnesium oxide 1.89%, zinc oxide 1.51%, stearic acid 0.68%;

[0018] Antiaging agent: 0.57% of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.38% of 2-mercaptobenzimidazole;

[0019] Comprehensive additives: epoxy soybean oil 1.13%, barium stearate 0.57%, zinc stearate 0.57%;

[0020] Vulcanizing agent: sulfur 0.15%, dicumyl peroxide 0.94%;

[0021] Accelerator: dibenzothiazole disulfide 0.57%;

[0022] prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com