Procedure for the preparation and cleaning of tools used for manufacturing composite material components, and the corresponding device

A technology for synthetic materials and tools, applied in the direction of cleaning methods and utensils, chemical instruments and methods, and devices for coating liquids on surfaces, etc., to achieve the effects of reducing the risk of tool damage, avoiding tool corrosion, and eliminating the accumulation of anti-sticking agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

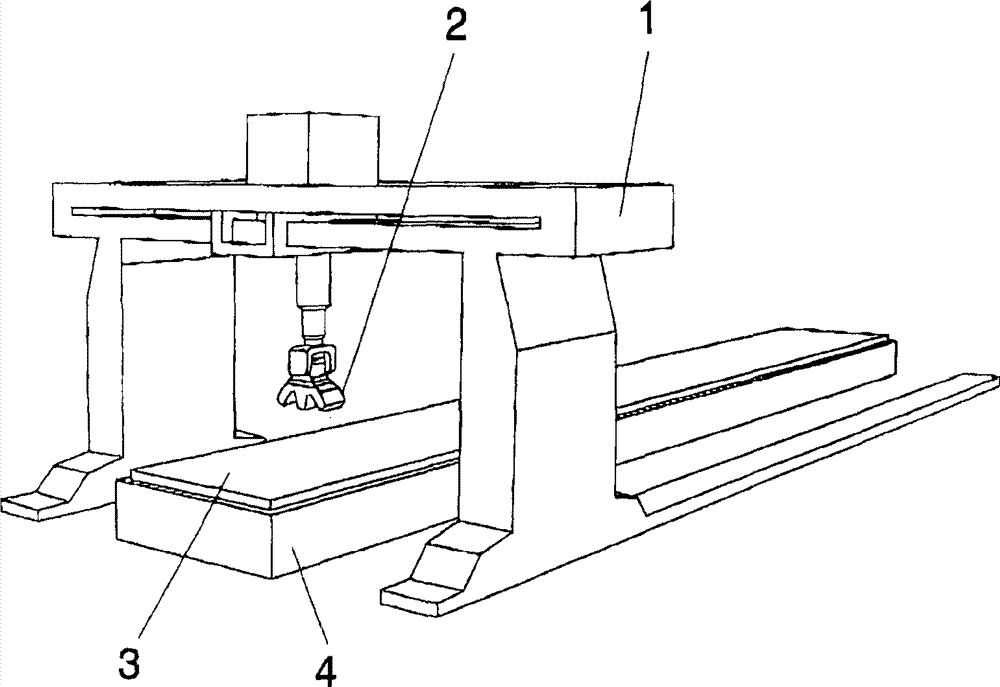

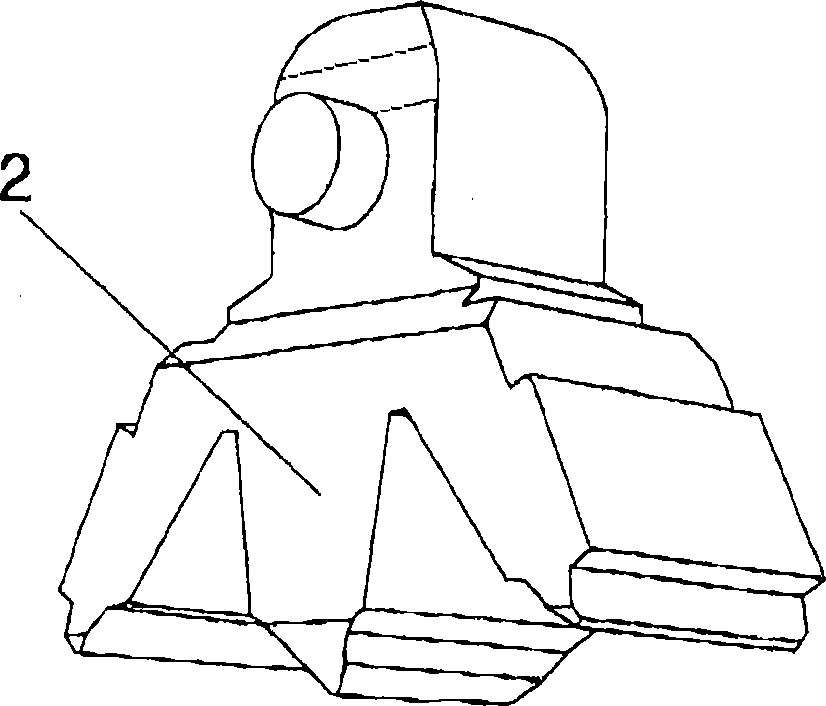

[0029] The following is a description of one embodiment of the invention. Numbers refer to those used in the figures.

[0030] According to an example of the invention, the method for preparing and cleaning tools for the manufacture of components in synthetic materials is suitable for moulds, stock, angles and modules mainly used for the manufacture of components for the aviation industry.

[0031] The method used in the present invention involves four automated stages, including:

[0032] a first stage of blowing and suction in which the surface resin layer is removed from said tool;

[0033] The second stage of laser and suction cleaning by means of the tool (3) on the positioner (4) being held under the laser head so that all surfaces and recesses to be cleaned are cleaned by the laser;

[0034] A third stage comprising the application of anti-blocking agent on the tool (3) by spraying;

[0035] A fourth stage in which dry release agent from the laser head of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com