Photocatalyst for degrading organic pollutant and preparation method thereof

A technology of organic pollutants and photocatalysts, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of large-scale application, low solar energy utilization, Problems such as limitations in the scope of use, to achieve high commercial application prospects, high ability to absorb visible light, and the effect of not harsh application conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

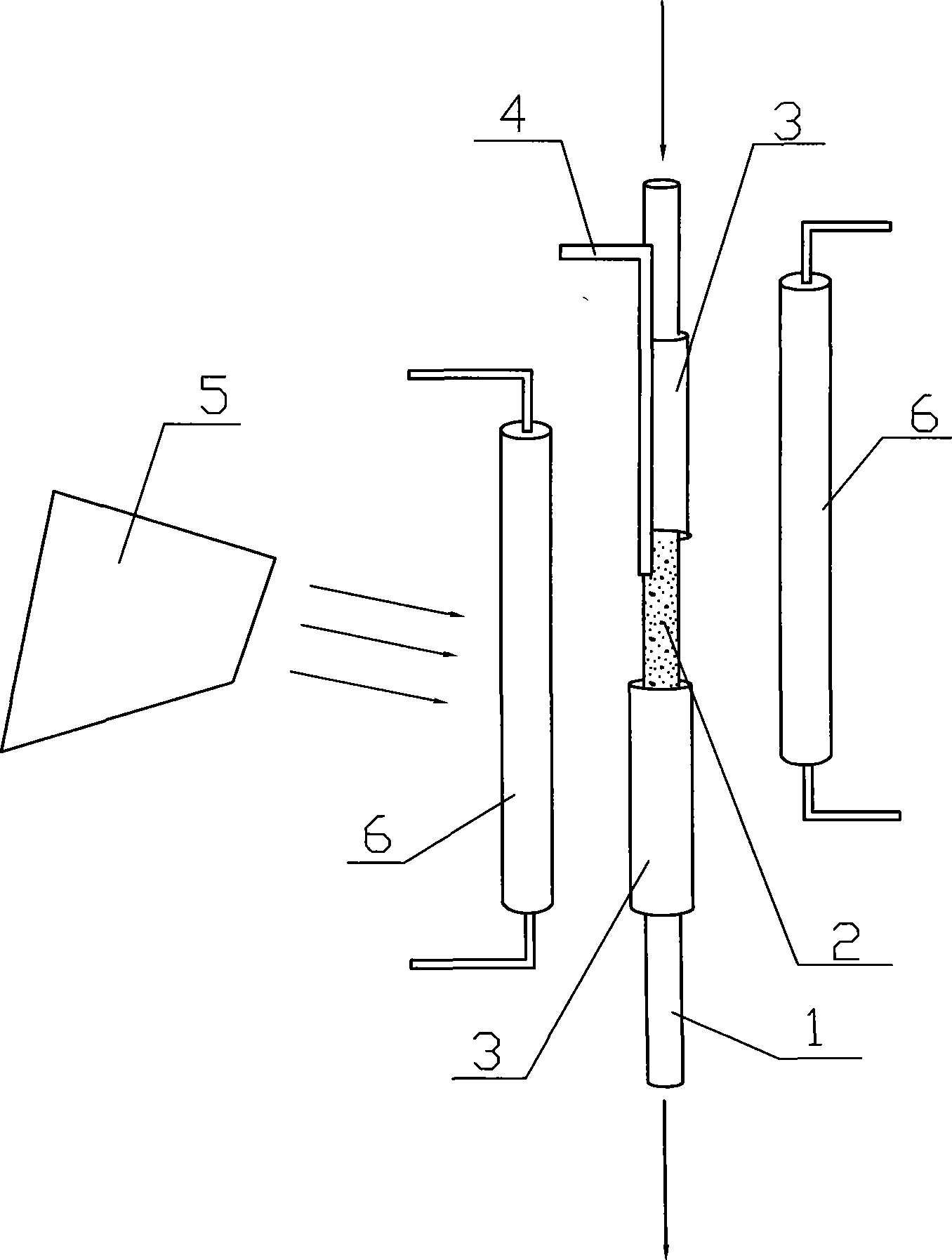

Method used

Image

Examples

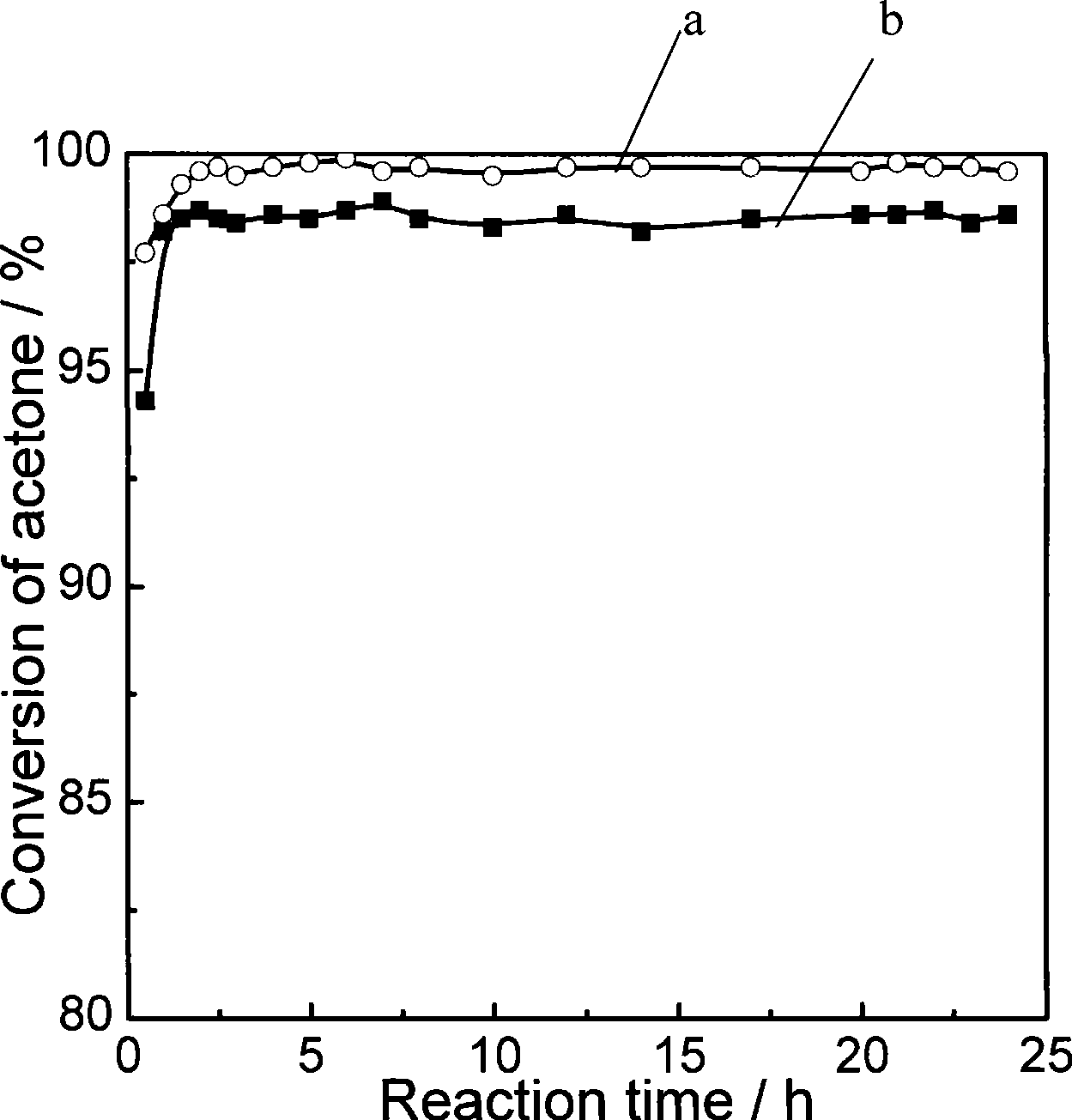

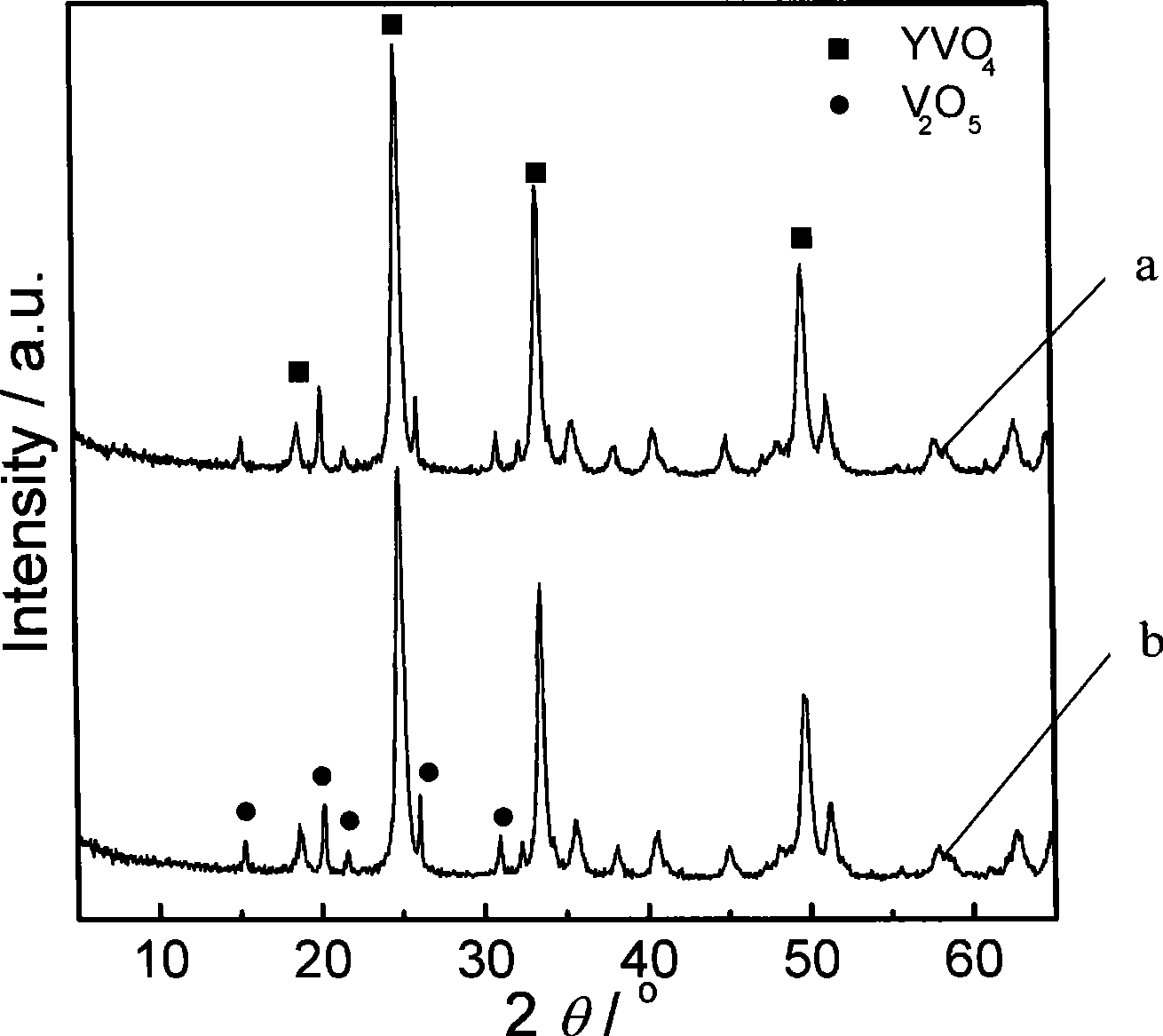

Embodiment 1

[0020] Weigh 0.777g of ammonium metavanadate, add 50ml of deionized water, stir and dissolve in an 80°C water bath, and obtain an ammonium metavanadate solution. Weigh 2.50 g of yttrium oxide, add 5 ml of concentrated nitric acid and 7 ml of deionized water, stir and dissolve in a water bath at 80° C. to obtain a yttrium nitrate solution. Then slowly drop the yttrium nitrate solution into the ammonium metavanadate solution under the condition of stirring to form a yellow precipitate, stir and age for 2 hours and then remove the water in the solution by rotary evaporation, and the obtained solid is dried in an oven at 90°C Dry, and finally bake in a muffle furnace at 500°C for 4 hours. After natural cooling, the V prepared by precipitation method was obtained. 0.3 Y 1 o 2.25 catalyst.

Embodiment 2

[0022] Weigh 1.657g of ammonium metavanadate, add 50ml of deionized water, stir and dissolve in an 80°C water bath, and obtain an ammonium metavanadate solution. Weigh 2.0 g of yttrium oxide, add 4 ml of concentrated nitric acid and 7 ml of deionized water, stir and dissolve in a water bath at 80° C. to obtain a yttrium nitrate solution. Then slowly drop the yttrium nitrate solution into the ammonium metavanadate solution under the condition of stirring to form a yellow precipitate, stir and age for 2 hours, then remove the water in the solution by rotary evaporation, and dry the obtained solid in an oven at 90°C , and finally baked in a muffle furnace at 500°C for 4 hours. After natural cooling, the V prepared by precipitation method was obtained. 0.8 Y 1 o 3.5 catalyst.

Embodiment 3

[0024] Weigh 1.554 g of ammonium metavanadate, add 60 ml of deionized water, stir and dissolve in a water bath at 80° C., and obtain an ammonium metavanadate solution. Weigh 1.50 g of yttrium oxide, add 3 ml of concentrated nitric acid and 8 ml of deionized water, stir and dissolve in a water bath at 80° C. to obtain a yttrium nitrate solution. Then slowly drop the yttrium nitrate solution into the ammonium metavanadate solution under the condition of stirring to form a yellow precipitate, stir and age for 2 hours, then remove the water in the solution by rotary evaporation, and dry the obtained solid in an oven at 90°C , and finally baked in a muffle furnace at 500°C for 4 hours. After natural cooling, the V prepared by precipitation method was obtained. 1 Y 1 o 4 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com