Liquid crystal display panel, liquid crystal display device and method for manufacturing liquid crystal display panel

A liquid crystal display panel and display area technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of display image quality error, increase in proportion, increase in hygroscopicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

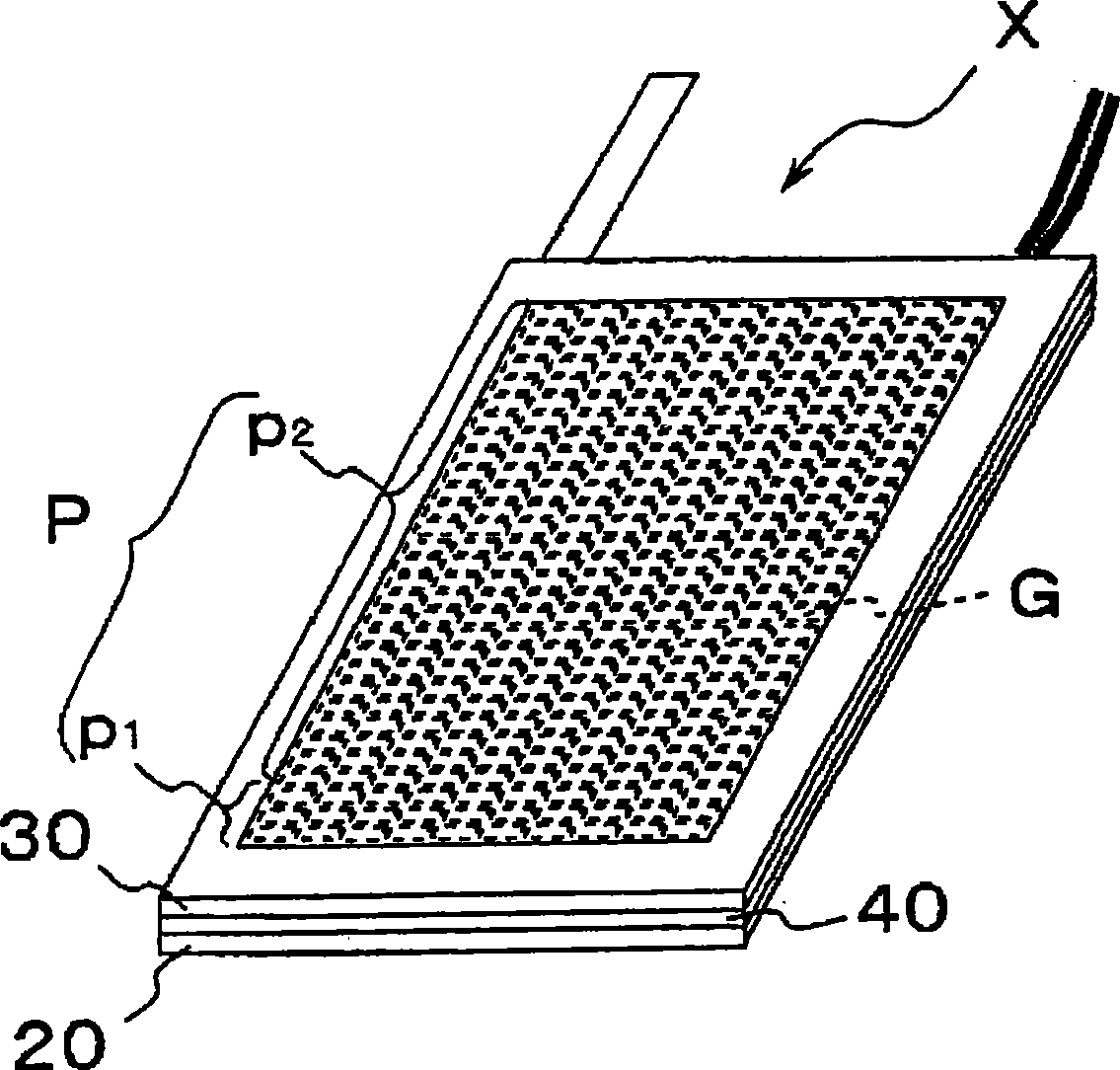

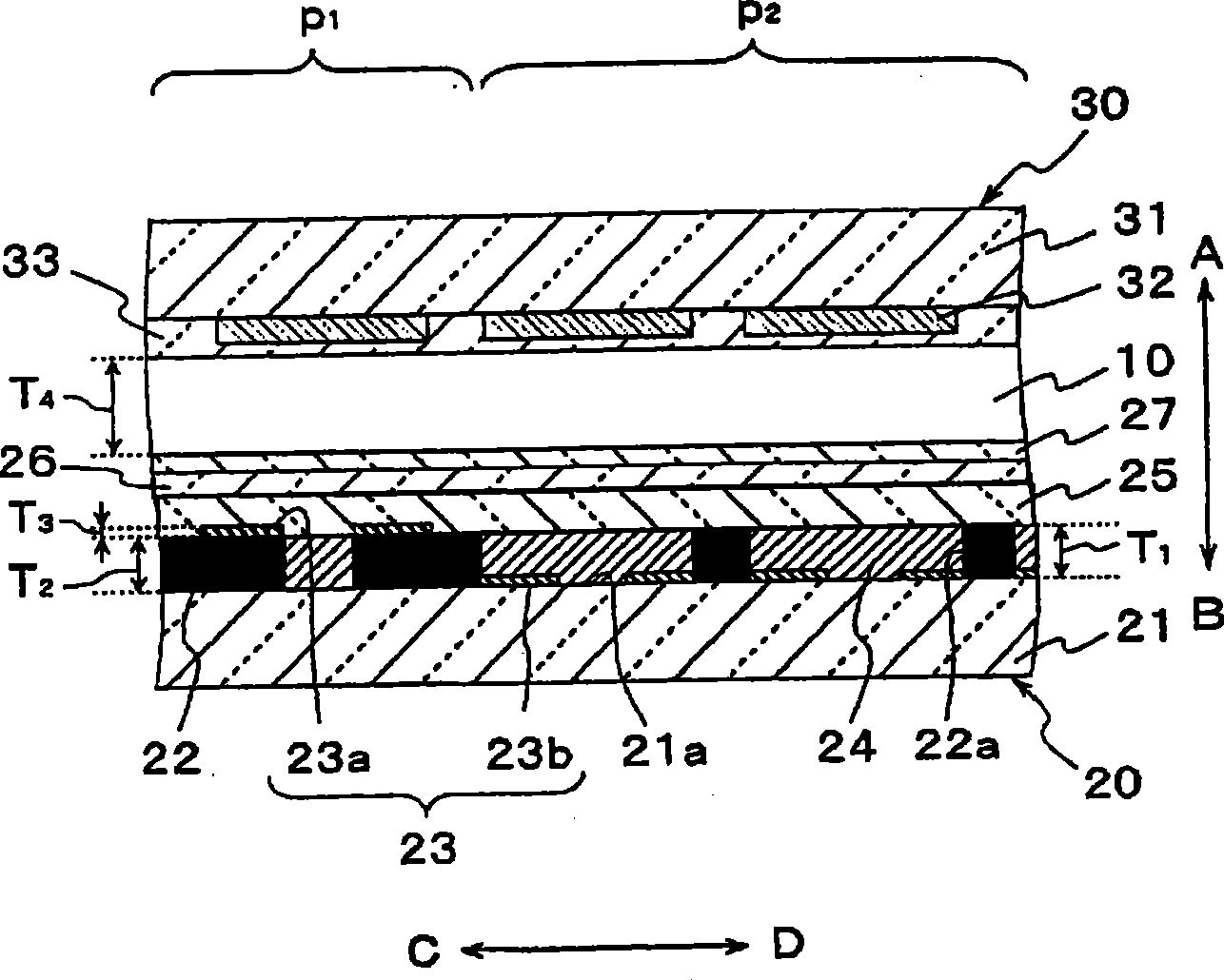

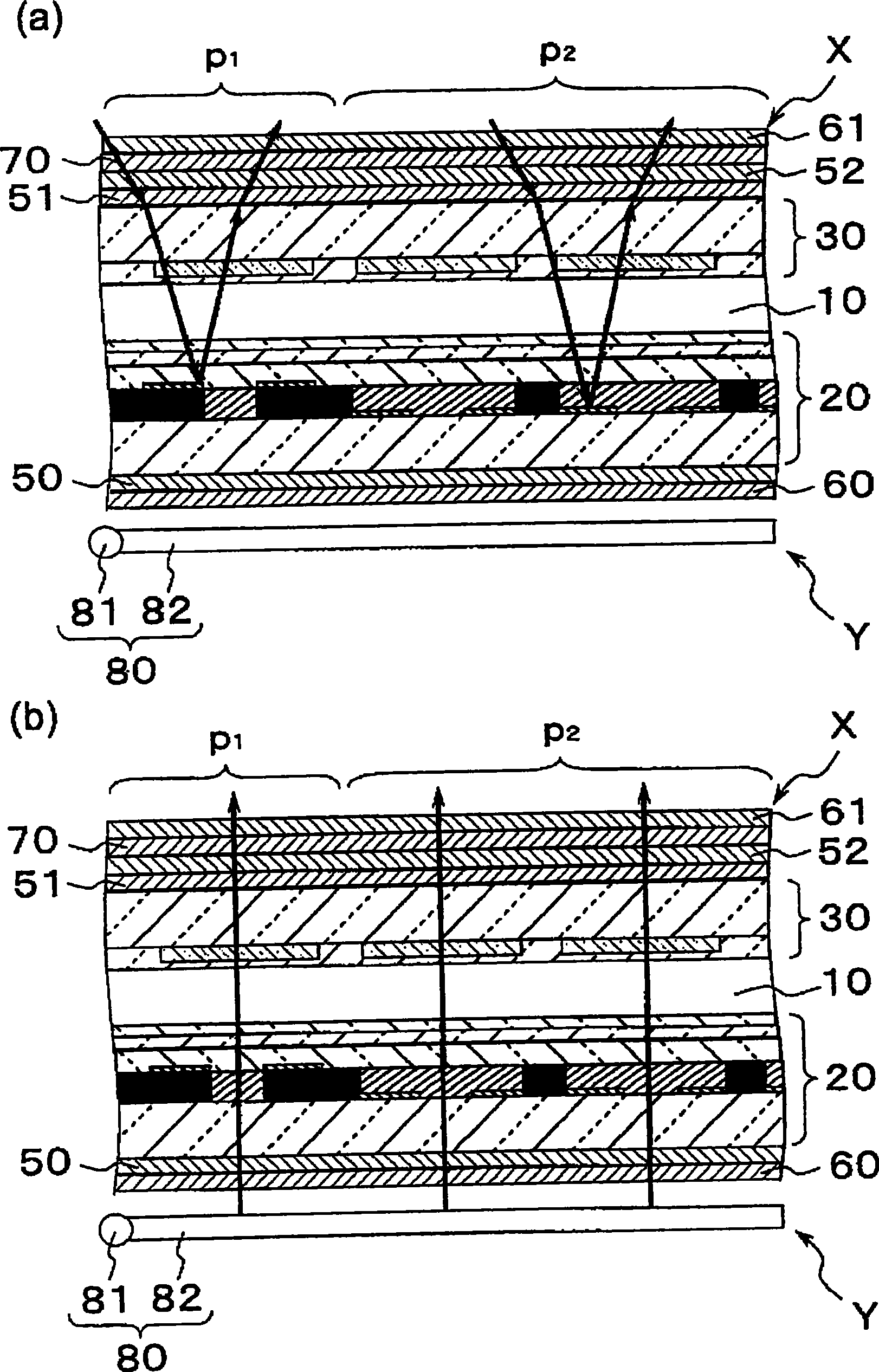

[0052] figure 1 It is a perspective view showing a schematic configuration of a transflective liquid crystal display panel X according to an embodiment of the present invention. figure 2 Yes figure 1 An enlarged cross-sectional view of main parts of the liquid crystal display panel X shown.

[0053] The liquid crystal display panel X includes a liquid crystal layer 10, a first base 20, a second base 30, and a sealing member 40. By interposing the liquid crystal layer between the first base 20 and the second base 30, the liquid crystal layer 10 is sealed by the sealing member 40. , thereby forming a display area P including a plurality of pixels G for displaying images.

[0054] The liquid crystal layer 10 exhibits electronic, optical, mechanical, or magnetic anisotropy, and is a layer composed of liquid crystals that have both solid regularity and liquid fluidity. As the liquid crystal, nematic liquid crystal, color-changing liquid crystal, smectic liquid crystal, etc. are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com