Battery casing and manufacturing process for the battery

A technology of a battery case and a manufacturing method, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of inability to connect well, peel off, and the lead plate is not easy to melt, so as to improve production efficiency and increase capacity. , high consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A method for making an aluminum alloy battery, comprising the step of making a case, the step of making the case further includes the following steps:

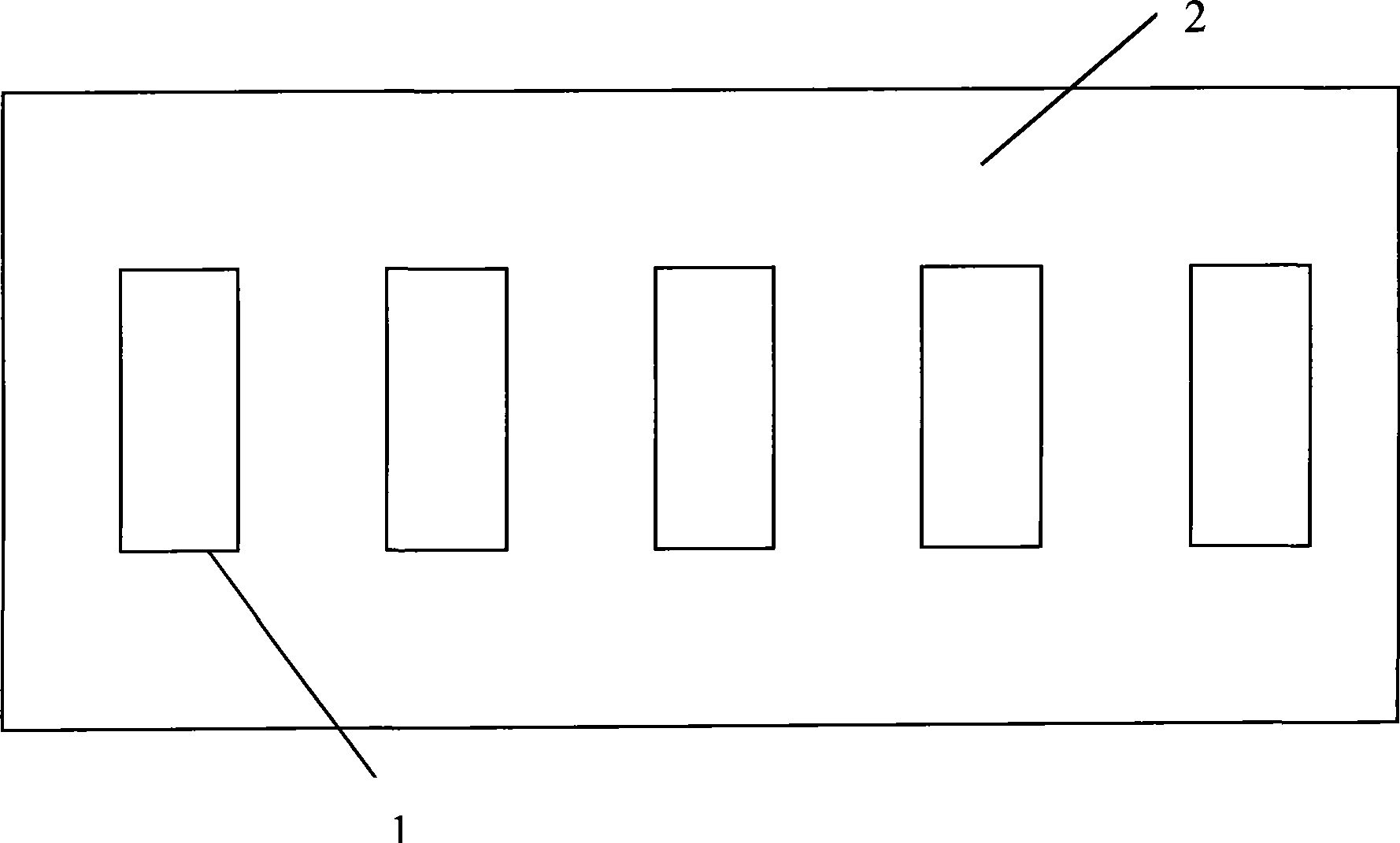

[0021] Such as figure 1 As mentioned above, using the CA heat compounding method (that is, controlled atmosphere heat compounding), the CA heat compounding temperature is 550±50°C, and according to the size requirements of the aluminum alloy shell to be produced, a small piece of nickel with a thickness of 0.1mm The strips 1 are respectively compounded on the 3-series aluminum alloy plate 2 with a thickness of 0.6mm, so that each section of the nickel strip 1 and the aluminum alloy plate 2 form a uniform monomer;

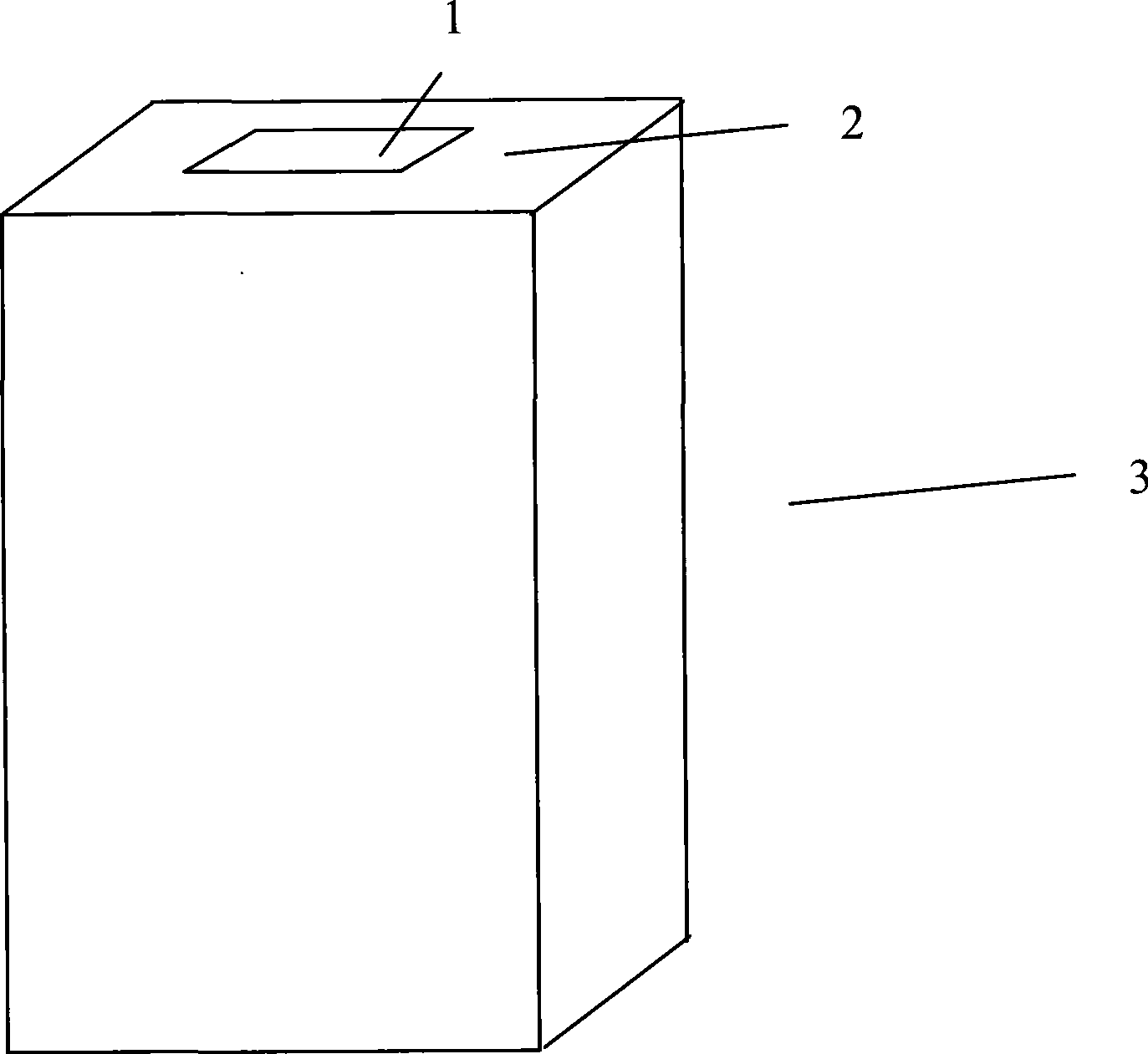

[0022] According to the size requirements of the aluminum alloy shell to be produced, the aluminum alloy plate 2 compounded with the nickel strip 1 is cut and punched into figure 2 The aluminum alloy casing 3 shown, the stamping here is that described nickel strip 1 is stamped on the bottom of the aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com