Imaging lens unit and camera module

A camera lens and lens technology, applied in electrical components, image communication, optical components, etc., can solve the problem of inability to shoot high-quality images, and achieve the effects of high image quality and shortened optical length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

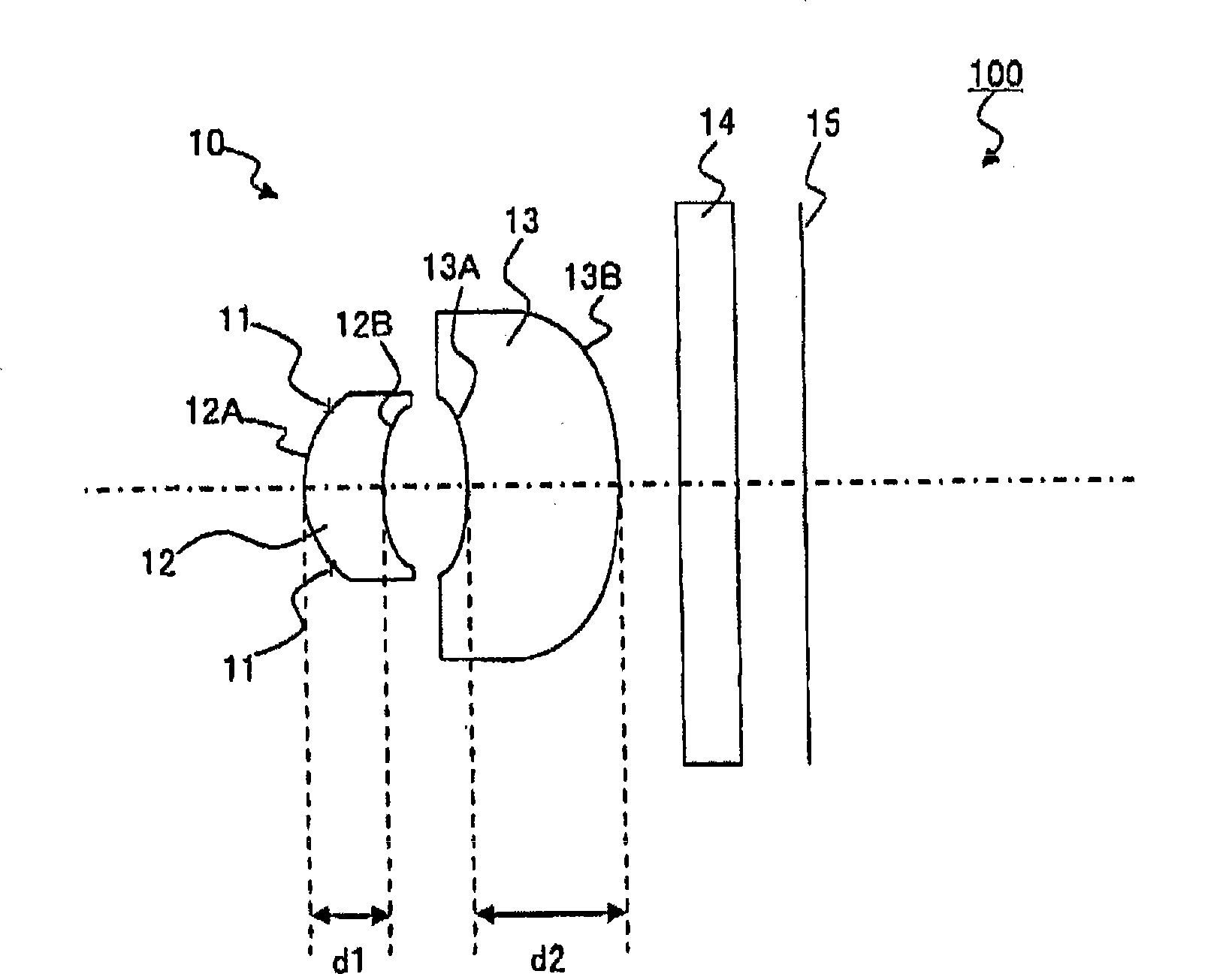

[0064] Next, Embodiment 1 of the present invention will be described. Figure 5 A side view of the camera module 101 according to the first embodiment is schematically shown. again, in Figure 5 Among them, the variable diaphragm 11 from the object side is used as ST (stop (stop) surface), the object side lens surface 12A of the first lens 12 is used as the second surface, and the imaging side of the first lens 12 is The lens surface 12B is used as the 3rd surface, the object side lens surface 13A of the second lens 13 is used as the 4th surface, the imaging side lens surface 13B of the second lens 13 is used as the 5th surface, and the object-side lens surface 13A of the cover glass 14 is used as the 5th surface. The side surface is defined as the sixth surface, the imaging side surface of the cover glass 14 is defined as the seventh surface, and the imaging surface of the imaging element 15 is defined as the eighth surface. In addition, in this embodiment, resin is used fo...

Embodiment 2

[0081] Next, Embodiment 2 of the present invention will be described. Figure 7 It is a side view schematically showing the camera module 102 according to the second embodiment. Again, if Figure 7 As shown, in the camera module 102 of the second embodiment, the configuration other than the first lens 22 and the second lens 23 is substantially the same as that of the camera module 101 of the first embodiment. Accordingly, substantially the same structures are marked with the same symbols, and descriptions thereof are omitted. In addition, in this embodiment, resin is used for both the first lens 22 and the second lens 23 as lens materials, but glass may also be used.

[0082] Again, the same as in Example 1, in Figure 7 Among them, the light amount iris diaphragm 11 is referred to as ST (stop surface) from the object side, the object-side lens surface 22A of the first lens 22 is used as the second surface, and the imaging-side lens surface 22B of the first lens 22 is As t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com