Mold for crack-containing bolting test

A technology of cracks and molds, which is applied in the field of molds with cracks and anchor tests, can solve the problems of inability to effectively simulate the effect of anchor rods on crack reinforcement and crack prevention, the cumbersome process of making test specimens, and the inability to firmly fix anchor rods, etc. Achieve the effect of simple structure, low cost and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

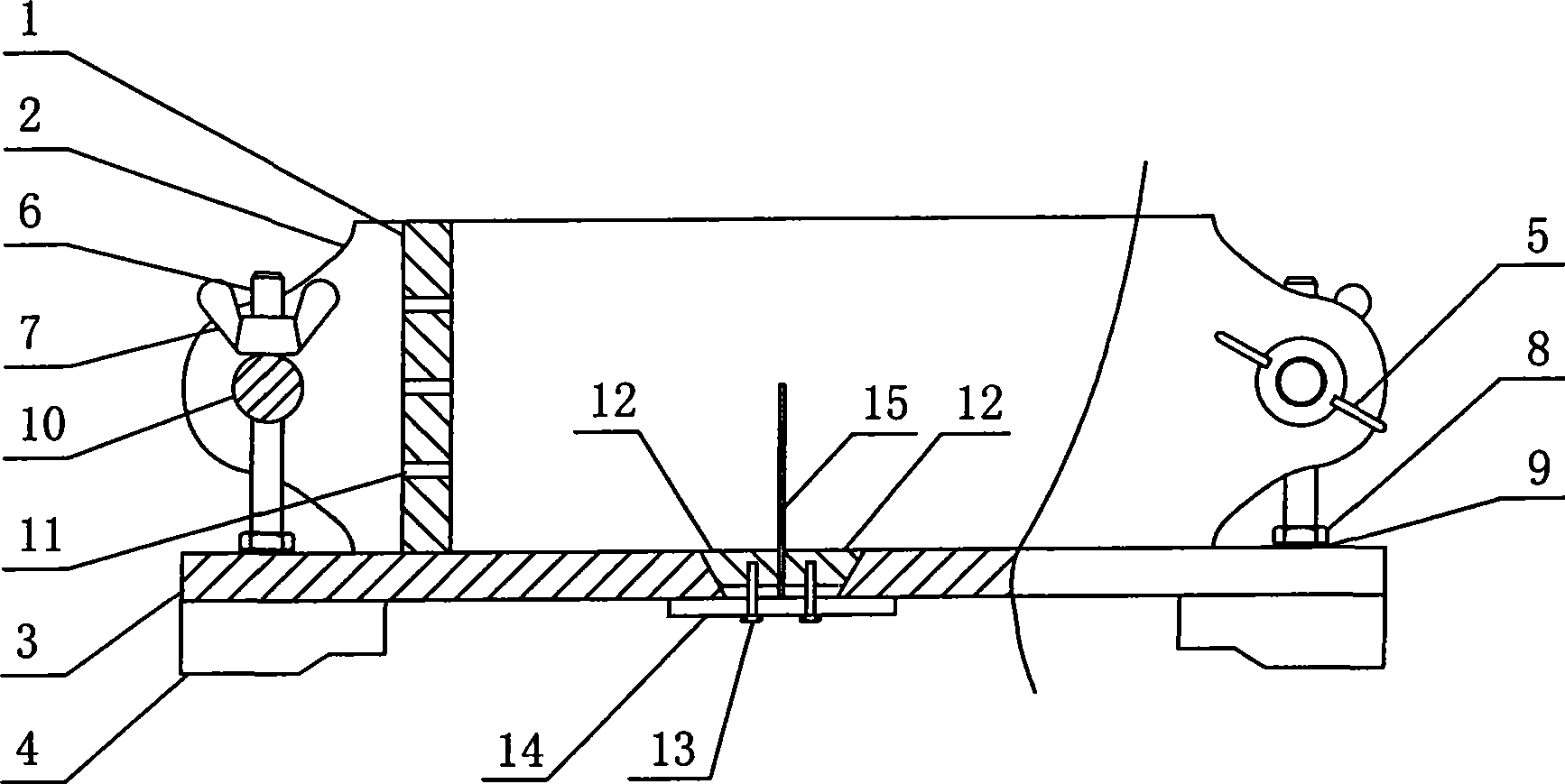

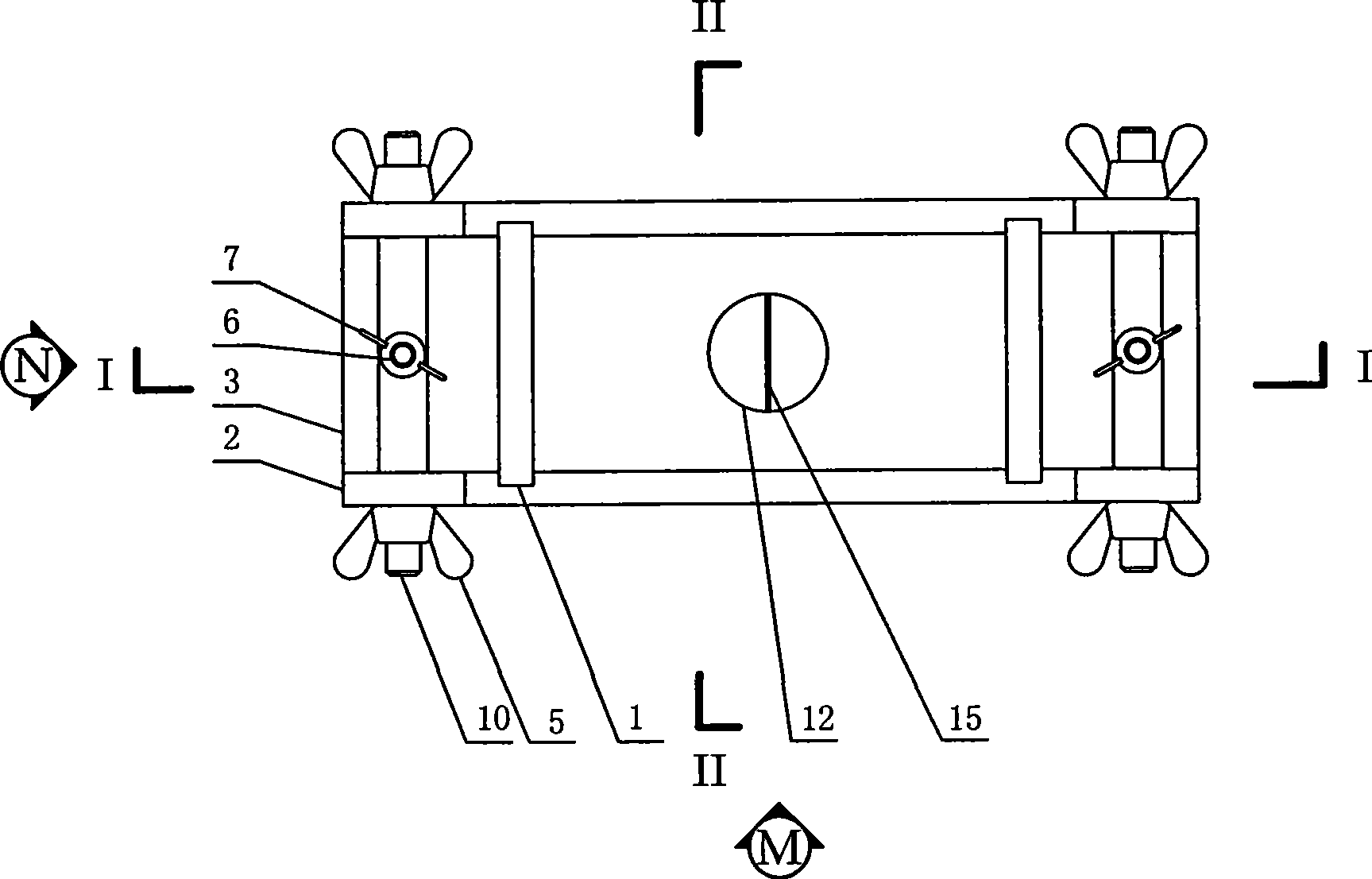

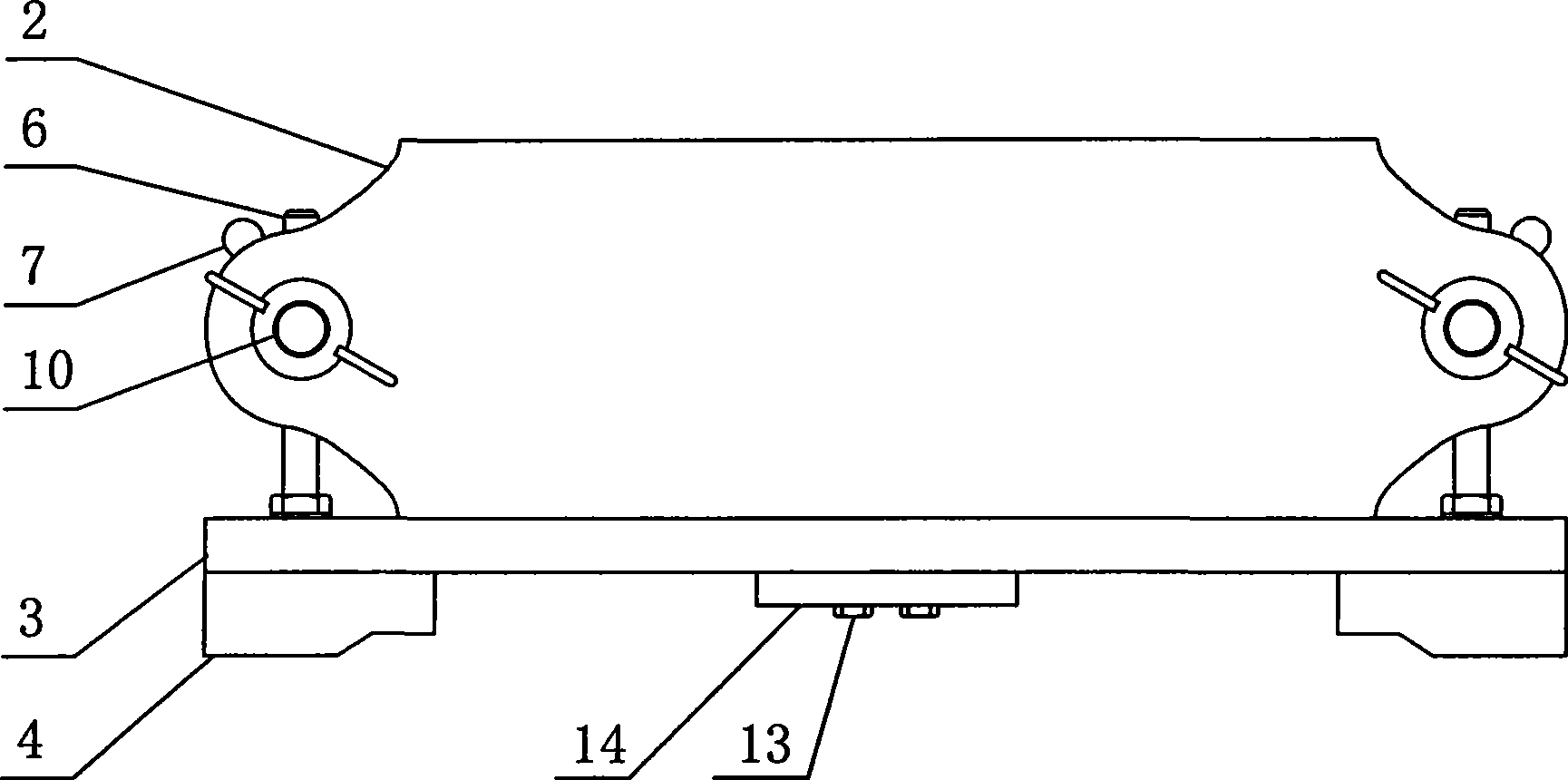

[0036] Figure 1-14 Among them, the bottom plate 3 is provided on the base 4, and the side plate 2, the end plate 1 and the vertical connecting rod 6 are vertically arranged on the bottom plate 3, and the two end plates 1 are vertically inserted between the two ends of the two side plates 2 respectively. , together form a frame with an upper opening, and two vertical connecting rods are respectively arranged between the two side plates 2 outside the two ends of the frame. The rods 10 are connected; the center of the bottom plate 3 is provided with a fixed slit device, and a plastic sheet 15 is provided on the fixed slit device.

[0037] Longitudinal grooves 16 and end holes 17 are symmetrically arranged on the side plate 2 , and both ends of the end plate 1 are placed in the longitudinal grooves 16 .

[0038] The end plate 1 is provided with several b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com