Oil film bearing for intelligent rolling mill

A technology of engine oil and bearings, which is applied in bearing assembly, bearing components, shafts and bearings, etc., can solve the problems of complex quality of rolled products, the thickness of oil film cannot be detected online, etc., achieve easy sealing and improve the quality of rolled products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

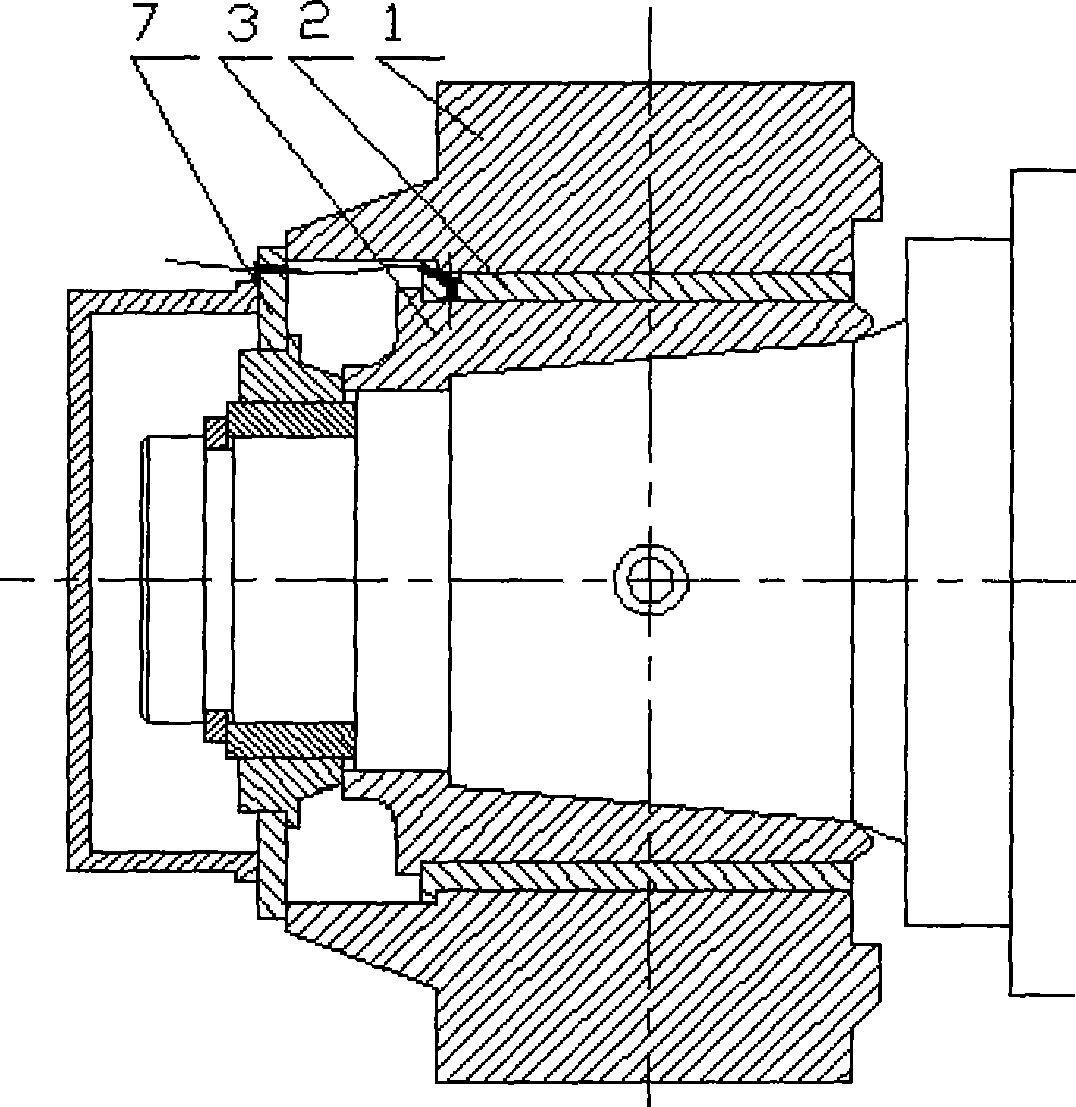

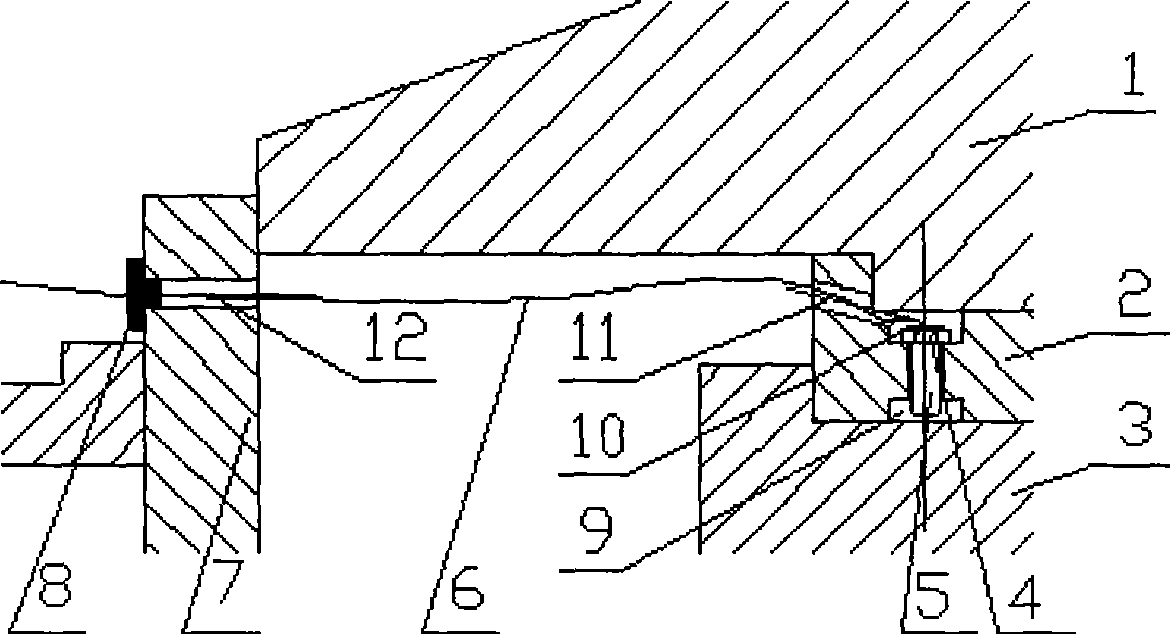

[0012] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing: See figure 1 with figure 2 , the intelligent rolling mill oil film bearing includes a rolling mill oil film bearing 2, which is characterized in that a small displacement sensor 5 is radially installed on the outer end of the rolling mill oil film bearing 2, and the signal lead-out line 6 of the displacement sensor 5 leads out to contain the rolling mill Outside the bearing housing 7 of the oil film bearing 2, it is connected to a secondary instrument or an acquisition card to a computer through an external preamplifier to form a monitoring and detection of the oil film of the bearing.

[0013] When the wall thickness of the rolling mill oil film bearing 2 is greater than 20 mm, the intelligent rolling mill oil film bearing can be realized, that is, a small displacement sensor 5 is accurately installed near the flange end. 1 is a bearing seat, and 3 is a ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com