Three-point contact ball bearing

A three-point contact, ball bearing technology, applied in the direction of ball bearings, bearing components, shafts and bearings to optimize stress conditions and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

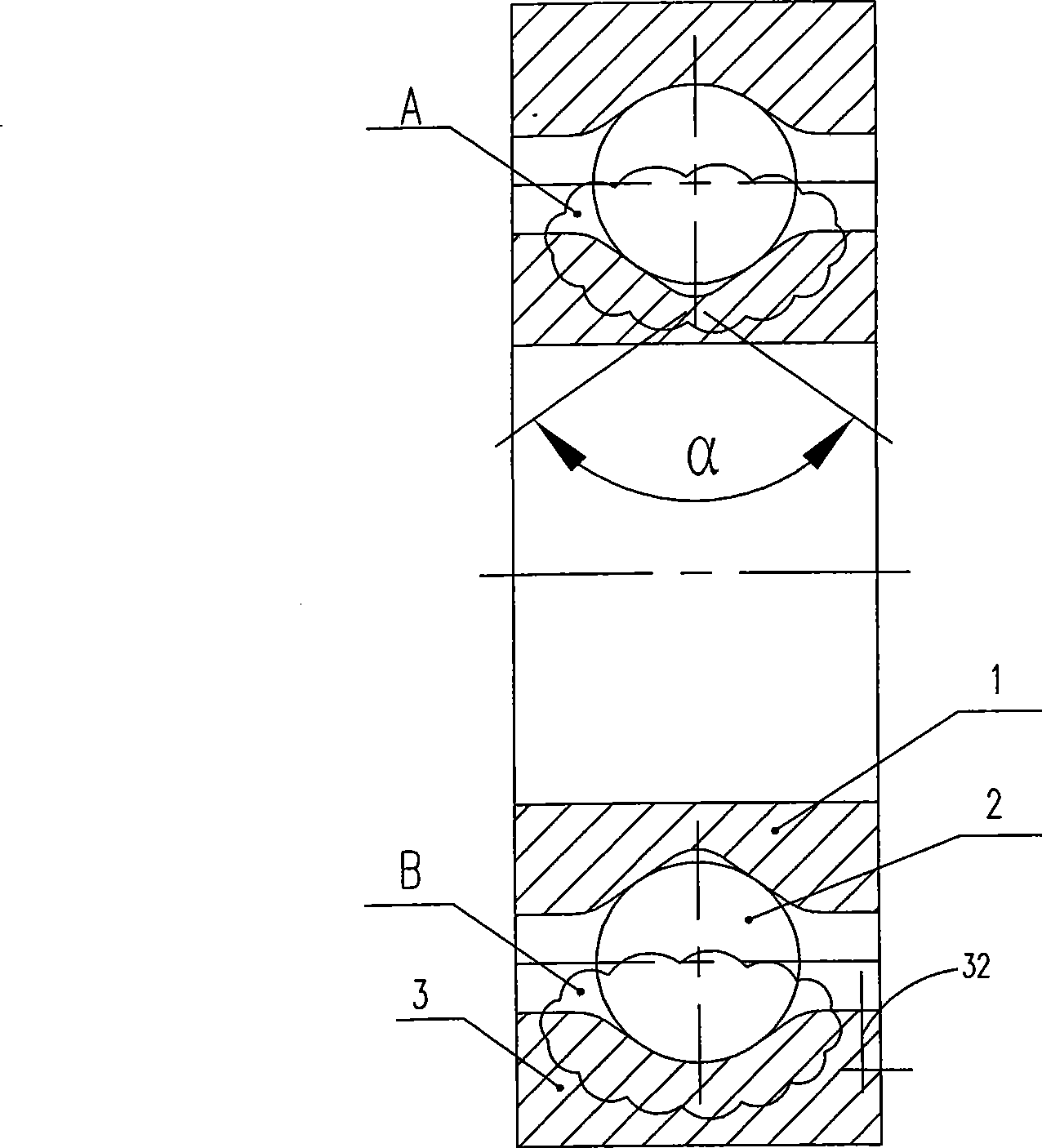

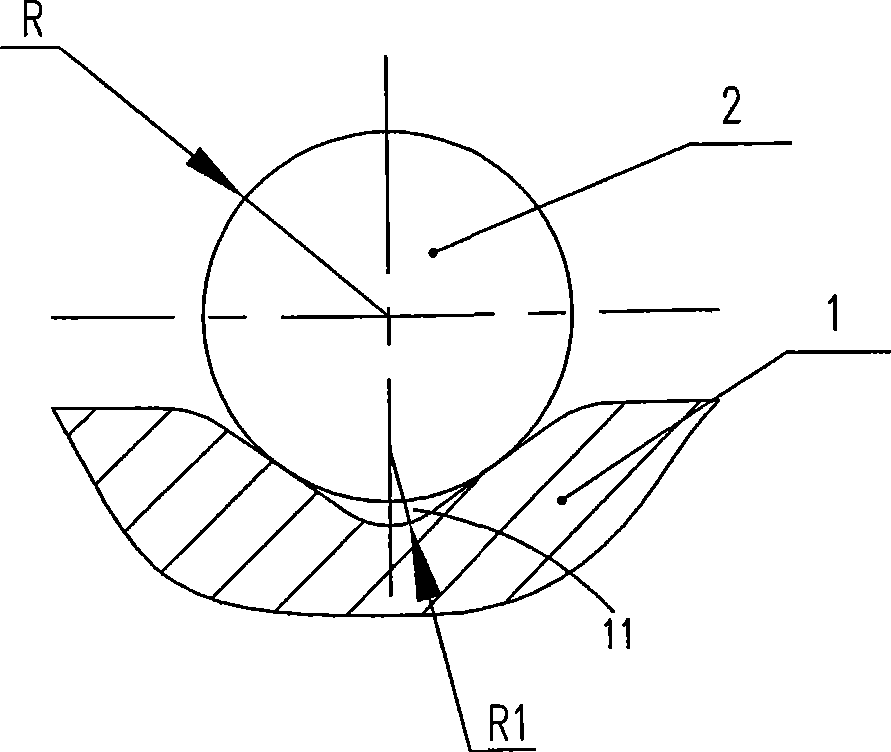

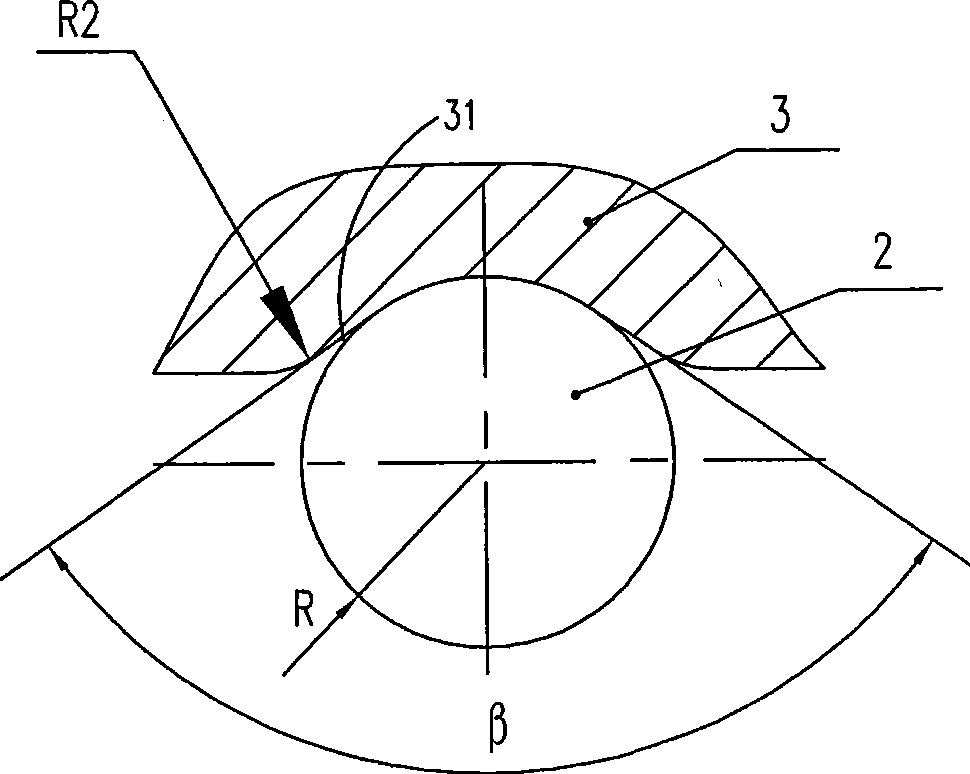

[0018] see Figure 1 ~ Figure 3 , the three-point contact ball bearing of the present invention includes a bearing inner ring 1, a rolling body 2 and a bearing outer ring 3; the rolling body 2 is arranged between the bearing inner ring 1 and the bearing outer ring 2; An annular track 11 with a U-shaped cross-section is provided, and an annular spherical track 31 is provided on the inner surface of the bearing outer ring 3; the annular spherical track 11 on the bearing inner ring 1 and the annular spherical track 31 on the bearing outer ring 3 and The angle between the contact point of the rolling body 2 and the center line of the rolling body 2 is between 150° and 270°.

[0019] The radius R1 of the connecting circle at the bottom of the circular track 11 on the bearing inner ring 1 is smaller than the radius R of the rolling body 2, the radius R2 of the annular spherical track 31 on the bearing outer ring 3 is greater than the radius R of the rolling body 2, and the rolling b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com