Construction machine

A technology for construction machinery and actuators, applied in the field of construction machinery with a stable monitoring system, can solve the problem of dust-proof, anti-pull, reduce the reliability of resistance sensing sheets, increase the difficulty of assembly and maintenance of construction machinery, and fail to detect the impact of supporting legs. problems such as force, so as to avoid the occurrence of vicious accidents, simple structure and avoid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

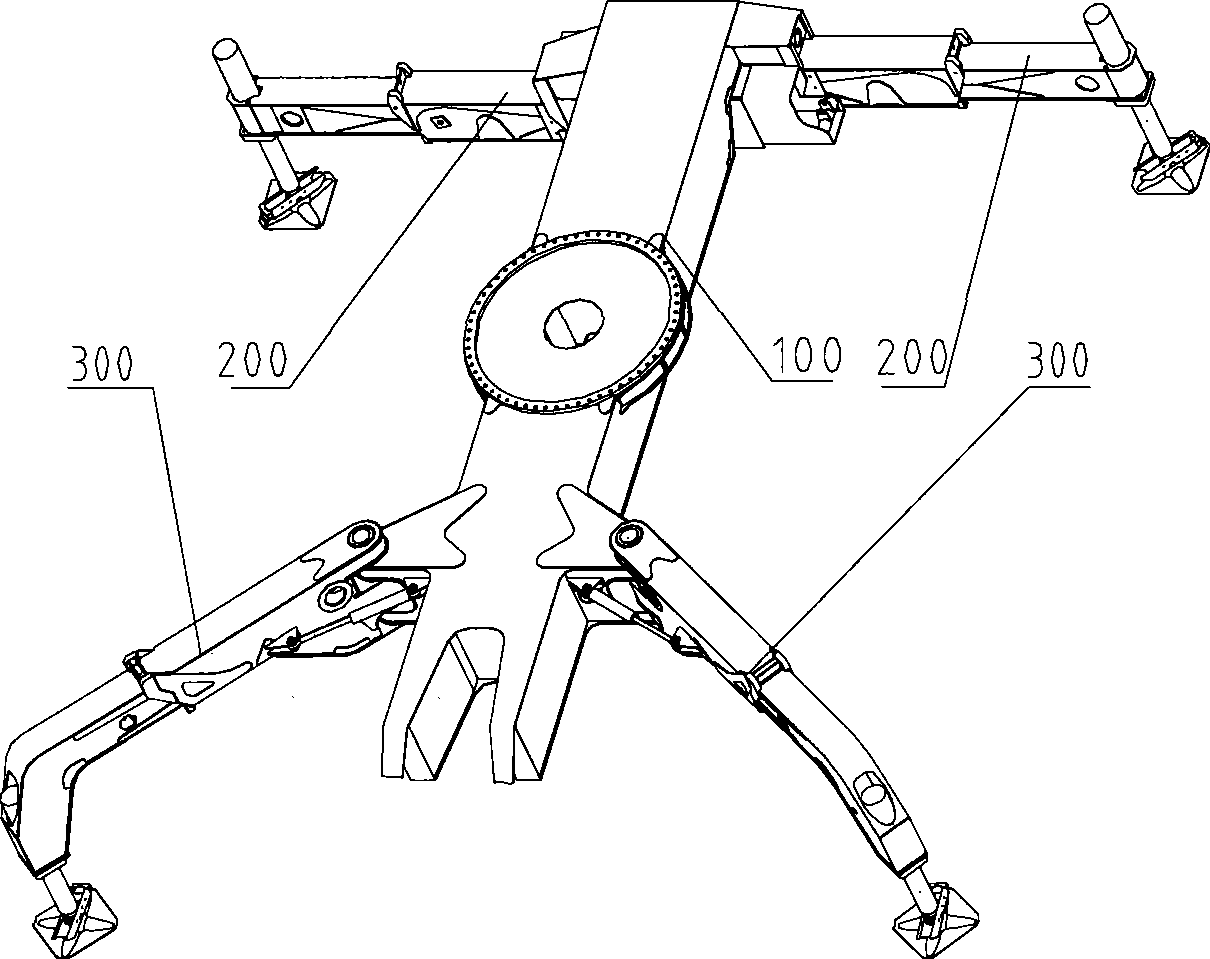

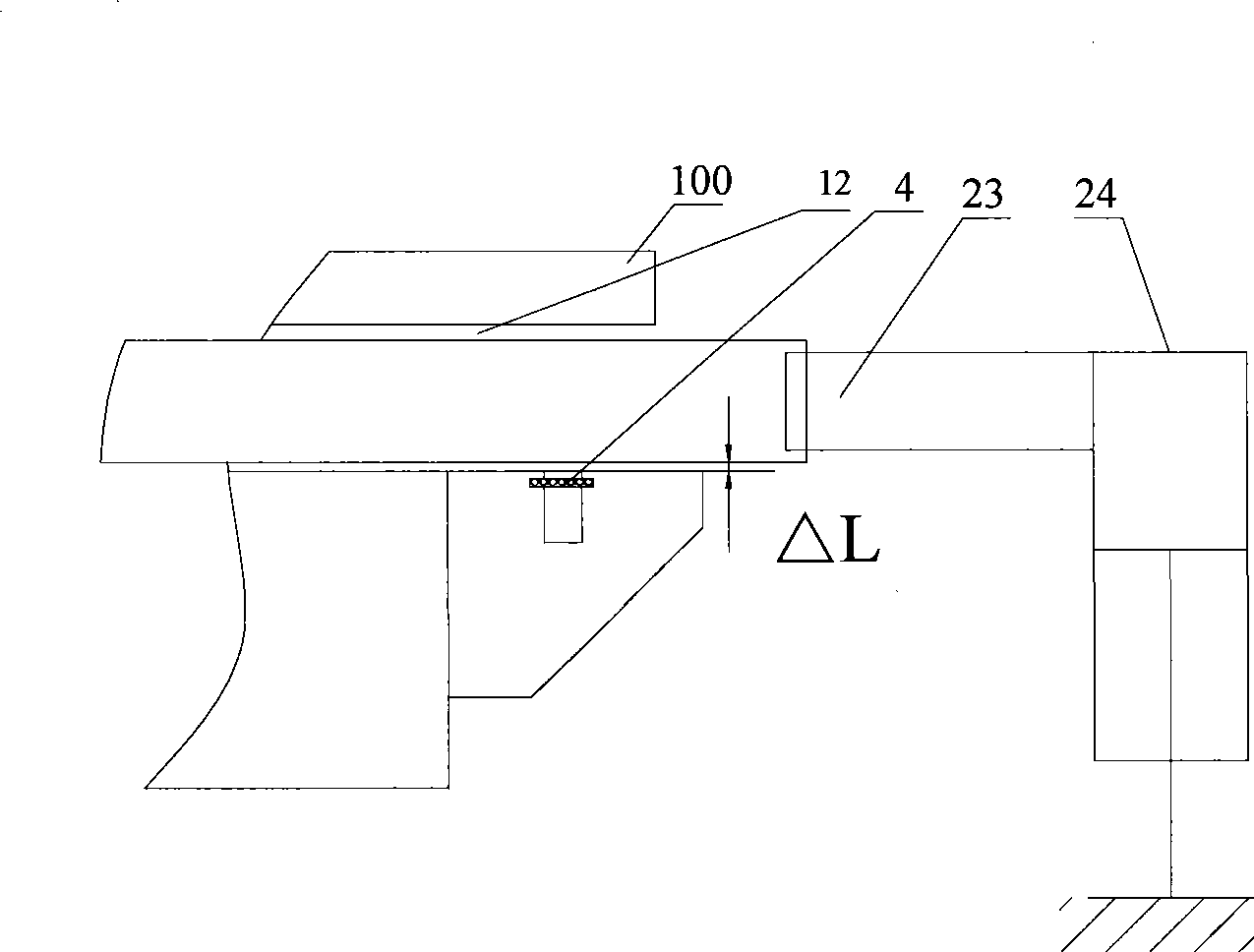

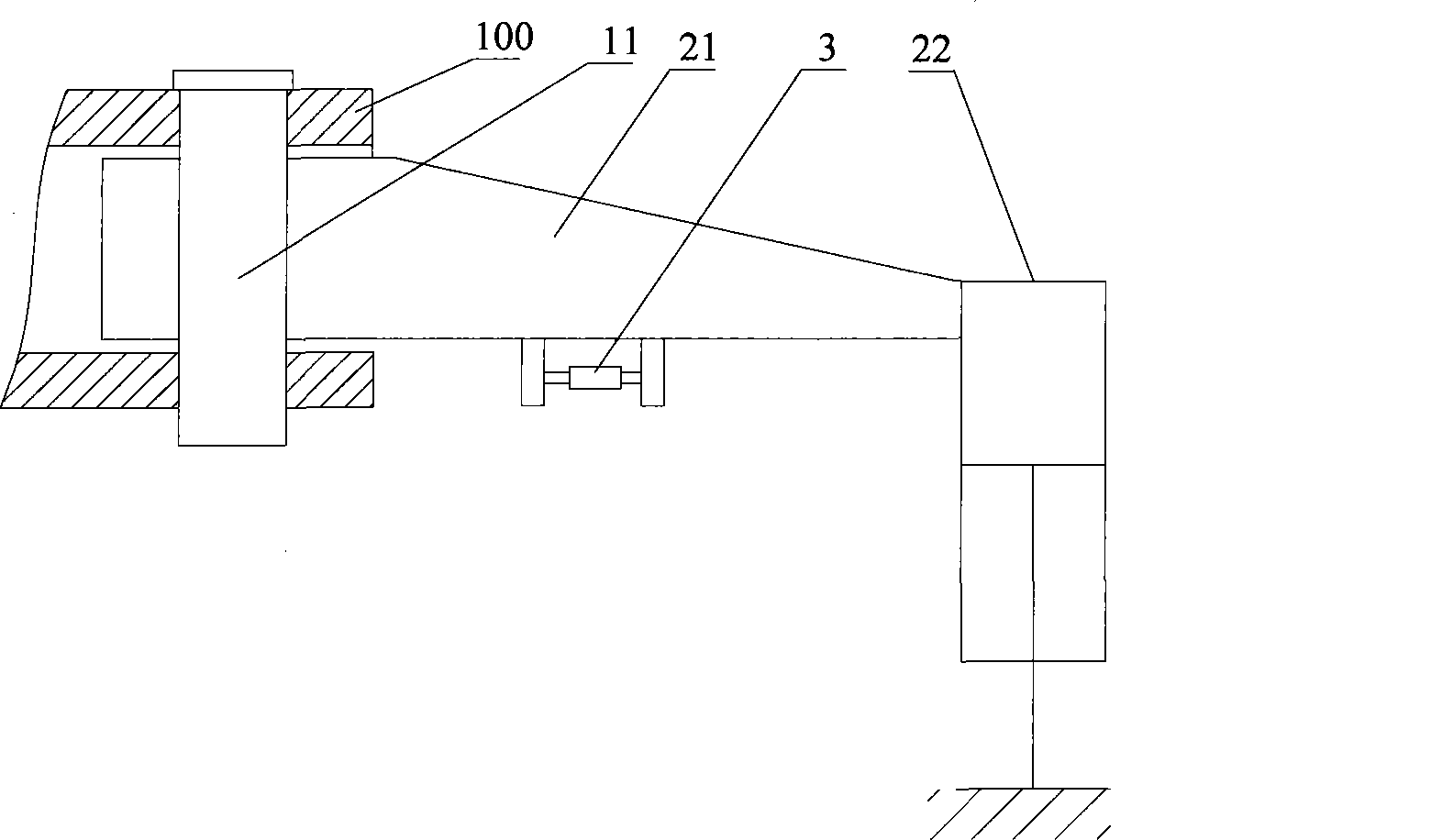

[0038] Embodiment 1 provides a kind of concrete pump truck, such as figure 1 As shown, the concrete pump truck includes a chassis 100, four support legs, including two front support legs 200 and two rear support legs 300, and also includes a construction arm and a hydraulic system that provides power for the construction arm rotation and amplitude change (Fig. not shown). Two front supporting legs 200 are floating supporting legs, such as figure 2 As shown, each front support leg 200 includes a telescopic arm 23 and a support cylinder 24 respectively, and the telescopic arm 23 cooperates with the outrigger slideway 12 at the front section of the chassis 100, and can be extended and retracted in the outrigger slideway 12. , it can provide a larger lateral support span for the concrete pump truck. Two rear supporting legs 300 are rigid supporting legs, such as image 3 As shown, each rear support leg 300 includes a support cylinder 22 and a support leg cantilever 21, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com