Thermal printer

一种印刷机、热敏的技术,应用在印刷、打印装置、着墨装置等方向,能够解决印刷不可能等问题,达到提高可靠性、防止凹口脱落的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

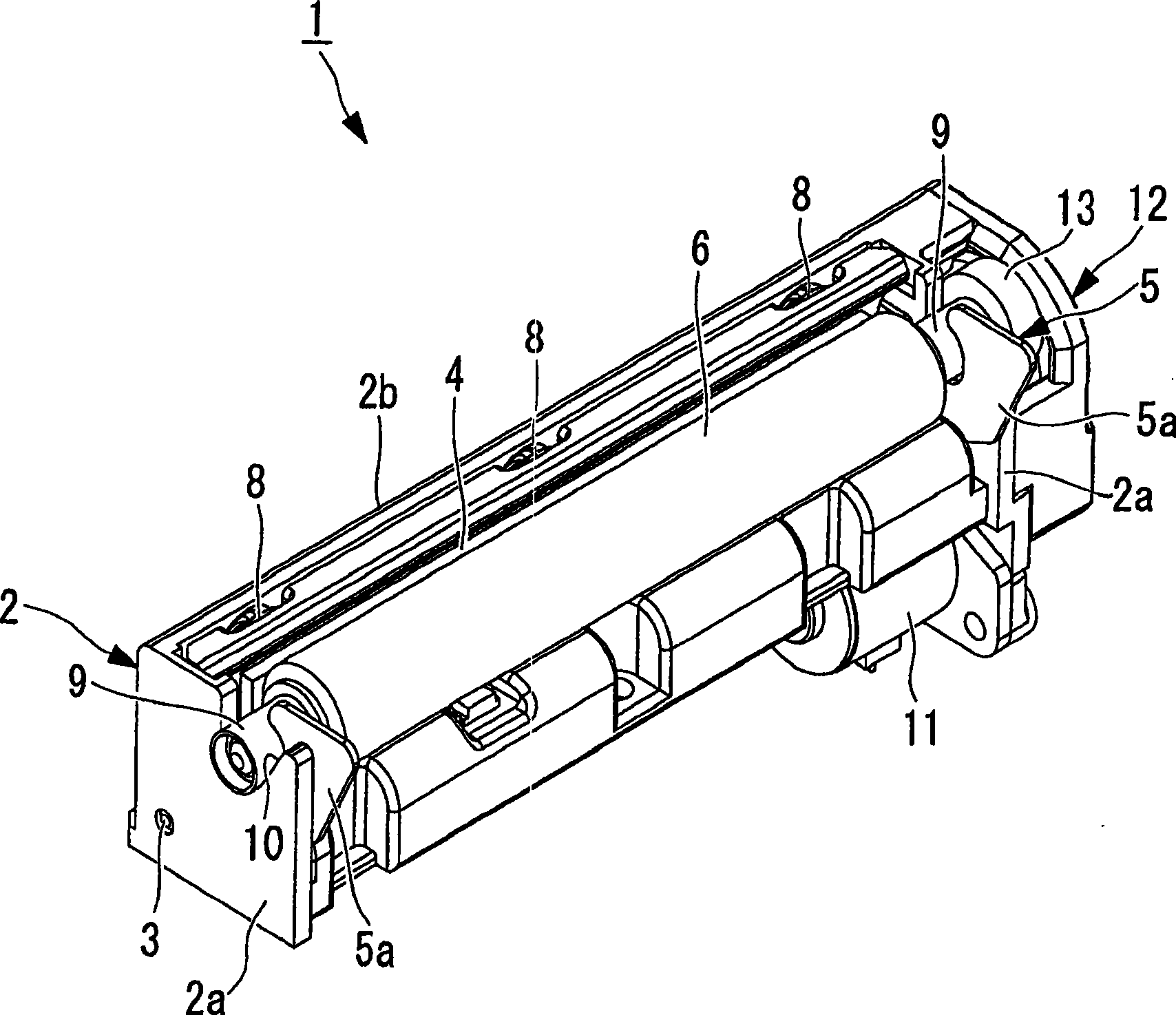

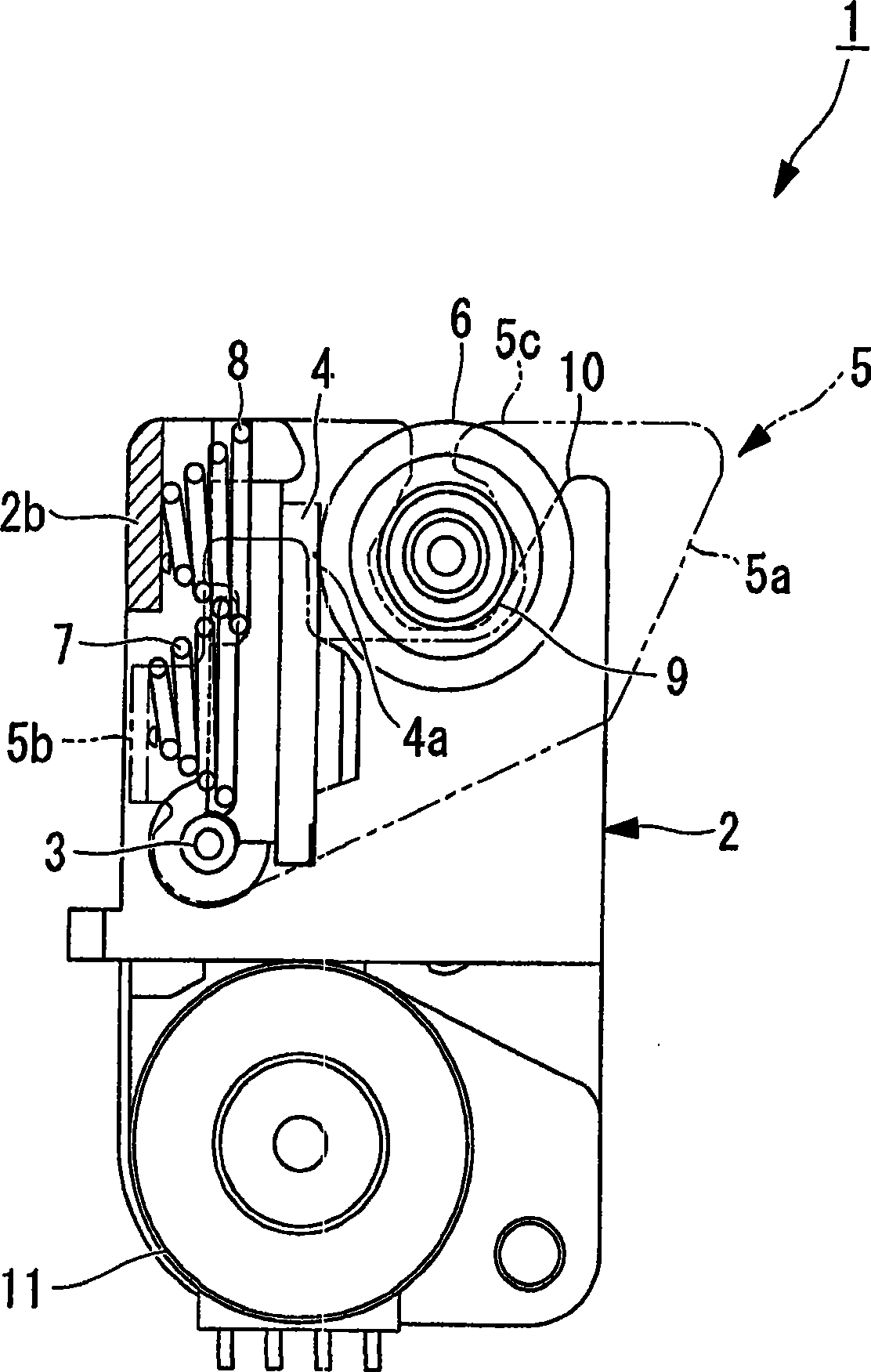

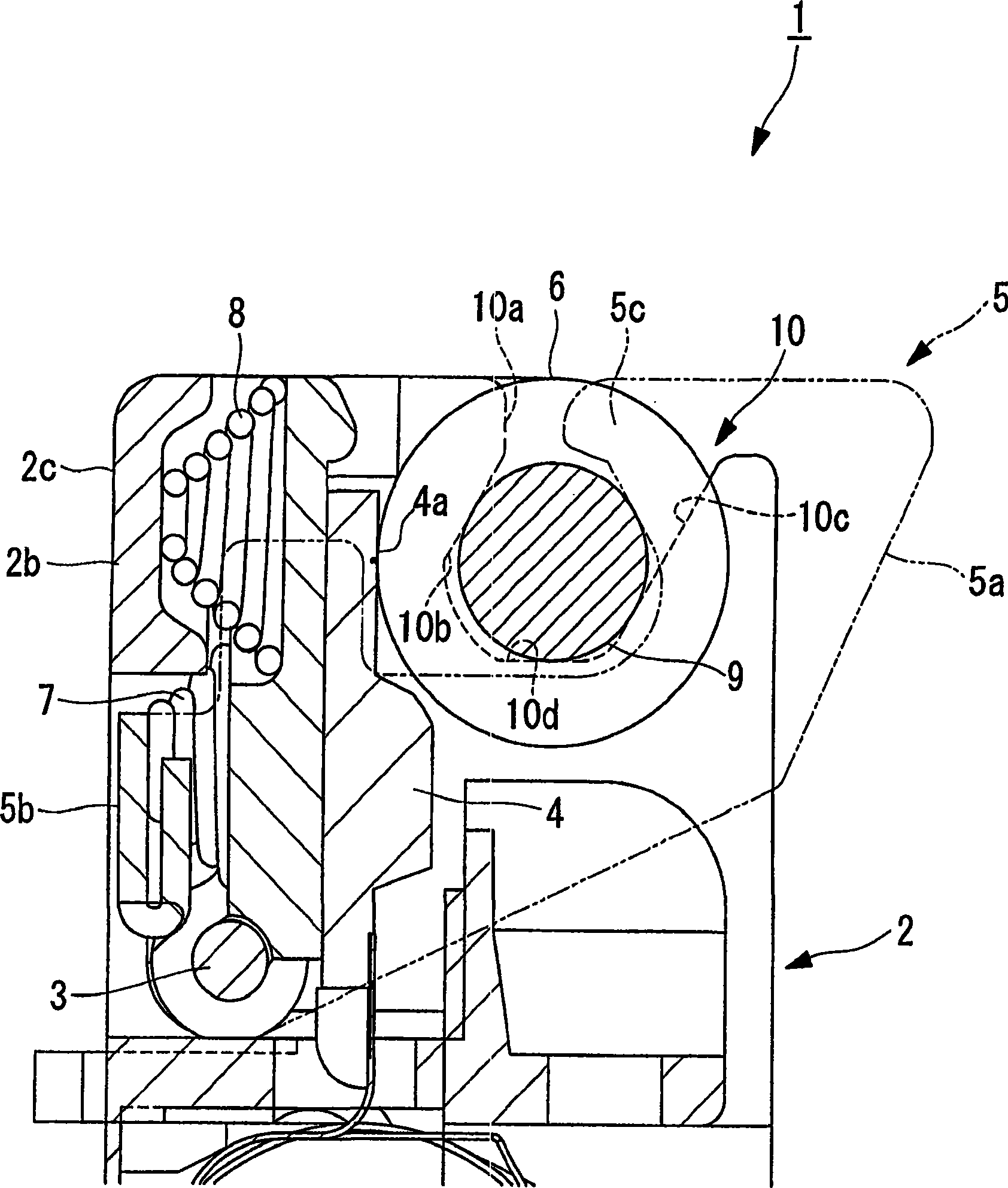

[0019] In the following, refer to figure 1 4A-4B describe a thermal printer according to a first embodiment of the present invention.

[0020] figure 1 is a perspective view showing the thermal printer according to this embodiment. figure 2 to show the installed figure 1 A longitudinal cross-sectional view of the state of the embossing roller of a medium thermal printing machine. image 3 for figure 2 A zoomed-in view of the main part of . 4A to 4B are views showing a state where the embossing roller and the bearing are moved to the side opposite to the shaft, wherein FIG. 4A is the same as image 3 Similar views, and Figure 4B is a further enlarged view of the main part in Figure 4A.

[0021] Such as figure 1 As shown, the thermal printer 1 of this embodiment comprises: a main body frame 2; a thermal head 4 and a locking arm 5 that is swingably installed on the concentric shaft (support shaft) 3 of the main body frame 2; supported by the locking arm 5 An embossing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com