Fabric-like recombined decorated veneer and manufacture method thereof

A technology for reorganizing decoration and manufacturing methods, applied in the field of wood processing, can solve problems such as complex processes, and achieve the effect of bright colors, clear lines, and bright colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

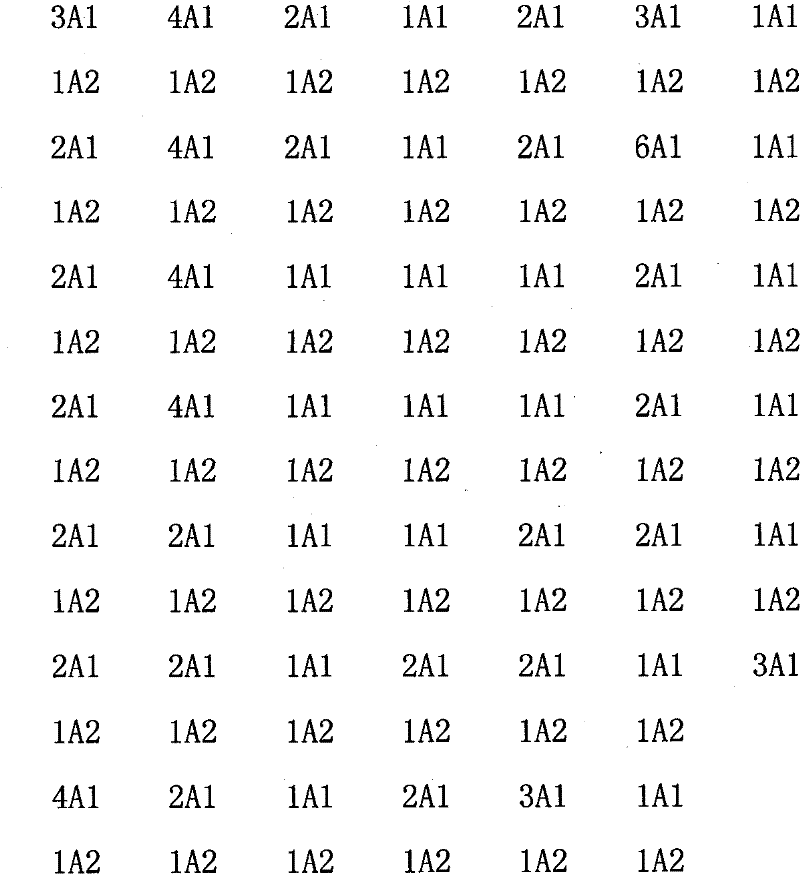

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention is described in detail below with the production method of cypress.

[0026] 1. Put the 0.75mm thick basswood veneer into the bleaching tank. The bleaching agent is 35% (anti-reduction grade) hydrogen peroxide, the concentration of the bleaching agent is 3%, the pH value=11 of the bleaching solution is adjusted with 30% sodium hydroxide solution, the bleaching auxiliary agent is sodium silicate, and the bleaching time is 45 minutes.

[0027] 2. Use strong acid dyes red, yellow and blue, the temperature of the dye solution is 95°C, the concentration of the dye solution is 0.8%, and the dyeing time is 6 hours.

[0028] 3. Use a mesh belt dryer to dry, and the moisture content of the veneer is controlled at 6%.

[0029] 4. Excavate and repair the dried veneer with an electric grinder. The electric grinder has a spherical surface of the sand head. Through the contact between the spherical surface of the sand head and the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com