Quick discharging method of material to be removed in electric spark machining

A technology of electric spark and machining area, which is applied in the field of accelerated discharge of removed materials, can solve the problems of decreased machining quality and machining efficiency, abnormal discharge, short circuit, etc., and achieves the effect of improving machining quality and machining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

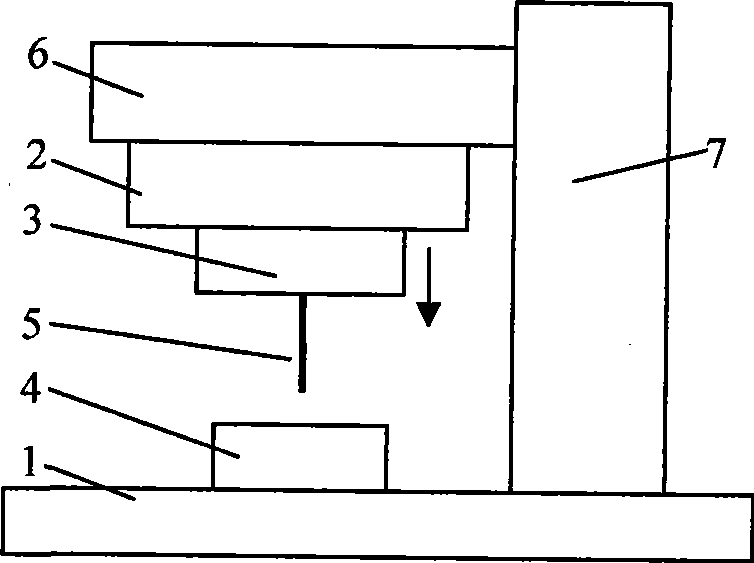

[0009] The specific implementation manner of the present invention is described in detail in conjunction with accompanying drawing and technical scheme, below with figure 1 , figure 2 The two electric discharge machining devices shown are taken as examples to illustrate the specific implementation of the present invention.

[0010] figure 1 It is a schematic diagram of an EDM device for applying ultrasonic vibration to a workpiece 4 and simultaneously driving the workpiece 4 to realize periodic relative motion between the tool electrode 5 and the workpiece 4. It is mainly composed of a base 1, an XY drive unit 2, an ultrasonic generator 3, and a workpiece 4 , a tool electrode 5, a lifting arm 6 and a column 7. Among them: the XY driving unit 2 can realize any two-dimensional movement on the plane; the lifting arm 6 can rise and fall along the column 7; the workpiece 4 is fixed on the upper surface of the ultrasonic generator 3; the bottom surface of the ultrasonic generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com