Fermentation-method theabrownin preparation method

A technology of theabrownin and fermentation method, which is applied in the field of tea processing, can solve problems such as no public reports, and achieve the effects of high efficiency, fast speed, easy control of production conditions and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The present invention utilizes the method for microbial fermentation to obtain theabrownin rapidly, and the specific method is as follows:

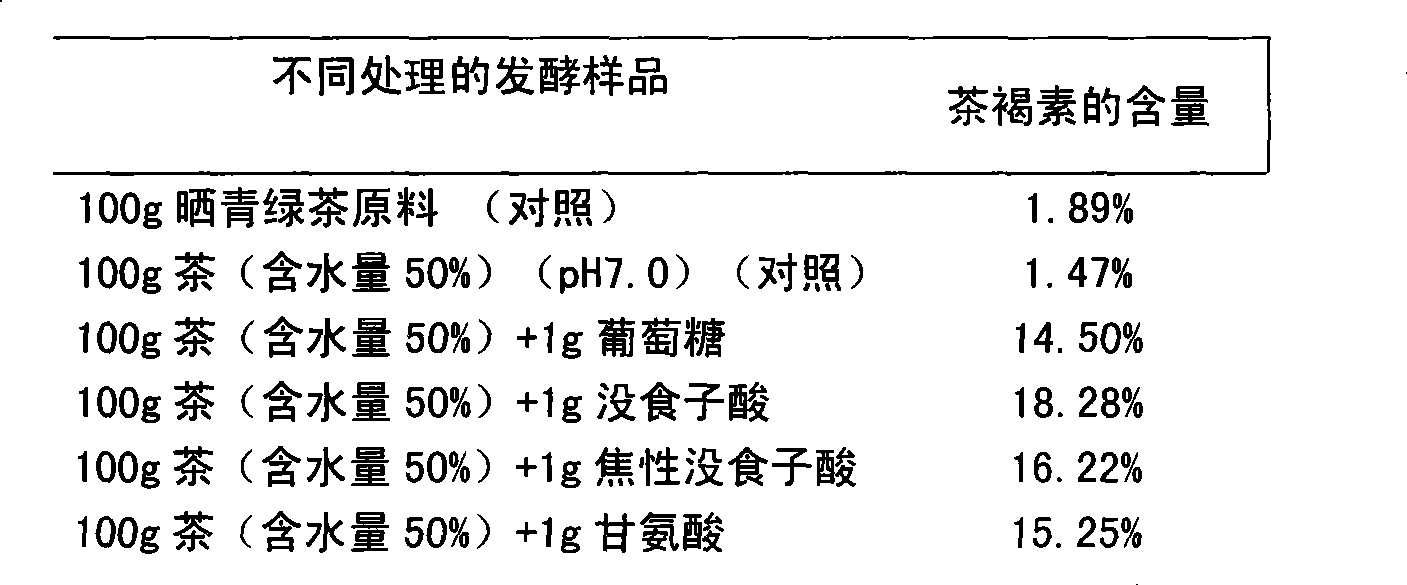

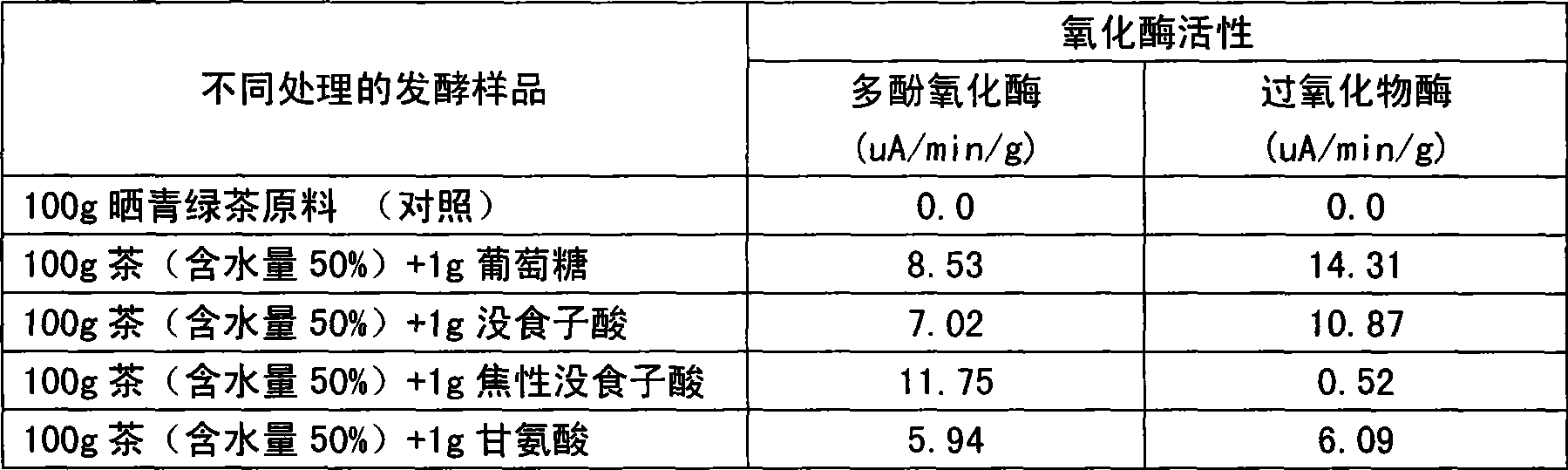

[0013] A. Crush the tea to 60 mesh, sterilize it by ultraviolet light for 30 minutes, add deionized water according to the standard of 50% final water content of the tea leaves, at the same time, inoculate the commercially available food yeast or aspergillus in the water in proportion and add 1% Gallic acid or pyrogallic acid or glycine or glucose, food additives / tea raw material mass g / g, let stand for 60 minutes to allow the tea to fully and evenly absorb water, after the tea has fully absorbed water, seal it with a food preservative film. Then place it under the conditions of ventilation, 35 DEG C, and 60% humidity, and cultivate it in the dark for 20 days to obtain fermented tea leaves with high content of theabrownin.

[0014] B. Dry the fermented tea leaves at 60°C until the water content is 10%, soak for 30 minutes according...

Embodiment 2

[0022] Basically with embodiment 1. The difference is: in step A, the tea is pulverized to 70 meshes, the cultivation temperature is 45° C., and the humidity is 70%.

Embodiment 3

[0024] Basically with embodiment 1. The differences are: in step A, the tea is pulverized to 80 meshes, the cultivation temperature is 55° C., and the humidity is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com