Yarn leading roller apparatus for ring spinner

A ring spinning machine and yarn drawing technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problem of non-parallelism of front roller pairs, large difference in pressure of each spindle, and increased pressure. Unstable pressure and other problems, to overcome changes in mechanical properties, improve uniformity, and reduce yarn defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

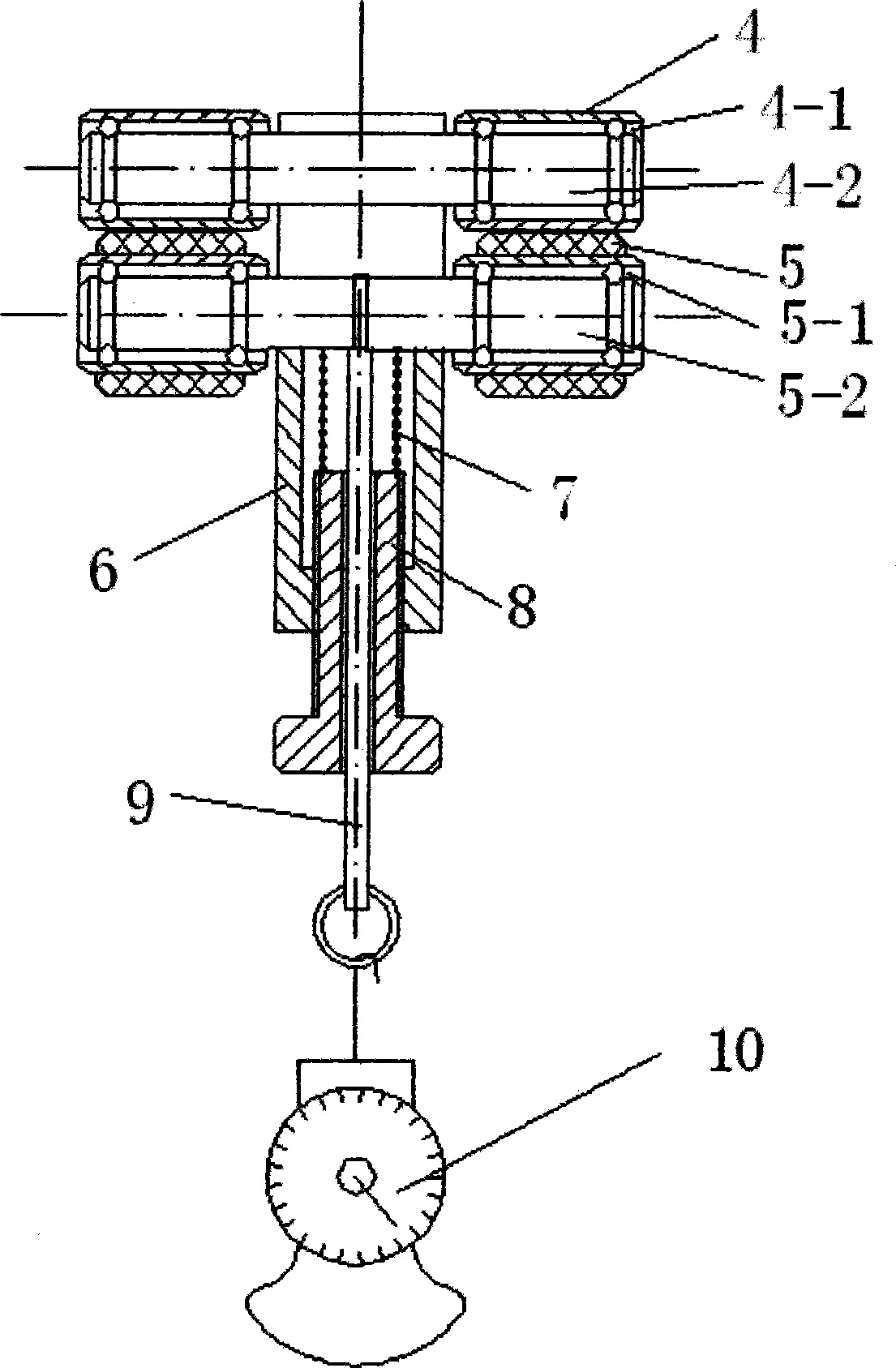

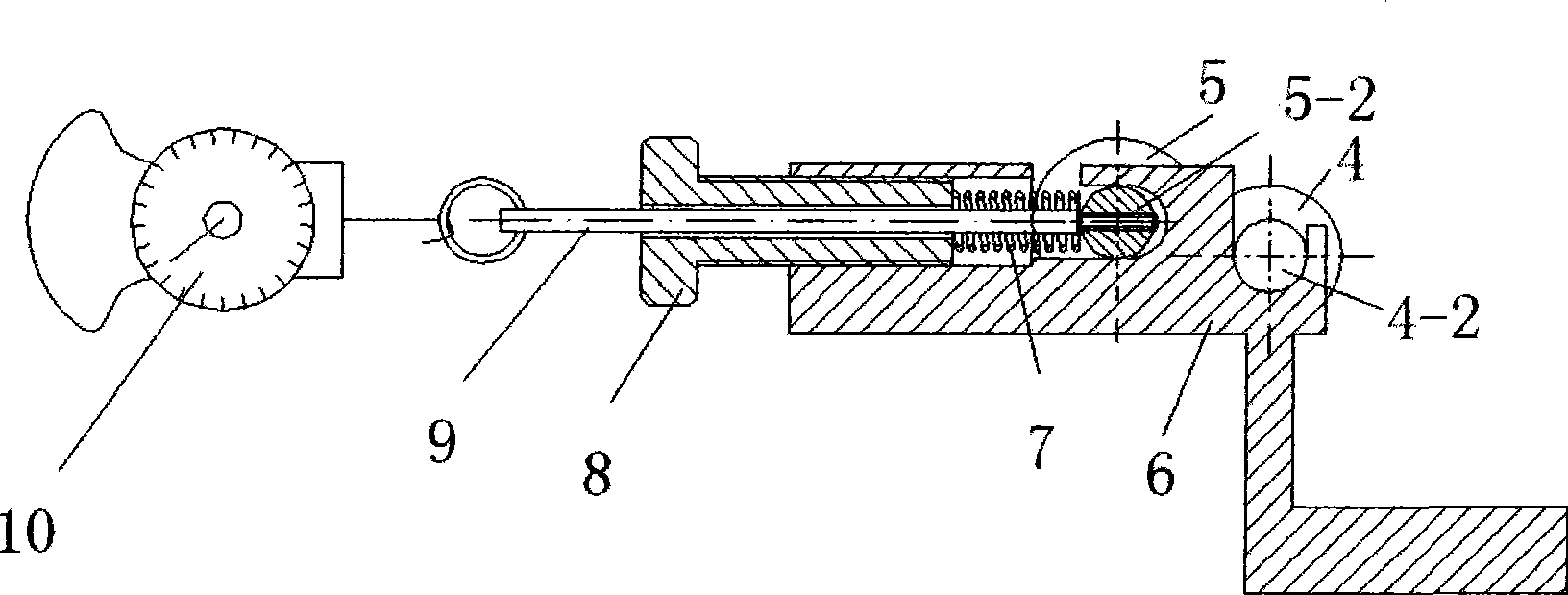

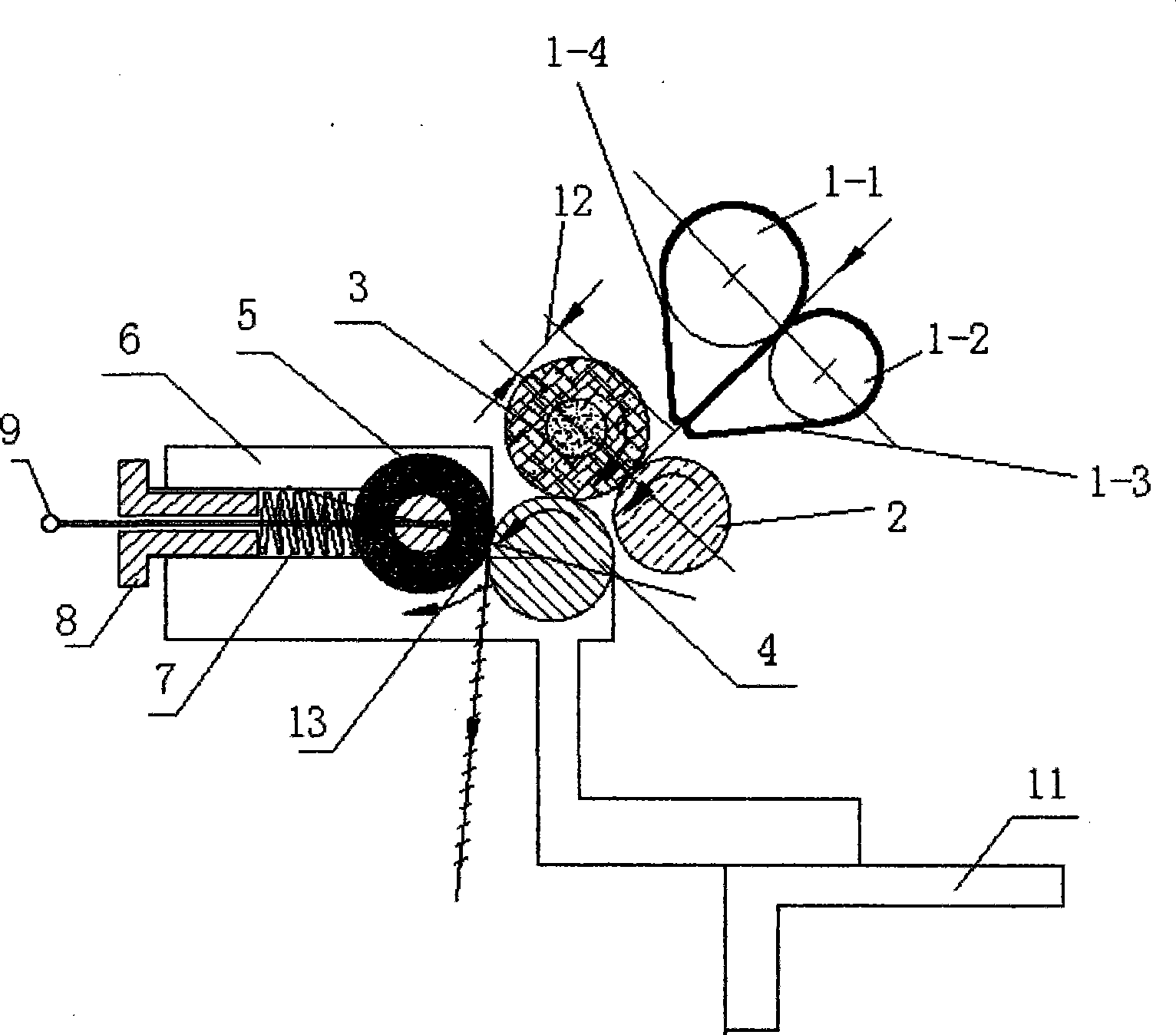

[0011] according to figure 1 As shown, yarn drawing roller 4 is respectively fixed on the two ends of roller mandrel 4-2 by bearing 4-1, and the center of roller mandrel 4-2 is fixed on the device seat 6. Yarn leading top roller 5 is connected on the two ends of yarn leading top roller mandrel 5-2 respectively by bearing 5-1, and the middle of yarn leading top roller mandrel 5-2 is installed in the chute of device seat 6 (see figure 2 ). The pressure spring 7 and the pressure screw 8 are installed in the hole of the device seat 6, and the two ends of the pressure spring 7 are respectively pressed against the middle of the yarn leading roller mandrel 5-2 and the pressure screw 8, and the pressure screw is rotated 8. The pressure between the yarn delivery roller 4 and the yarn delivery top roller 5 can be adjusted. Offer a hole in the middle of the pressure screw 8, a load cell 9 is adorned in the hole, and one end of the load cell 9 connects the yarn-leading top roller mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com