Wood heat treatment device

A technology of wood heat treatment and heat treatment equipment, applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve problems such as not suitable, decay and insect damage, anisotropy, etc., and achieve simple structure and good use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

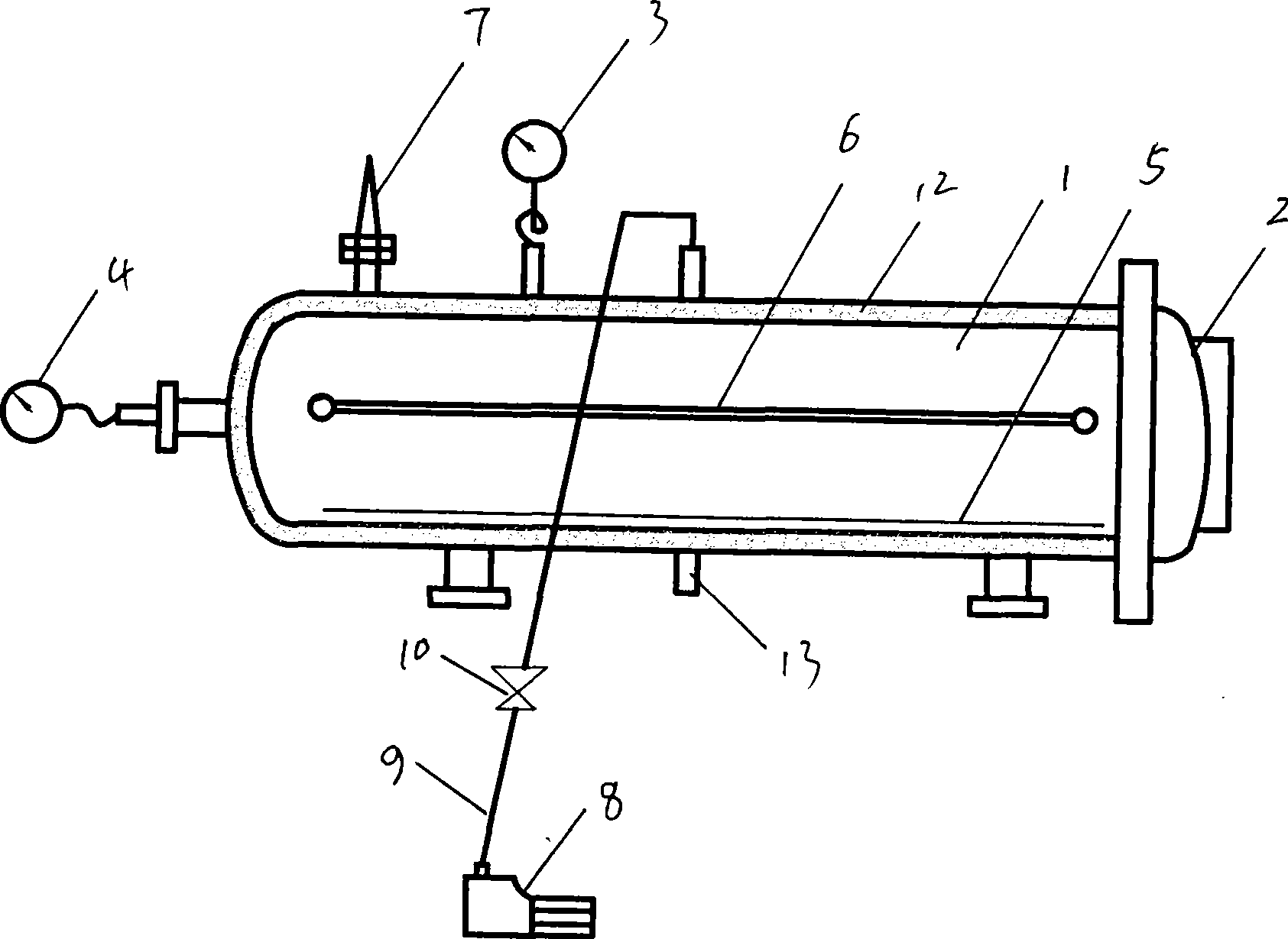

[0008] control figure 1 As can be seen, the present invention comprises a metal sealed pressure tank 1, and one end of the sealed pressure tank 1 is provided with a tank door 2, and a pressure gauge 3, a thermometer 4 and a safety valve 7 are also arranged on the sealed pressure tank in addition, so as to facilitate observation of the inside of the tank. The pressure and temperature of the airtight pressure tank are provided with transport rails 5 and steam spray pipes 6 to facilitate the entry and exit of wood and the injection of steam. Evenly distribute small holes (not marked in the figure) on the described spraying steam pipe 6, and the two ends of the sprayed steaming pipe are connected with the steam source outside the sealed pressure tank by a conduit (not marked in the figure), in the sealed pressure tank 1 There is also a vacuuming device outside, and the vacuuming device includes a vacuum pump 8, and the vacuum pump 8 is connected to the sealed pressure tank 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com