Method for installing an optical fiber safety prewarning sensor

An installation method and safety early warning technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problem of no effective method for safety protection, the installation method of optical fiber safety early warning sensors, and the reduced effectiveness of protection, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

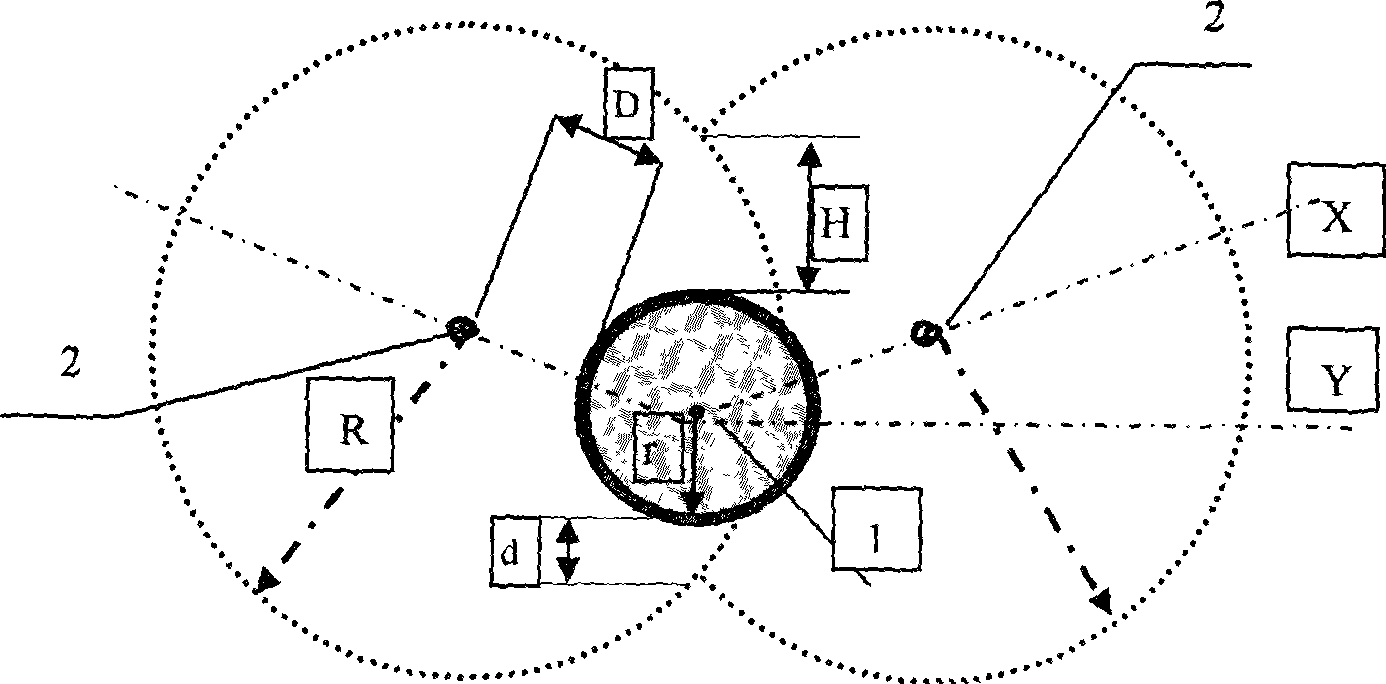

[0033] Embodiment 1. Use this example to illustrate the specific implementation of the present invention and further illustrate the present invention. This example is an optical fiber sensor installation method for installing an optical fiber safety early warning system on a Φ1500mm pipeline, where the pipeline radius is r=750mm, the sensitivity R of the sensing optical cable 2 is 1500mm, and the distance between the optical cable and the pipeline is D=300mm, according to the conditions of the installation method R>2r +D Judgment, the condition is not satisfied, it is necessary to install a sensing optical cable, the number of optical cables must be >|π(2r+D) / 2R| to be 2, and its composition is as follows figure 2 shown. Install two sensing optical cables 2 along the pipe trench of the pipeline, and the laying position is: install the two sensing optical cables 2 on both sides of the pipeline 1 obliquely above the position close to the same horizontal plane, and the vertical ...

Embodiment 2

[0034] Embodiment 2. This example is to install the optical fiber sensor of the optical fiber safety early warning system to four 100,000 cubic crude oil storage tanks arranged in a square. Since the oil tank area covers an area of 400×400m, a set of optical fiber safety early warning system is adopted, and a sensing optical cable 2 is laid three times around the oil tank area in a square spiral shape and buried at a depth of 1 meter underground with a pitch of 6 meters. The sensing optical cable 2 installed by this method is used by the optical fiber safety early warning system, which can warn an 18-meter-wide square ring around the oil tank area, and the signal sensitivity is high, effective, reliable, and very ideal.

[0035] It can be seen that the optical fiber sensor installed by this method has high signal sensitivity, is effective and reliable, and provides an ideal optical fiber sensor installation method for the optical fiber safety early warning system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com