Polycrystalline silicon manufacturing apparatus and manufacturing method

A technology for manufacturing equipment and manufacturing methods, applied in the field of polysilicon manufacturing equipment, capable of solving problems such as supplying raw material gas, falling down, and swinging silicon core rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the polysilicon manufacturing apparatus and manufacturing method of the present invention will be described with reference to the drawings.

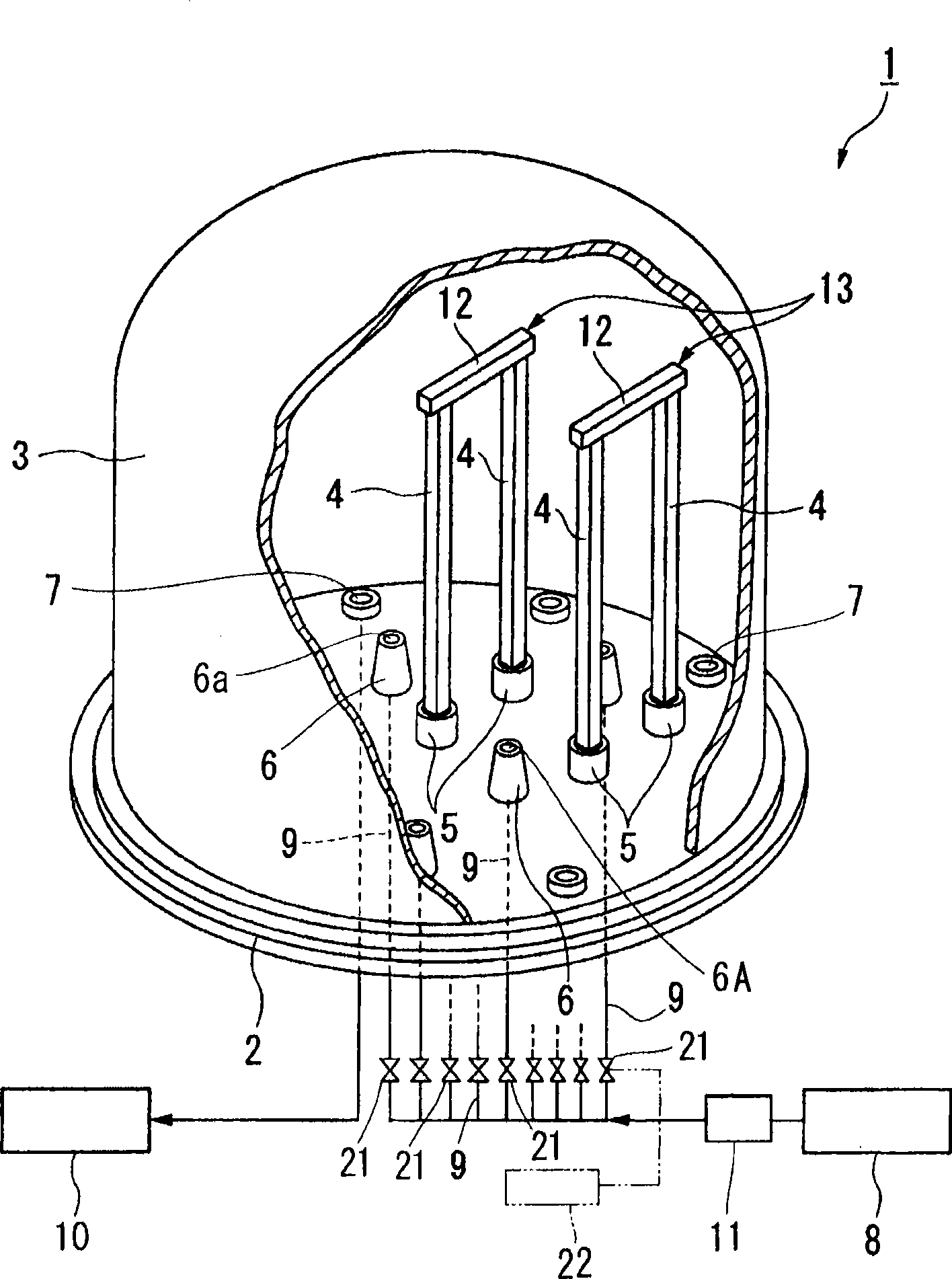

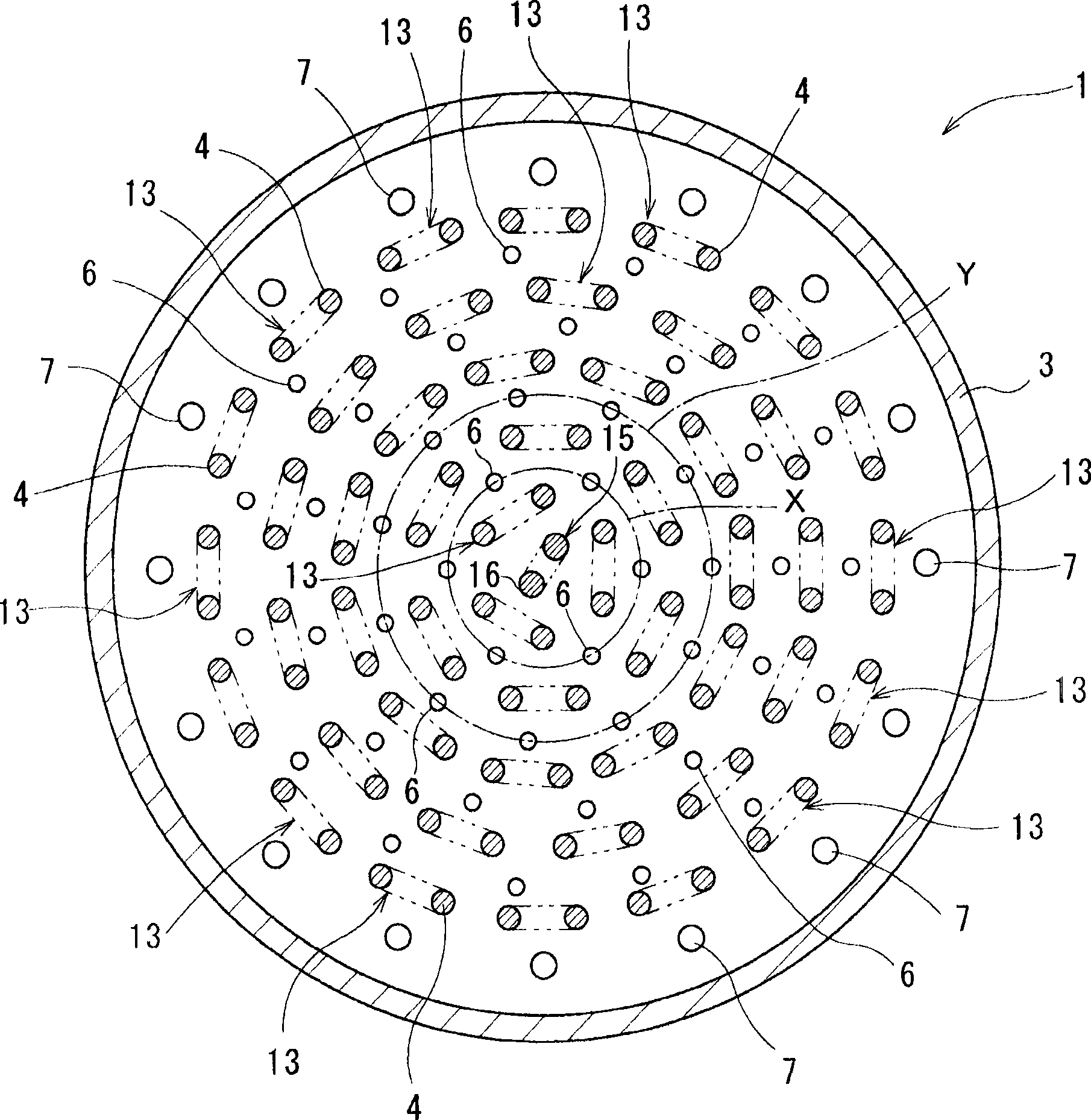

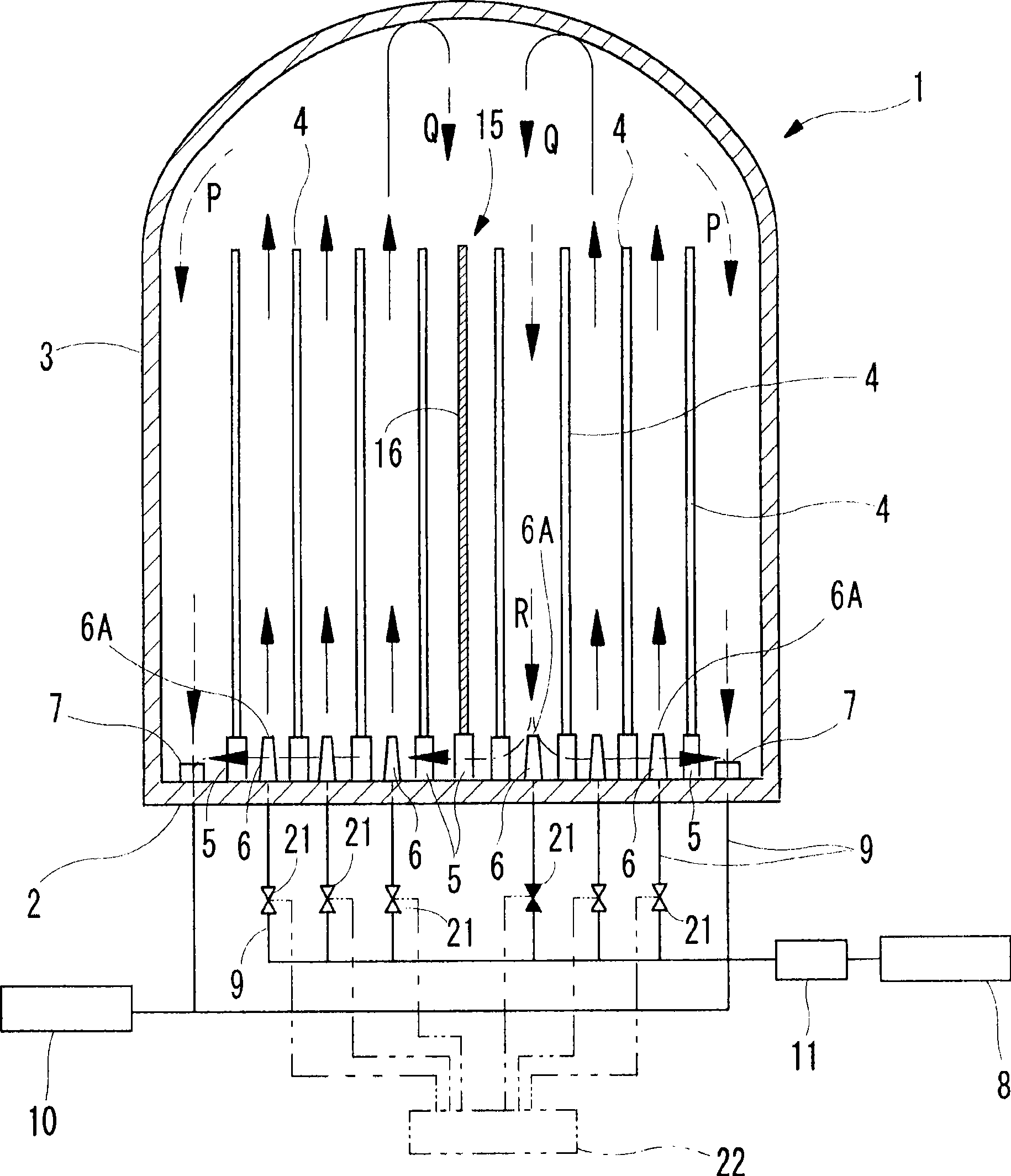

[0045] figure 1 It is an overall view of a polycrystalline silicon manufacturing apparatus using the present invention. The reaction furnace 1 of the polycrystalline silicon manufacturing apparatus includes: a base 2 constituting the bottom of the furnace; and a bell-shaped cover 3 detachably attached to the base 2 .

[0046] like figure 1 As shown, a plurality of the following components are respectively arranged on the base 2: a plurality of pairs of electrodes 5 are installed with a silicon core rod 4 which becomes a seed rod of polysilicon generated; an ejection nozzle 6 is used to inject chlorosilane gas and The raw material gas of hydrogen is sprayed into the furnace; the gas outlet 7 is used to discharge the reacted gas to the outside of the furnace.

[0047] In addition, the ejection nozzles 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com