Hydraulic controlled vehicle power transmission mechanism

A technology of power transmission mechanism and transmission mechanism, applied in the direction of control devices, vehicle parts, transportation and packaging, etc., can solve the problems of troublesome design of cabin parts, difficulty of large layout, complex control mechanism and corresponding pipeline layout, etc., to achieve Save space, improve reliability, and improve transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

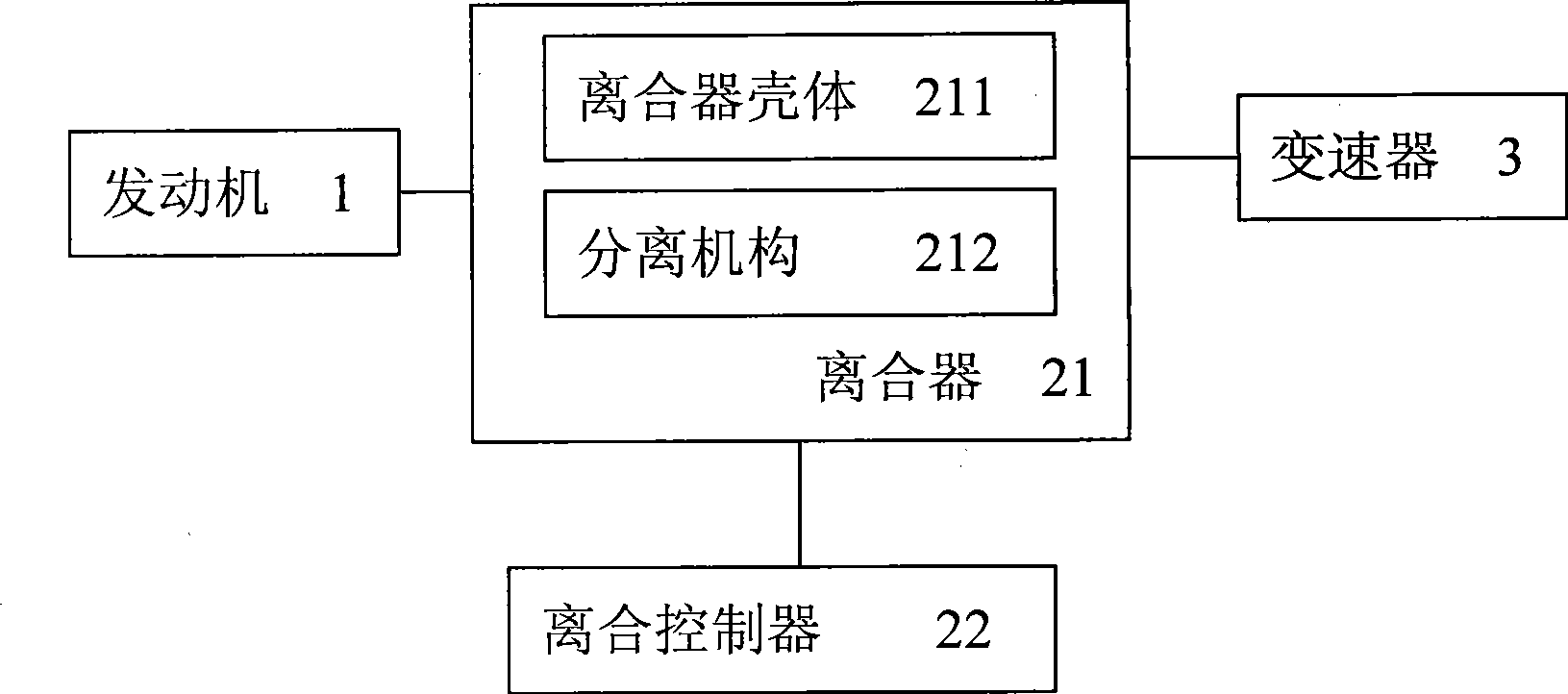

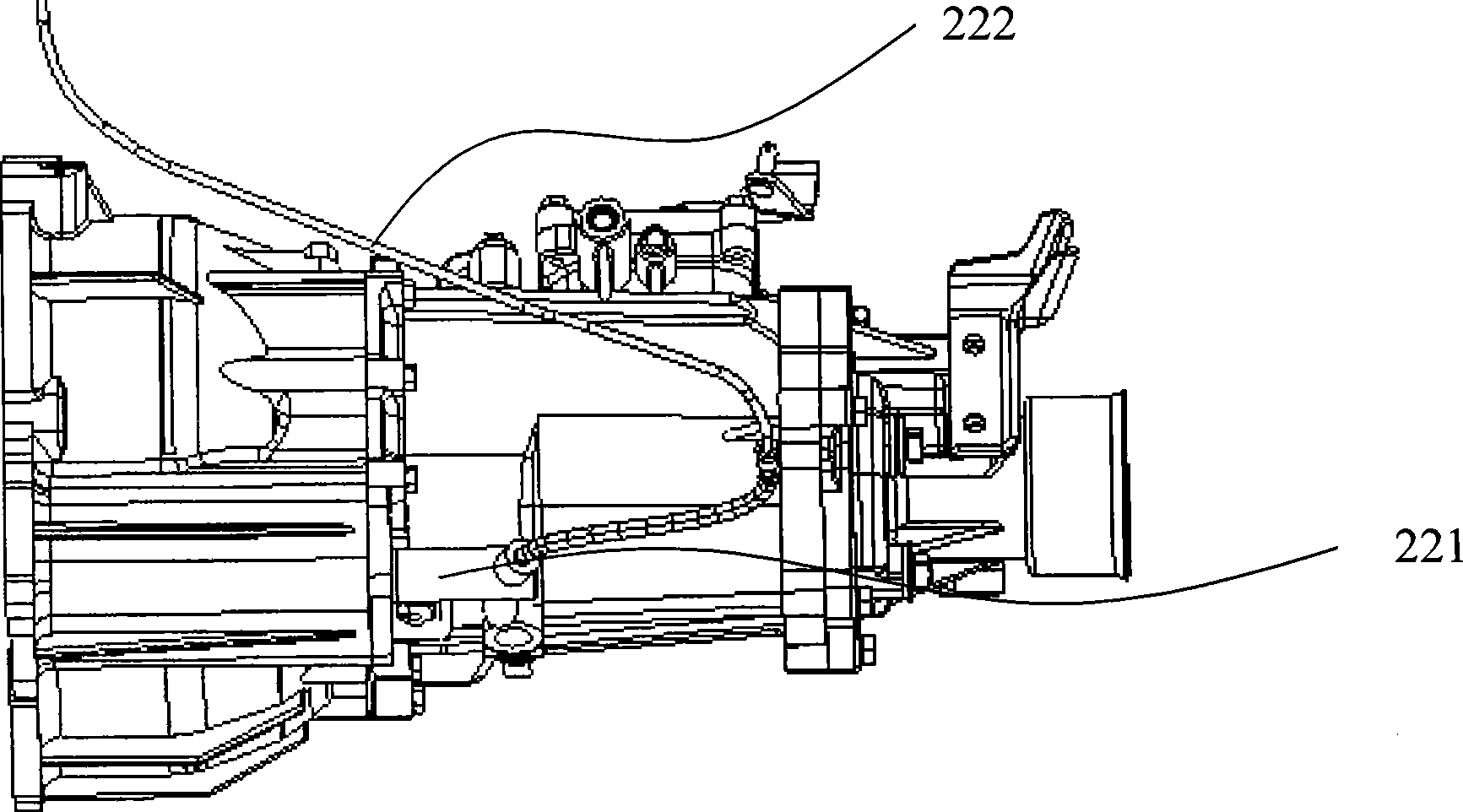

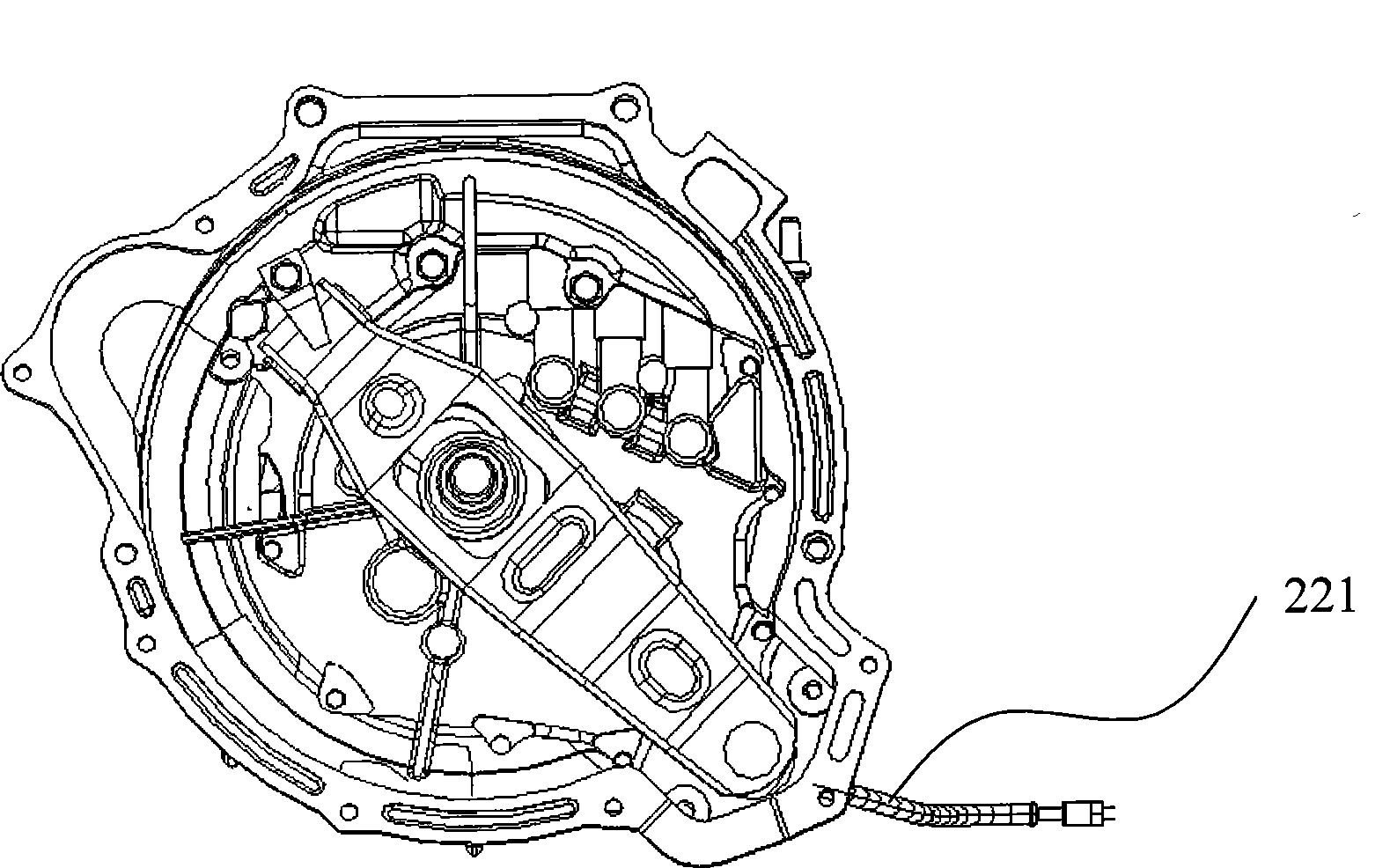

[0017] Such as figure 1 with image 3 As shown, a hydraulically controlled vehicle power transmission mechanism includes an engine 1, a transmission 3 and a clutch 21 arranged between the engine 1 and the transmission 3, and the clutch 21 is connected to a clutch controller 22; the clutch control The device 22 is a hydraulic control actuator, which includes a hydraulic master cylinder 221 and an oil pipe 222 communicating with the internal oil circuit of the master cylinder 221; the hydraulic master cylinder 221 is arranged horizontally. On a vehicle, generally the plane on which the vehicle is located is horizontal. At this time, the axis direction of the clutch 21 and the axis center direction of the master cylinder are both horizontal, and their directions are consistent.

[0018] The oil pipes 222 are freely distributed in the engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com