Capacity-expansion groove gas-liquid disconnecting gear

A technology of a gas-liquid separation device and a capacity expansion tank, which is applied in the field of capacity expansion tanks, and can solve problems such as blockage of mesh holes, time-consuming and labor-intensive, and increased economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

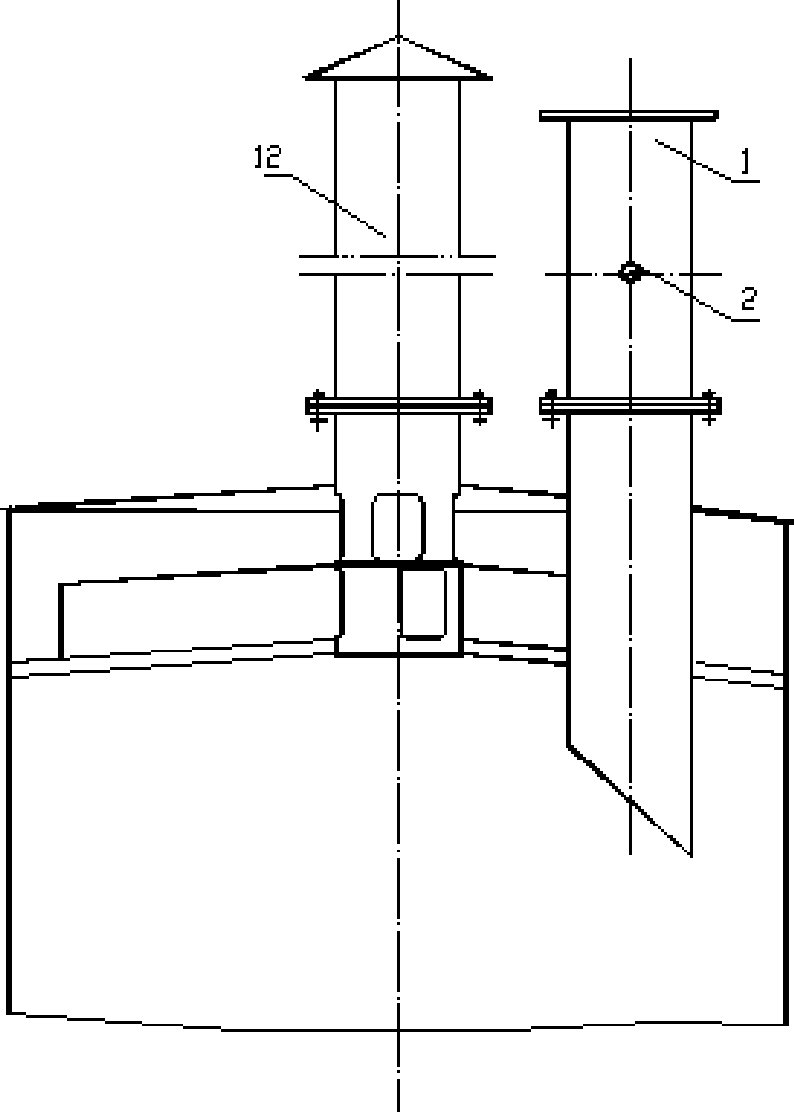

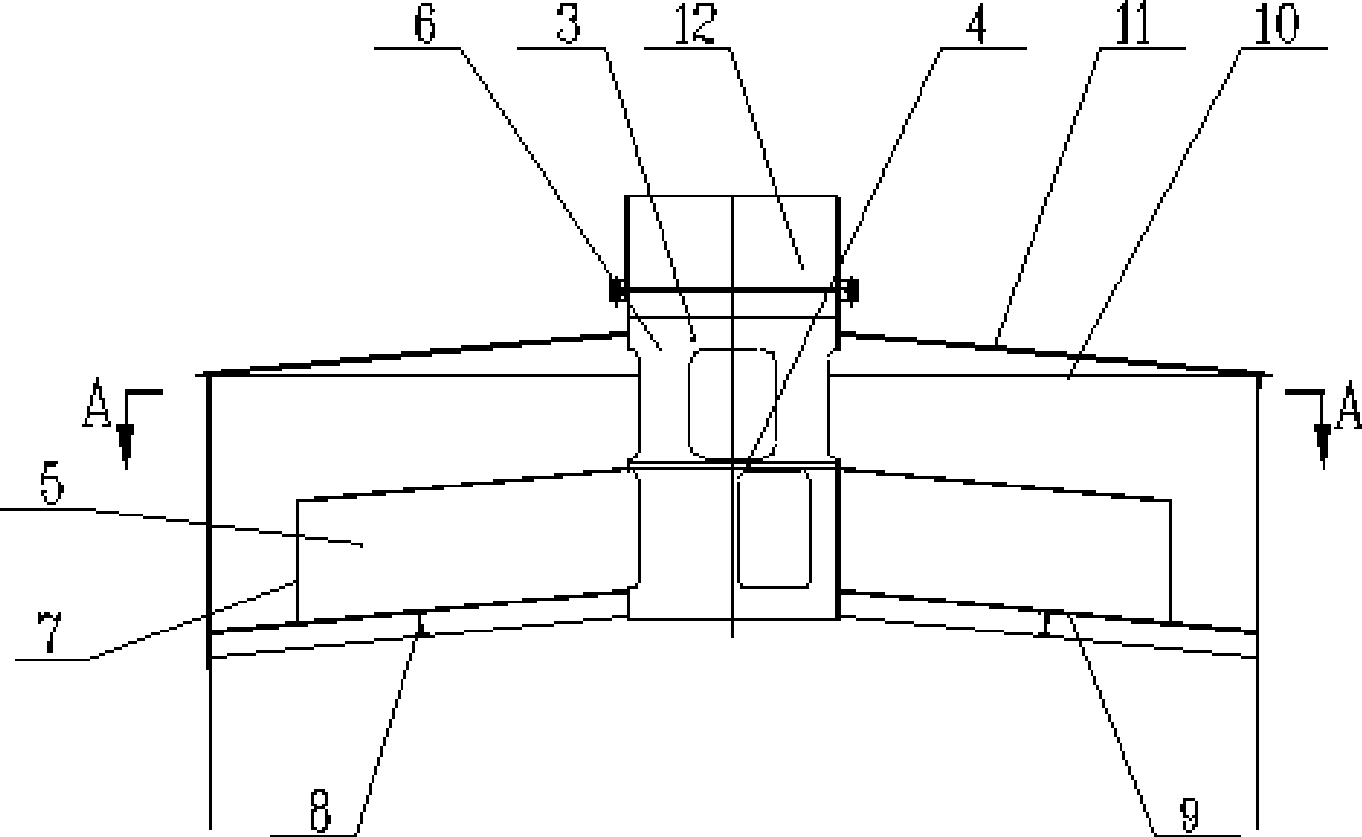

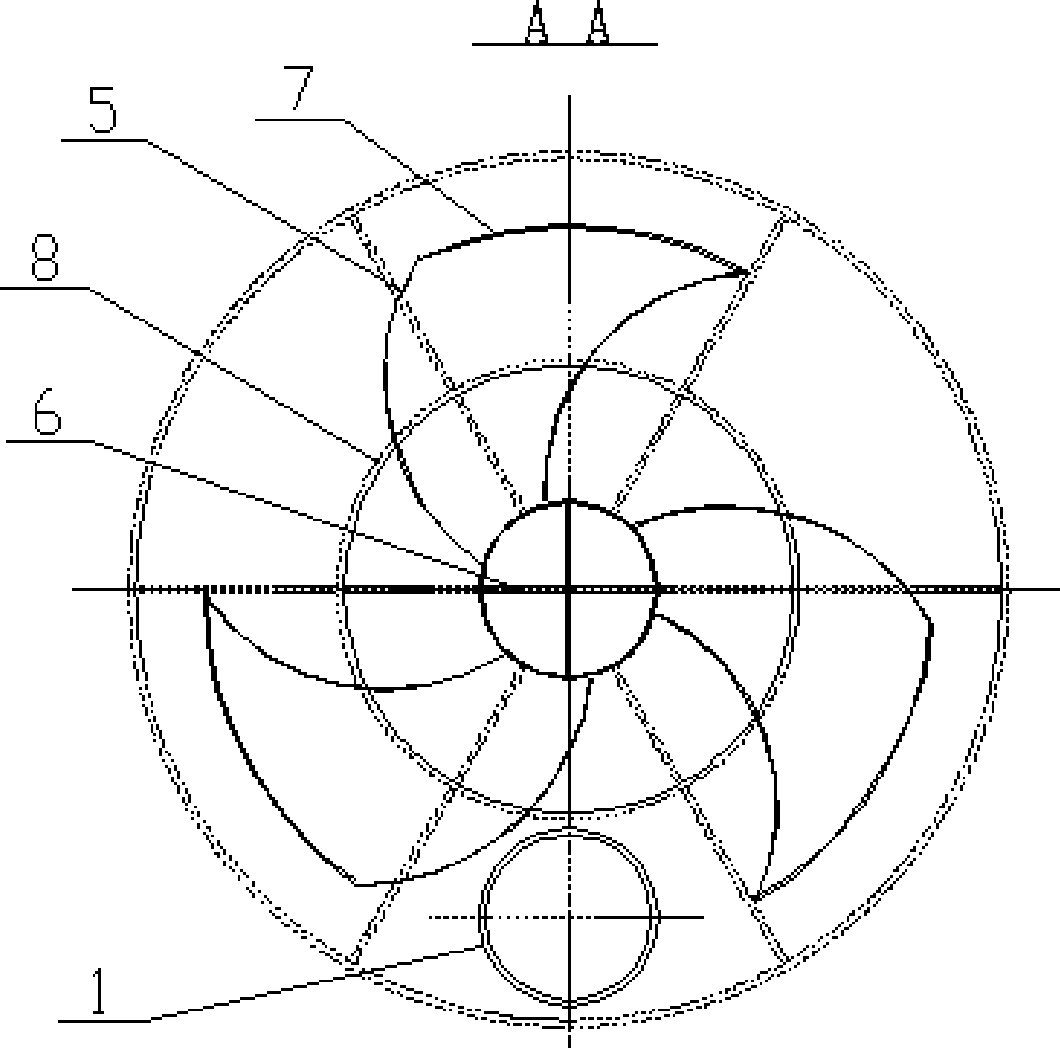

[0013] Embodiments of the present invention: a shower pipe 2 is installed in the middle of the steam inlet pipe 1, the bottom end of the inlet pipe 1 will be lower than the entrance of the cylinder 3, and a blind plate 4 is arranged in the middle of the cylinder 3 to divide the cylinder into two sections. Weld six fan-like blades 5 with a certain height on the periphery of the lower cylinder, and the diameter of the blades will be less than the inner diameter of the tank, so that it has a certain gap. Three rectangular holes are evenly distributed in the middle of the lower cylinder and the blades, four rectangular holes are evenly distributed in the upper cylinder, and a cross steel plate 6 is welded in the middle of the upper cylinder to divide the inner cavity into four small grids . Connect a steel plate 7 at the position of the rectangular hole between the two blades again. The lowermost end is surrounded by I-shaped steel to form a circular body 8, and the I-shaped stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com